8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

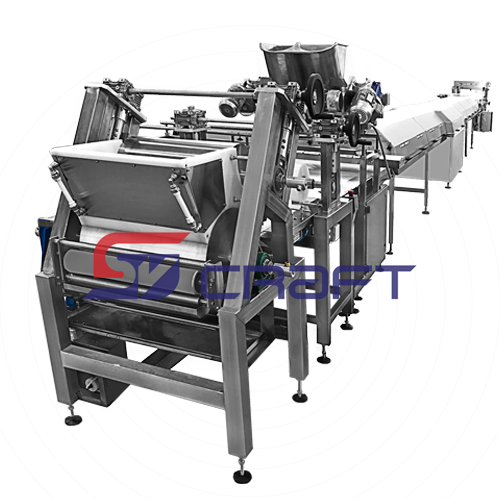

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

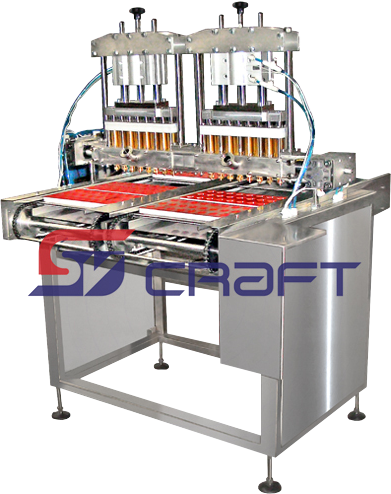

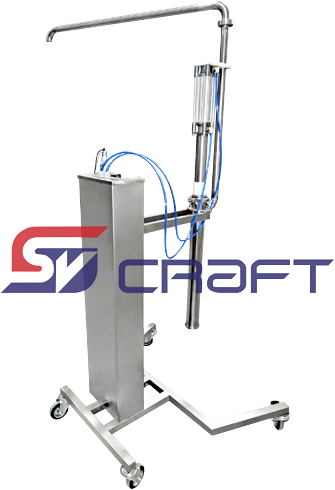

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

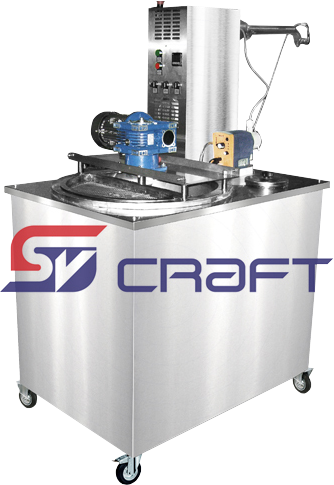

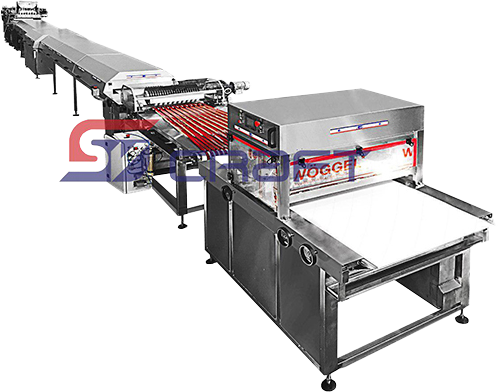

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

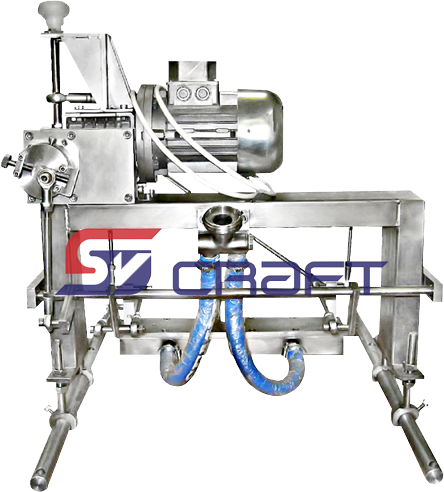

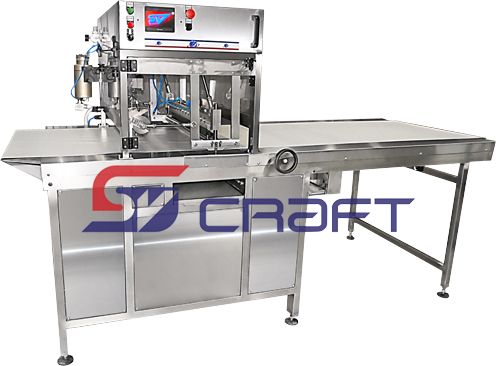

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

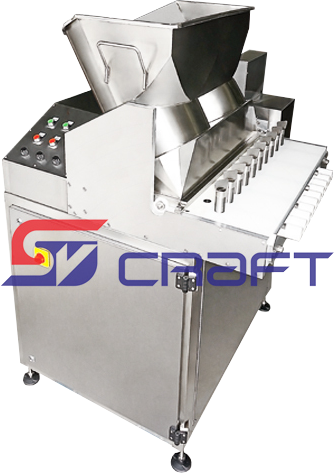

RoboForm - 3D three compartment depositing machine

RoboForm - 3D three compartment depositing machine

Примечание

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

Разработанное в компании SVcraft ПО "шибер курабье" для отсадки печенья курабье

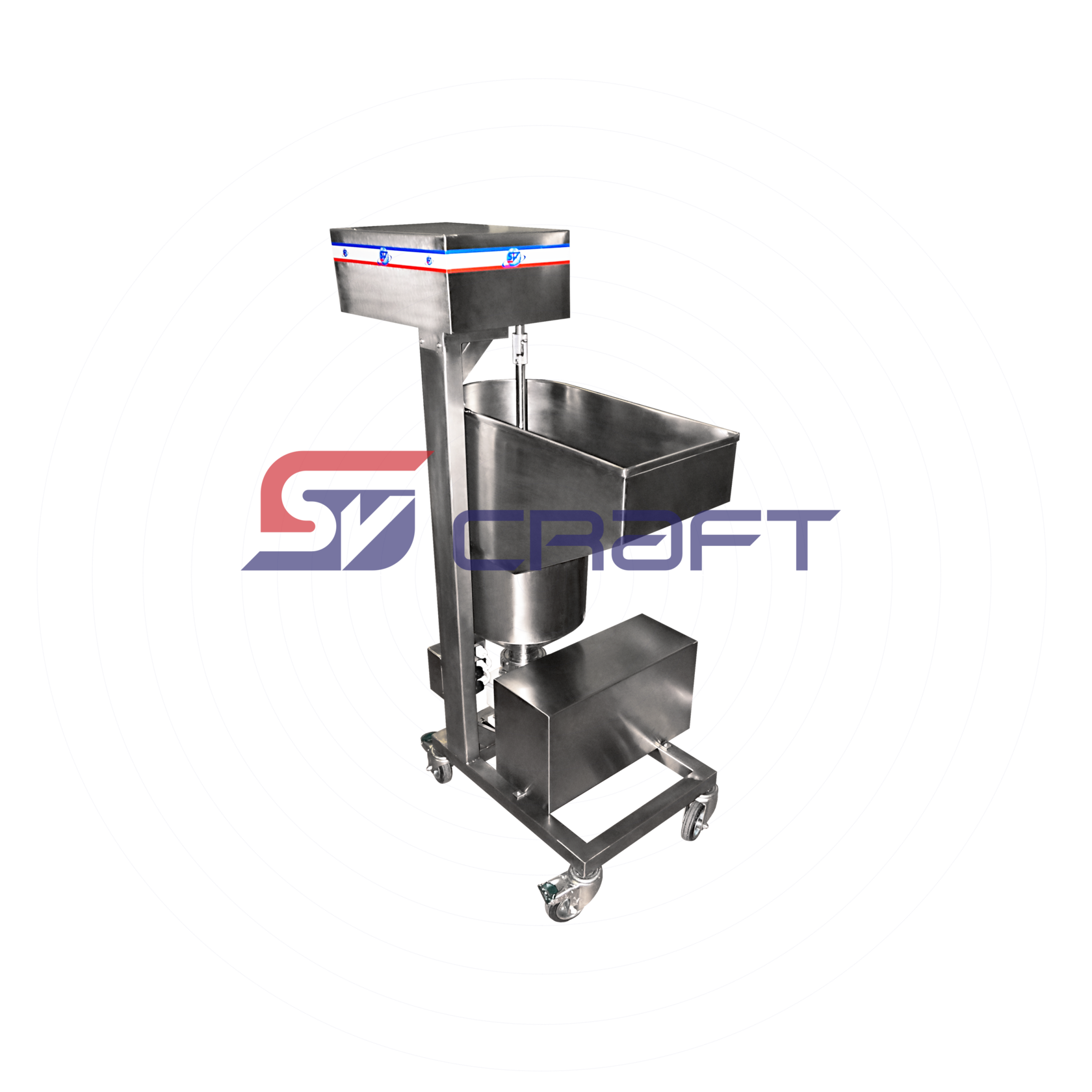

Three - compartment depositing machine manufactures products made from whipped soufflé masses, bicolored biscuits with filling and without it, sweets made from plastic fondant masses, bicolored marshmallow,marshmallow with filling and without it, biscuit and choux products.

Price on request

Customized

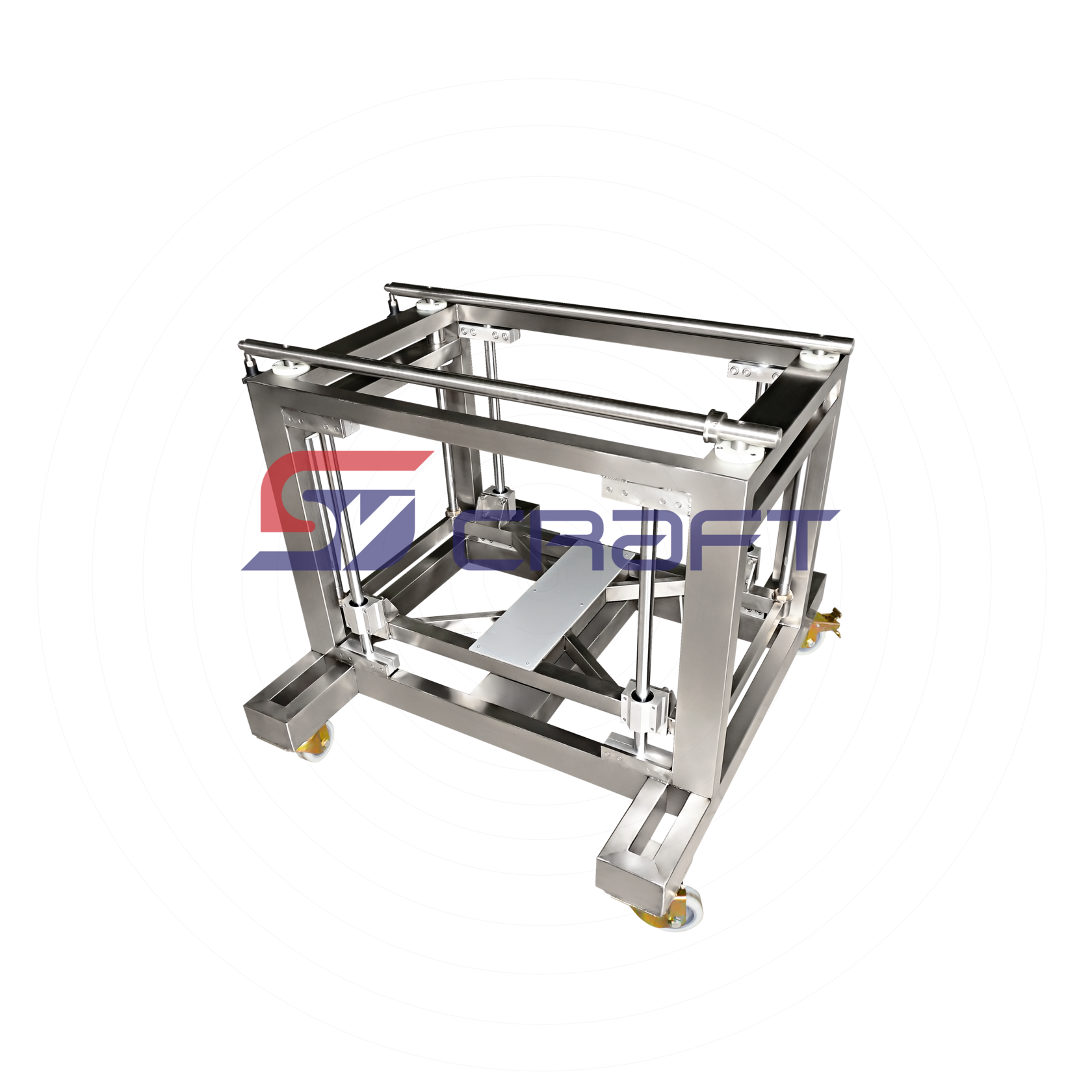

Dough depositing machine- RoboForm - 3D

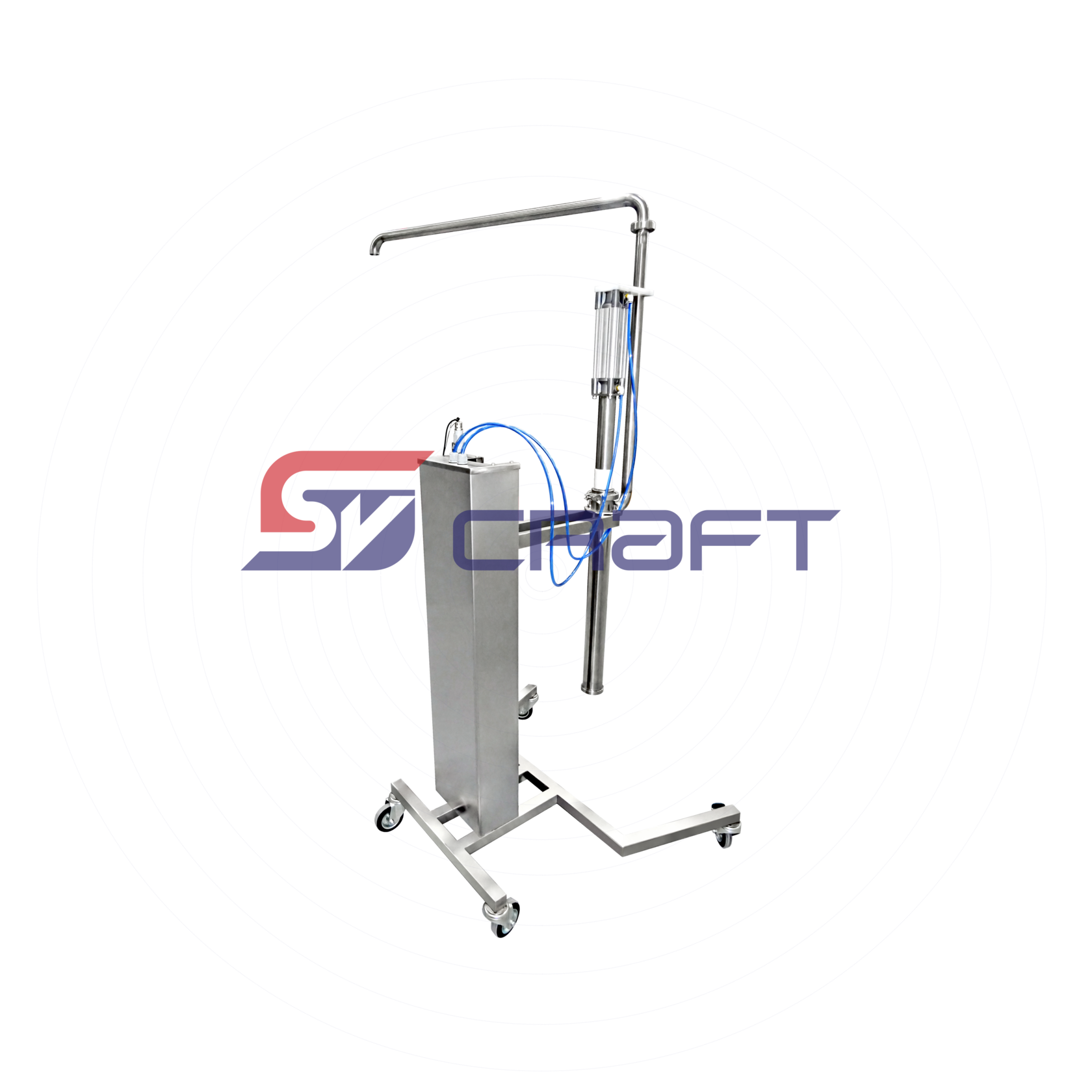

Additional options

bunker heating

wire cutting

feed control gate (plate)

feed control gate (plate) for curabier

Three - compartment depositing machine manufactures products made from whipped soufflé masses, bicolored biscuits with filling and without it, sweets made from plastic fondant masses, bicolored marshmallow,marshmallow with filling and without it, biscuit and choux products.

Price on request

Customized

Dough depositing machine- RoboForm - 3D

Additional options

bunker heating

wire cutting

feed control gate (plate)

feed control gate (plate) for curabier

Оставьте заявку

Products produced on this equipment

Products produced on this equipment

Video

Video

Advantages of RoboForm - 3D

Advantages of RoboForm - 3D

In contrast to the RoboForm and RoboForm-Universal two-bunker machines, the RoboForm-3D complex can work simultaneously with masses of two different colors and plant the filling, both inside the product and outside.

1

Universality

- RoboForm-3D produces products that require one machine for depositing dough, the second for filling the filling.

We have increased productivity and improved the software to eliminate the need to buy two machines and reduce the number of maintenance personnel. SVcraft has specially developed the RoboForm-3D machine for companies with small production areas.

2

Depositing

- The program can contain from 1 to 5 stages of jigging in 9 rows, the fifth stage- a controlled separation, consisting of horizontal and vertical movement.

- Horizontal movement can be oncoming or passing, and vertical-up or down.

3

Gate

- The gate is pressed against the jigging block in the same plane, which eliminates mixing of the masses from the two bins.

- Rotation of the nozzles can occur in both directions, and their speed is regulated.

4

Security

- Safety measures are provided in the test machine in such a way that operator access to the working parts of the equipment is completely excluded.

- When the hopper is opened, the program is not interrupted, but only the rotation of the shafts is blocked . Thus, the result of opening the bin will be a pass on the baking sheet.

5

Program

- Monitors the load on the pump motors.

- Storage of up to 80 recipes with names in Russian, the ability to copy recipes.

- Parameters can be entered at the touch of a button by selecting standard sets for each type of jigging. Such sets are also created very simply: by copying a fragment from an existing recipe.

6

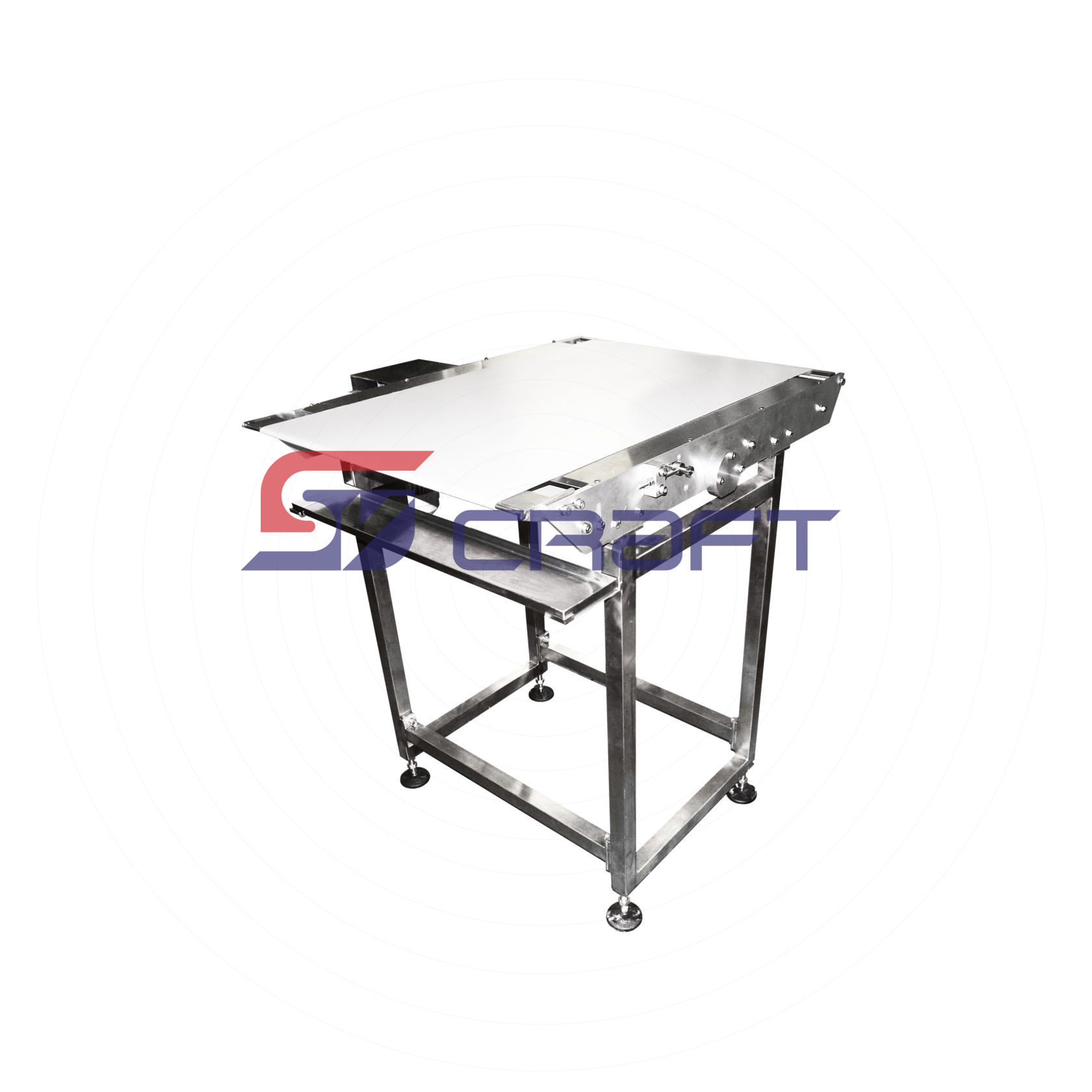

Table

- The speed of the table when depositing can have both smooth and step-by- step control.

- 6 modes of feeding directions , step and pan output.

In contrast to the RoboForm and RoboForm-Universal two-bunker machines, the RoboForm-3D complex can work simultaneously with masses of two different colors and plant the filling, both inside the product and outside.

1

Universality

- RoboForm-3D produces products that require one machine for depositing dough, the second for filling the filling.

We have increased productivity and improved the software to eliminate the need to buy two machines and reduce the number of maintenance staff. SVcraft has specially developed the RoboForm-3D machine for companies with small production areas.

2

Depositing

- The program can contain from 1 to 5 stages of jigging in 9 rows, the fifth stage- a controlled separation, consisting of horizontal and vertical movement.

- Horizontal movement can be oncoming or passing, and vertical movement can be up or down.

3

Nozzles

- The nozzles are pressed against the jigging unit in the same plane, which eliminates mixing of the masses from the two bunkers.

- The rotation of the nozzles can occur in both directions, and their speed is regulated.

4

Security

- Safety measures are provided in the test machine in such a way that operator access to the working parts of the equipment is completely excluded.

- When the hopper is opened, the program is not interrupted, but only the rotation of the shafts is blocked . Thus, the result of opening the bin will be a pass on the baking sheet.

5

Program

- Monitors the load on the pump motors..

- Storage of up to 80 recipes with names in Russian, the ability to copy recipes.

- Parameters can be entered at the touch of a button by selecting standard sets for each type of jigging. Such sets are also created very simply: by copying a fragment from an existing recipe.

6

Table

- The speed of movement of the table when depositing can have both smooth and step-by- step control.

- 6 modes of feeding directions , pitch and baking tray delivery.

Technical parameters

Technical parameters