8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

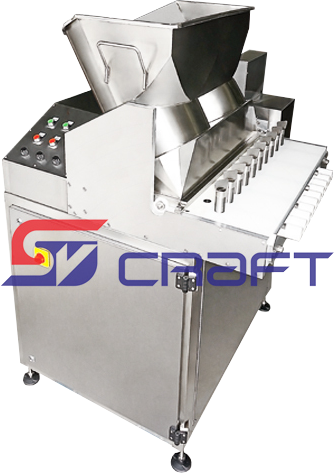

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

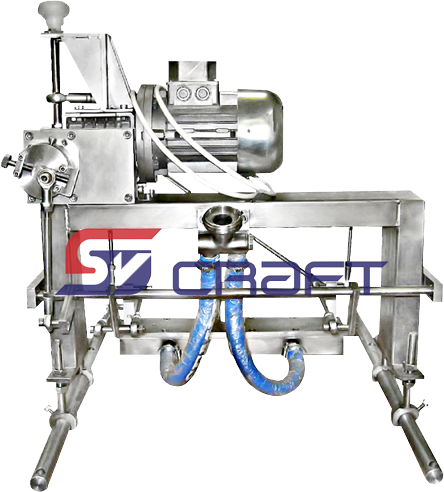

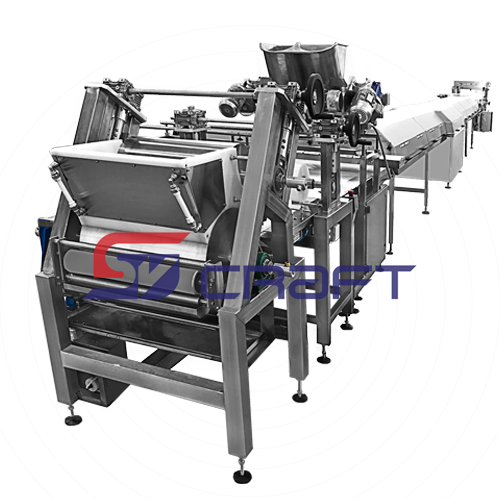

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

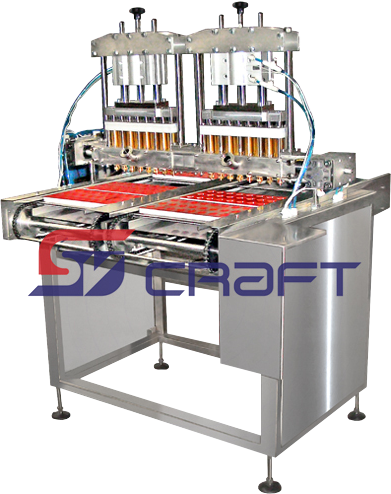

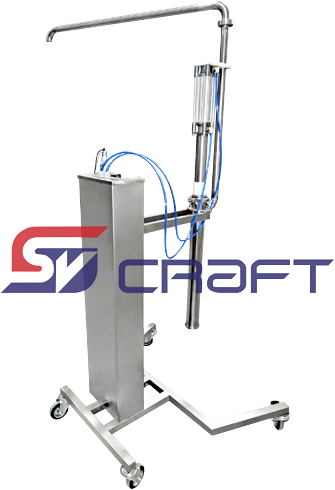

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

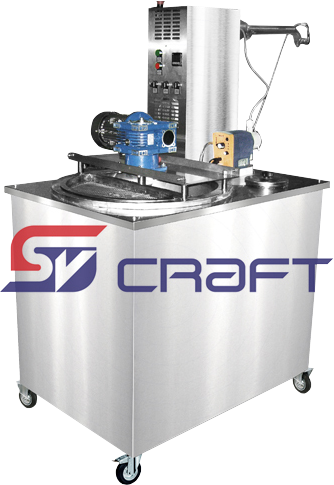

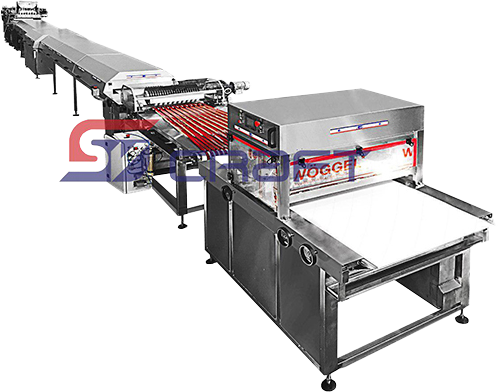

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

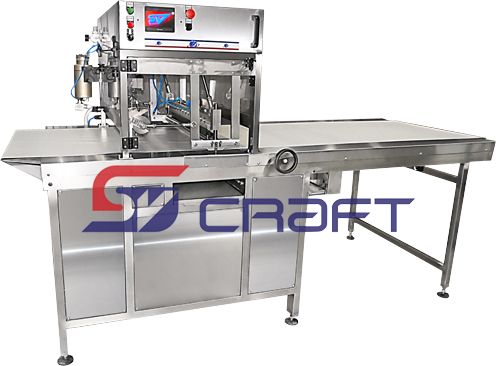

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

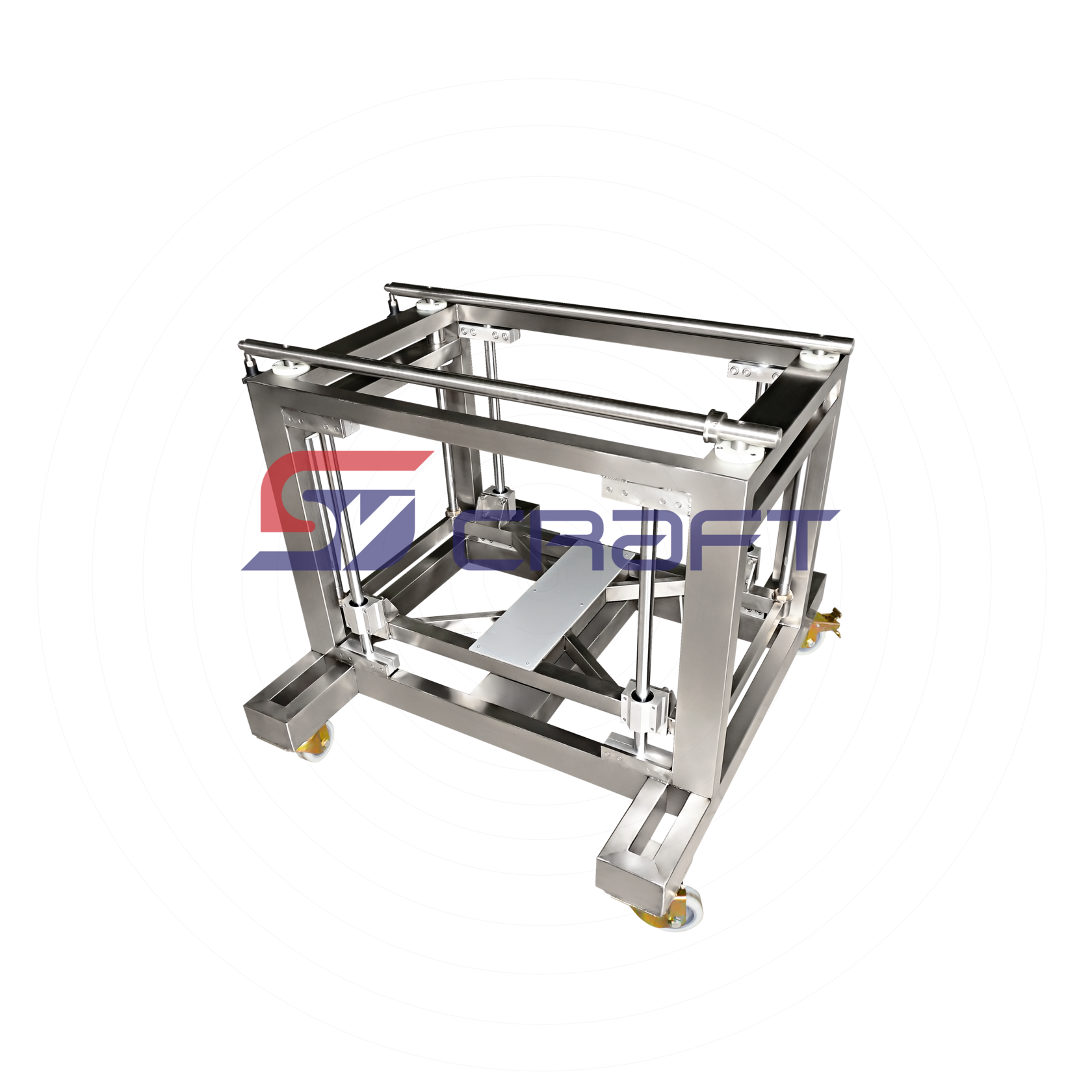

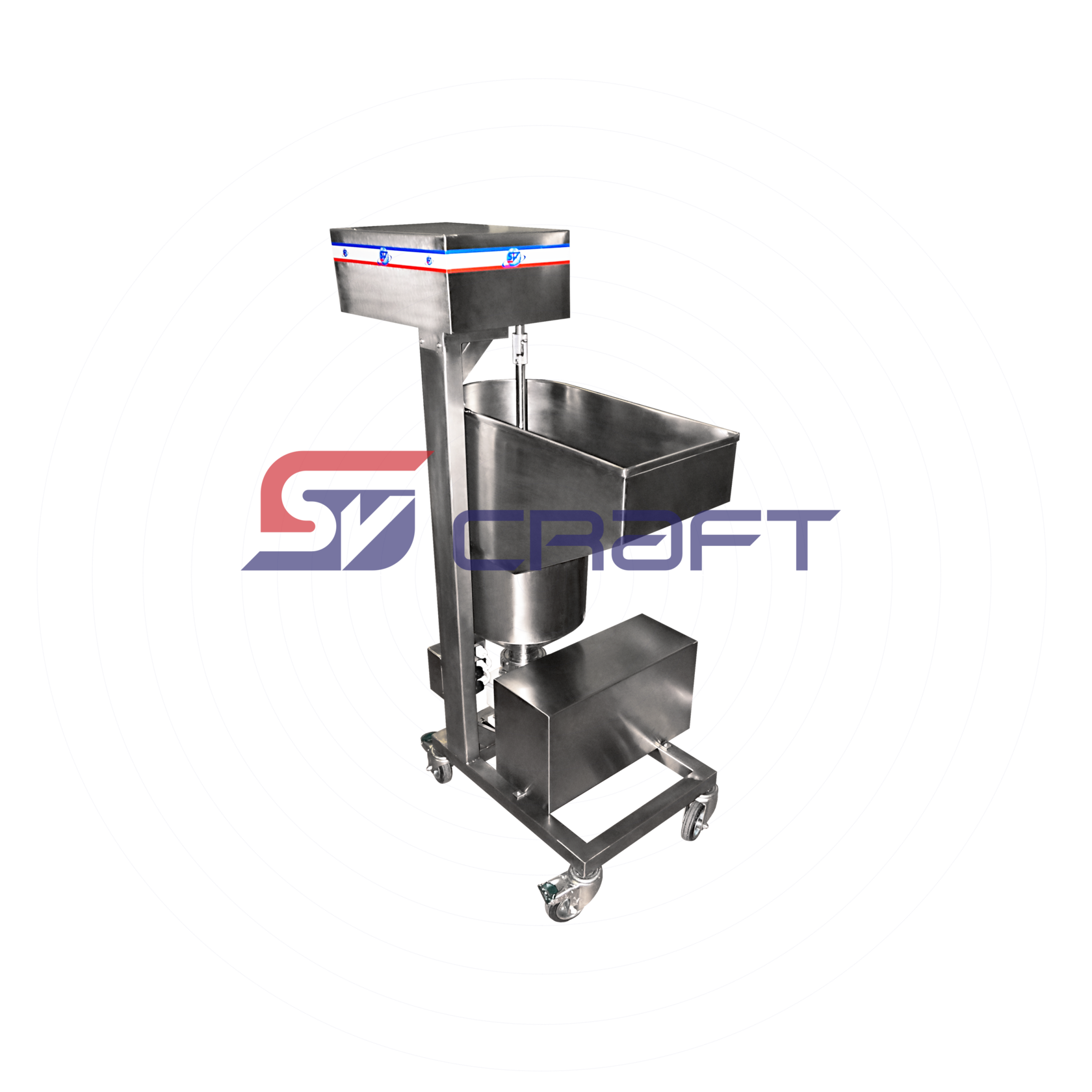

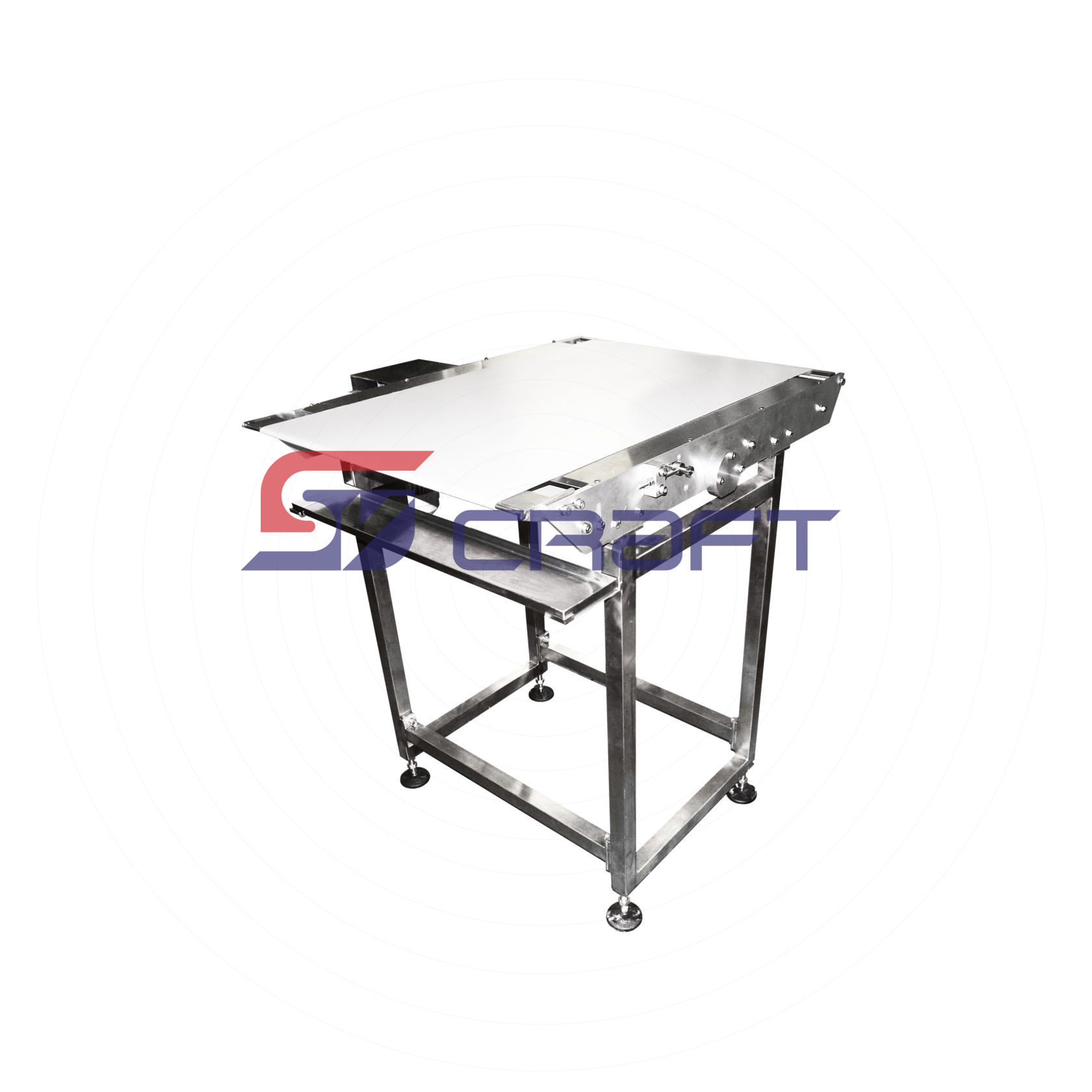

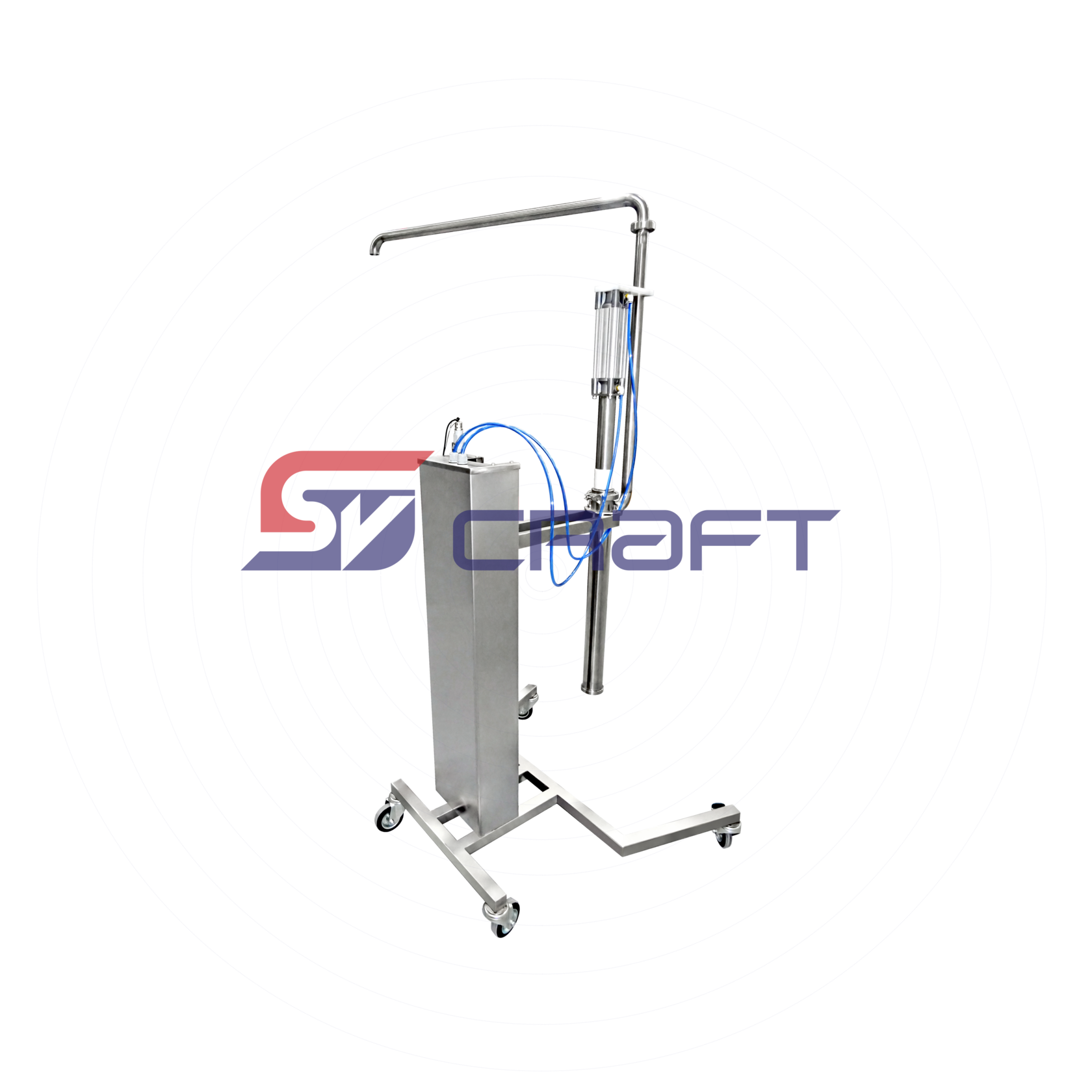

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

DEPOSITING MACHINES FOR COOKIES AND OTHER CONFECTIONERY

Our company offers ready-made solutions for organizing an effective, successful business in the field of confectionery production. Our jigging machines for cookies, gingerbread, marshmallows, and sweets are fully automated and meet all modern requirements for food processing equipment:

High performance

The fundamental component that determines the cost of the final product. The higher your productivity, the lower your costs and the greater your profit.

Easy maintenance

Easy maintenance of the dosing machine - minimum working staff.

Low energy intensity

By reducing energy consumption, the business owner significantly reduces production costs , increasing the profitability of their business.

Universality

The more types of products you can produce, the higher the demand will be . After all, as you know, one type of product quickly becomes boring, the consumer market requires a constant variety of products .

Engineering standards

All electrical, electronics and drive equipment installed on our equipment from the world's leading brands meets all the standards of mechanical engineering

Optimally selected equipment for your confectionery shop will help to withstand high competition in the domestic market, make production highly profitable. Short payback periods for purchased equipment will guarantee the stability of your business.

How RoboForm depositing machines work

How RoboForm depositing machines work

How quickly does the depositing equipment pay off ?

Investments in the development of the enterprise must be returned quickly – this is the most important requirement for modern equipment.

That is why, before you buy a jigging machine , you must carefully read the technical characteristics of the equipment.

RoboForm testers have the following highly effective technical features:

That is why, before you buy a jigging machine , you must carefully read the technical characteristics of the equipment.

RoboForm testers have the following highly effective technical features:

- With the roller type of injection -smooth adjustment of the speed of the rotating nozzles, various options for working with the pan, adjustment of the table movement modes. The capacity is about 270 kg / hour.

- With roller-gear injection-improved ability to adjust the rotation speed of installed attachments, combining different types of jigging in the production of a single product. Performance of medium-sized jigging equipment : up to 270 kg / hour.

- Providing high productivity, our jigging machines for cookies and other confectionery products consume only 1.5 KW / hour. This does not create increased loads on the network, and therefore there is no need to design special three-phase networks in the enterprise.

- The food equipment we offer stores up to 80 recipes in memory that are used constantly.

- Programmable dosing machines allow you to easily copy and create your own recipes , make changes even in the production process, stopping the flow (only 1 row of products will be spoiled!).

- Depositing marmalade or chocolate.

- Depositing cookies (one-, two- color, with filling).

- Formation of stepped and vertically elongated confectionery products.

- Working with a souffle mass.

- Depositing plastic fondant.

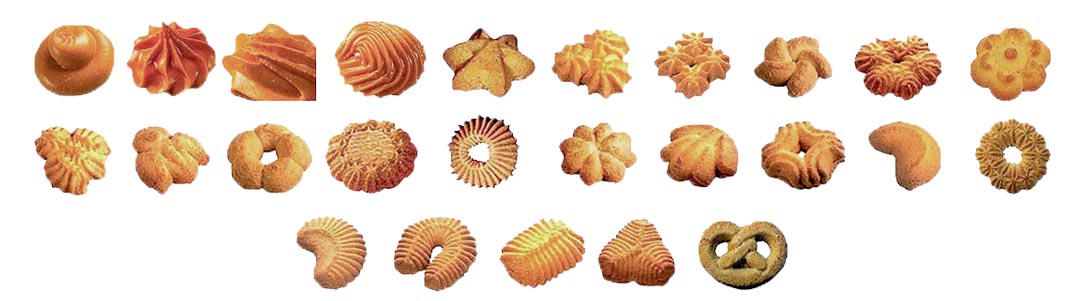

PRODUCT RANGE

To buy a RoboForm jigging machine and determine what equipment performance is required for your shop, please contact our free number for detailed advice

8 800-707-77-32.

We will be happy to tell you about the advantages of each model we produce to make your production as efficient as possible!

8 800-707-77-32.

We will be happy to tell you about the advantages of each model we produce to make your production as efficient as possible!

Free consultation

Free consultation