8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

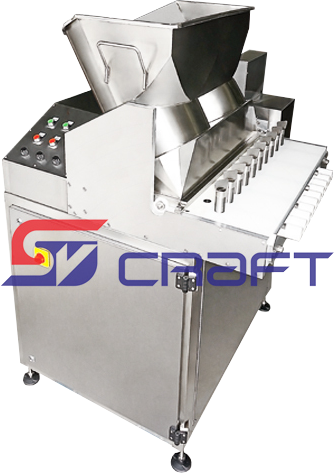

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

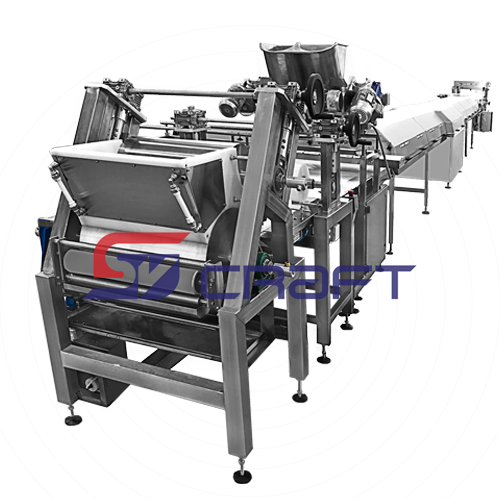

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

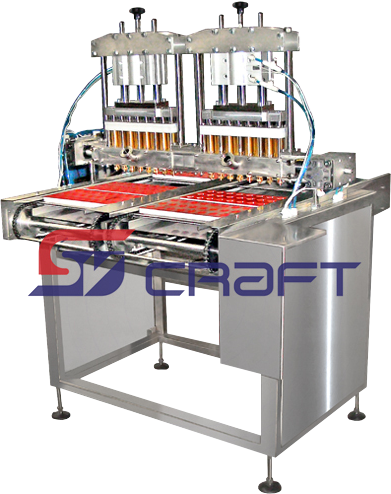

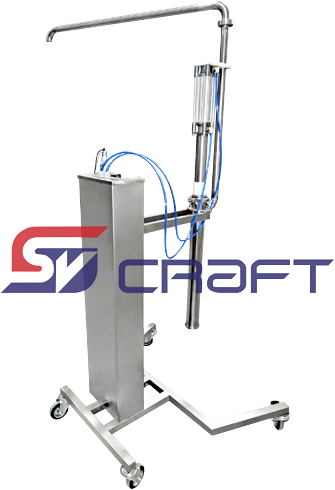

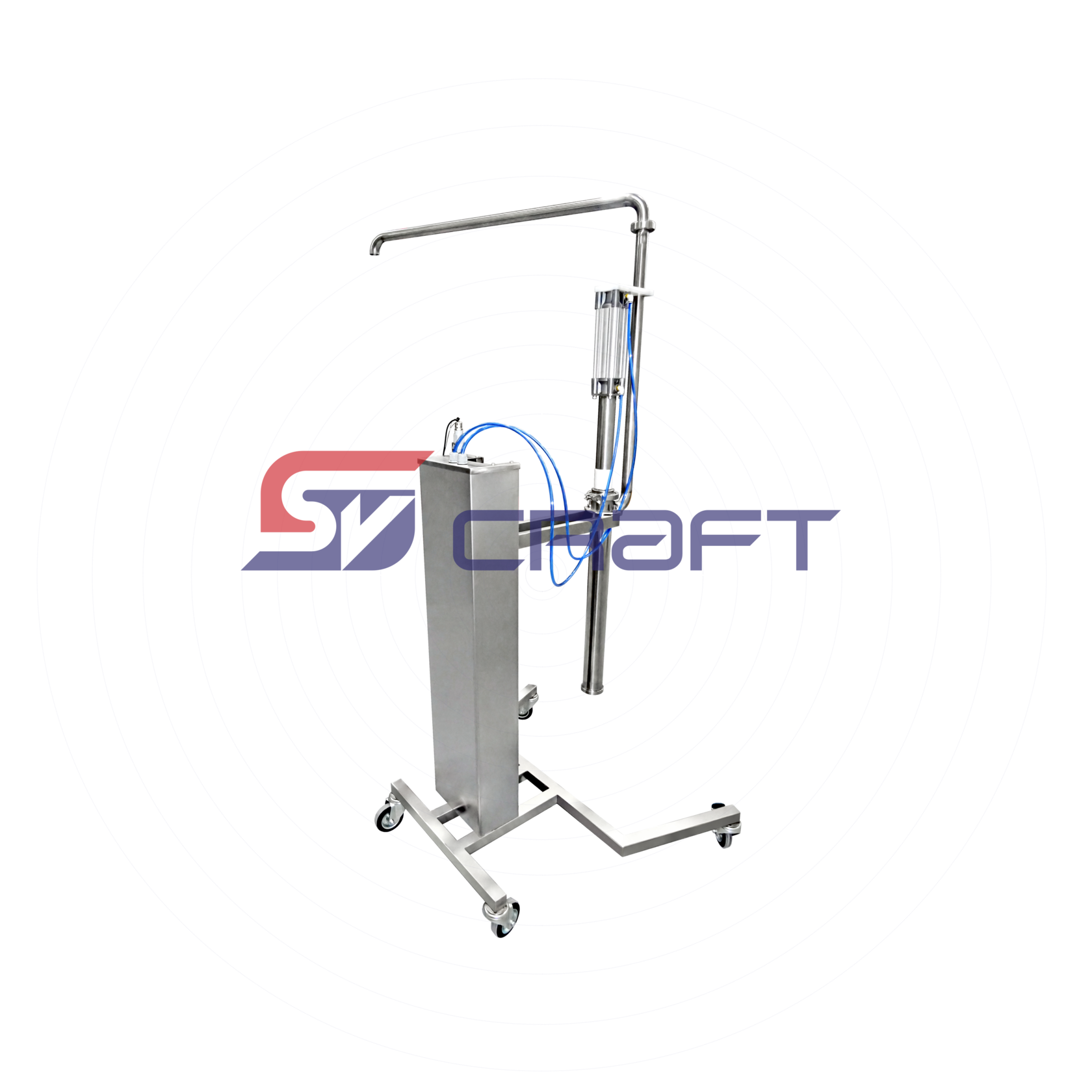

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

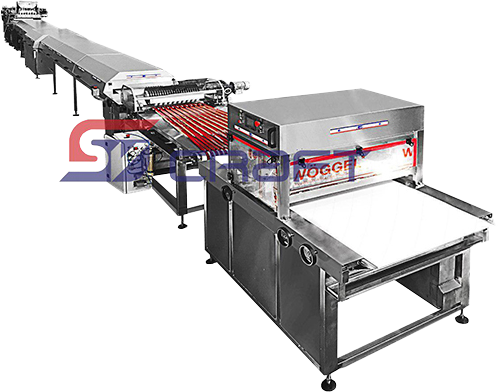

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

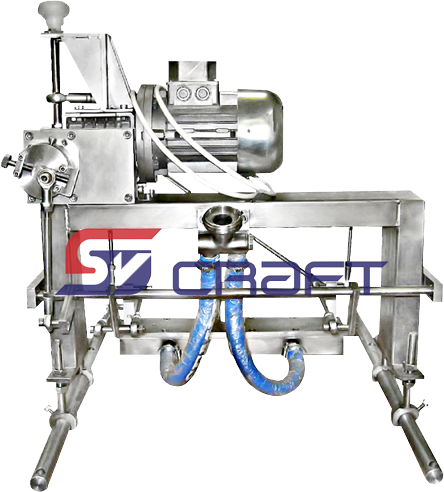

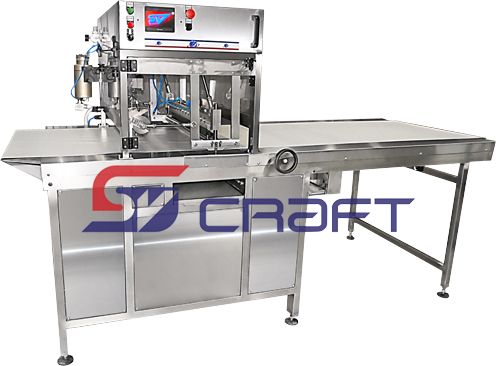

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

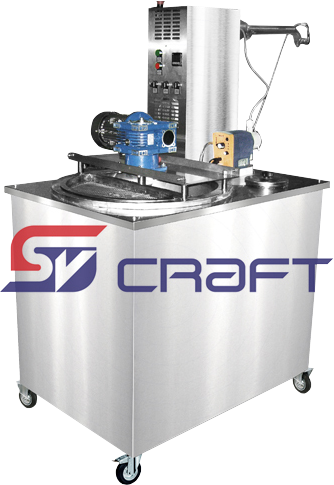

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

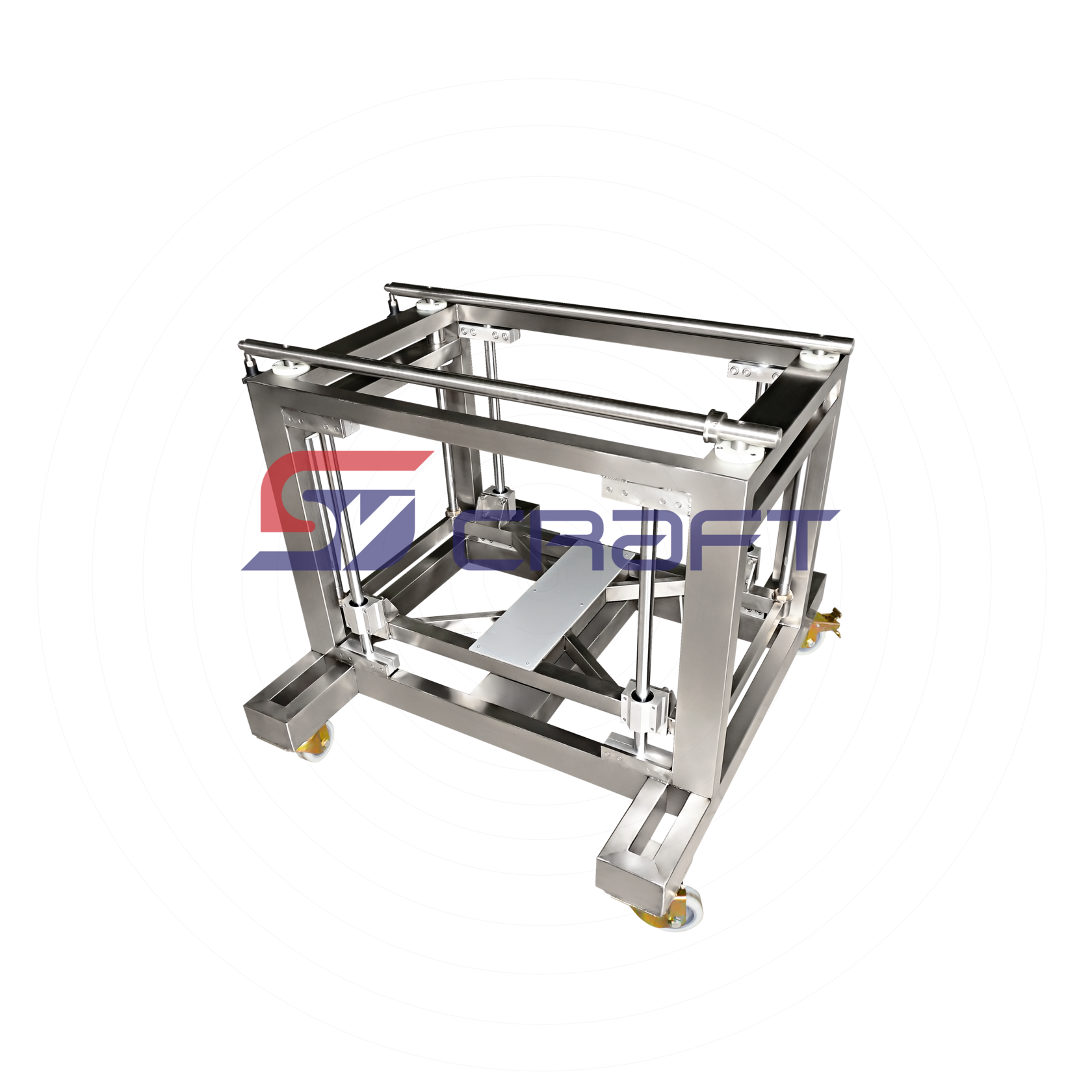

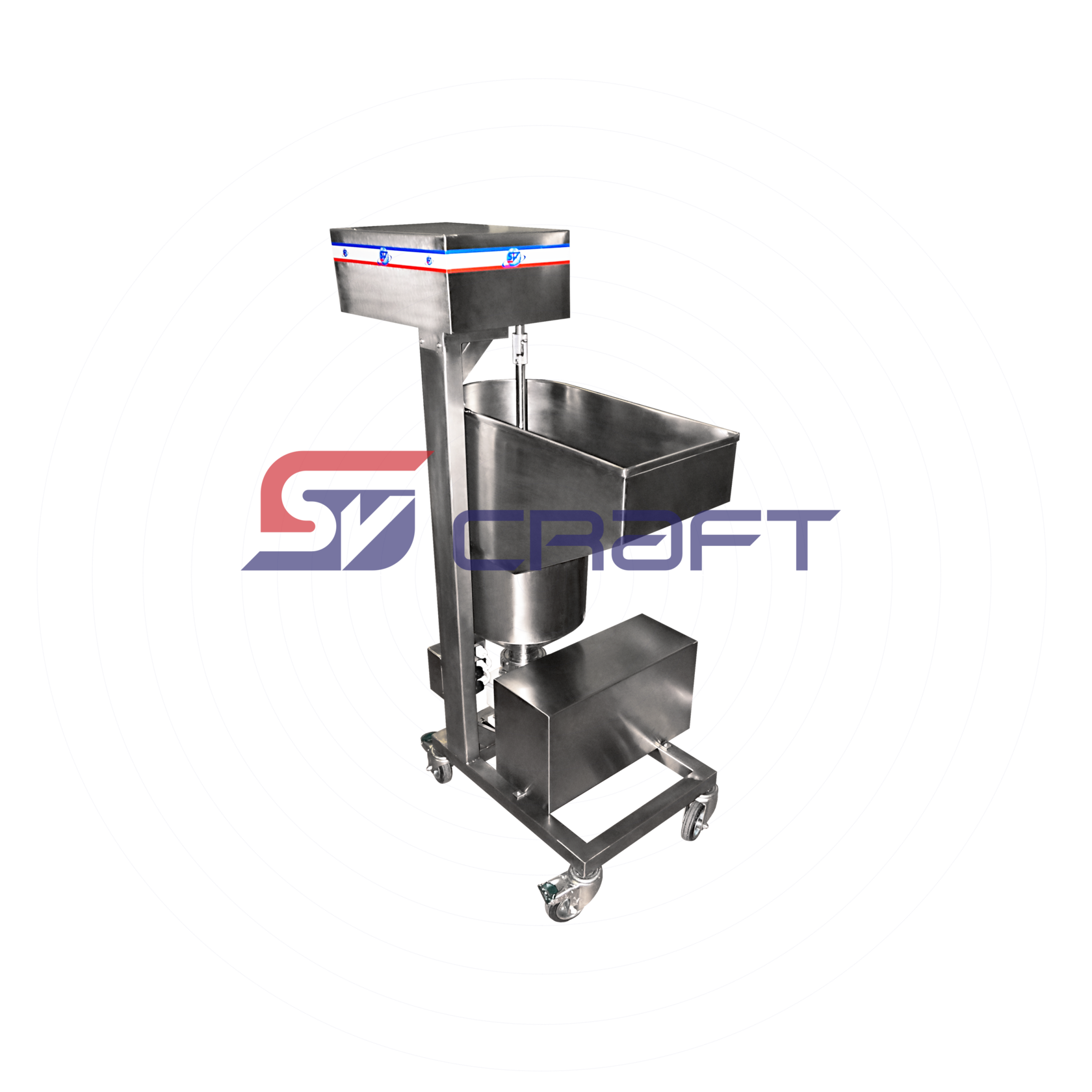

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

Depositing machine – RoboForm-Universal

Depositing machine – RoboForm-Universal

Примечание

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

Разработанное в компании SVcraft ПО "шибер курабье" для отсадки печенья курабье

Double- bunker roller -gear depositing

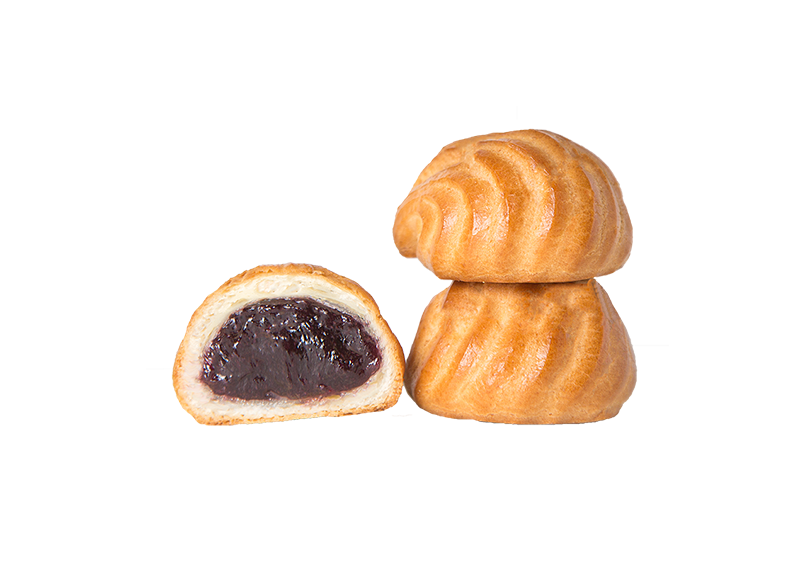

the machine is designed for production

two- color cookies , cookies with filling as

inside the product and outside, two- color marshmallows,

marshmallow with filling, made of choux pastry,

muffins, also allows you to cast sponge cakes

mass on a baking sheet and into molds, release candy

from plastic fondant, whipped products

souffle masses.

the machine is designed for production

two- color cookies , cookies with filling as

inside the product and outside, two- color marshmallows,

marshmallow with filling, made of choux pastry,

muffins, also allows you to cast sponge cakes

mass on a baking sheet and into molds, release candy

from plastic fondant, whipped products

souffle masses.

Price on request

In stock

Additional options

bunker heating

wire cutting

feed control

gate (plate)

gate (plate)

feed control gate (plate) for curabier

Awards

Double- bunker roller -gear jigging

the machine is designed for production

two- color cookies , cookies with filling as

inside the product and outside, two- color marshmallows,

marshmallow with filling, made of choux pastry,

muffins, also allows you to cast sponge cakes

mass on a baking sheet and into molds, release candy

from plastic fondant, whipped products

souffle masses.

the machine is designed for production

two- color cookies , cookies with filling as

inside the product and outside, two- color marshmallows,

marshmallow with filling, made of choux pastry,

muffins, also allows you to cast sponge cakes

mass on a baking sheet and into molds, release candy

from plastic fondant, whipped products

souffle masses.

Price on request

In stock

Additional options

bunker heating

wire cutting

feed control gate (plate)

feed control gate (plate) for curabier

Awards

Оставьте заявку

Products produced on this equipment

Products produced on this equipment

Video

Video

Basic features of RoboForm-Universal

Basic features of RoboForm-Universal

In comparison with RoboForm, the RoboForm-Universal uses the design of a roller-gear jigging unit with separate drives for the delivery shafts and a metering pump for working with liquid and sand dough.

In comparison with the roller block of jigging, VSH. the block has an advantage: increased productivity, accuracy of product dosing (makes it possible to get a calibrated product), does not injure the mass, eliminates unnecessary hanging, allows you to cast a layer of sponge cake or souffle on a baking sheet, and set the dough for muffins. Allows you to work with a wider range of weights, from liquid to tight, rich. The stability of the jigging does not depend on the amount of mass in the hopper.

In comparison with the roller block of jigging, VSH. the block has an advantage: increased productivity, accuracy of product dosing (makes it possible to get a calibrated product), does not injure the mass, eliminates unnecessary hanging, allows you to cast a layer of sponge cake or souffle on a baking sheet, and set the dough for muffins. Allows you to work with a wider range of weights, from liquid to tight, rich. The stability of the jigging does not depend on the amount of mass in the hopper.

1

Roller-gear unit

- A jigging unit with enlarged rolls and a gear pump evenly distributes the pressure on the nozzles. Each output has a separate pair of gears. The ability to work with a tightened and rich mass, which increases the product range. A wide grip of the dough , expanded and straightened channels for passing the test eliminates the need to manually push the mass , resulting in increased productivity.

- The optimal cut height of the bins , as well as the design with a minimum number of protruding parts , make it much easier to load raw materials and use the machine.

2

Program

- Monitors the load on the engines.

- Storage of up to 80 recipes with names in Russian, the ability to copy recipes.

- Parameters can be entered at the touch of a button by selecting standard sets for each type of jigging. Such sets are also created very simply: by copying a fragment from an existing recipe.

3

Security

- Safety measures are provided in the test machine in such a way that operator access to the working parts of the equipment is completely excluded.

- When the hopper is opened, the program is not interrupted, but only the drive of the jigging head is blocked. Thus, the result of opening the bin will be a pass on the baking sheet.

4

Gate

- The gate is pressed against the jigging block in the same plane, which eliminates mixing of the masses from the two bunkers.

- The rotation of the nozzles can occur in both directions, and their speed is regulated.

5

Depositing

- The program can contain from 1 to 4 stages of deposition in 9 rows, the fifth stage is a controlled separation consisting of horizontal and vertical movement .

- Horizontal movement can be oncoming or passing, and vertical movement can be up or down.

6

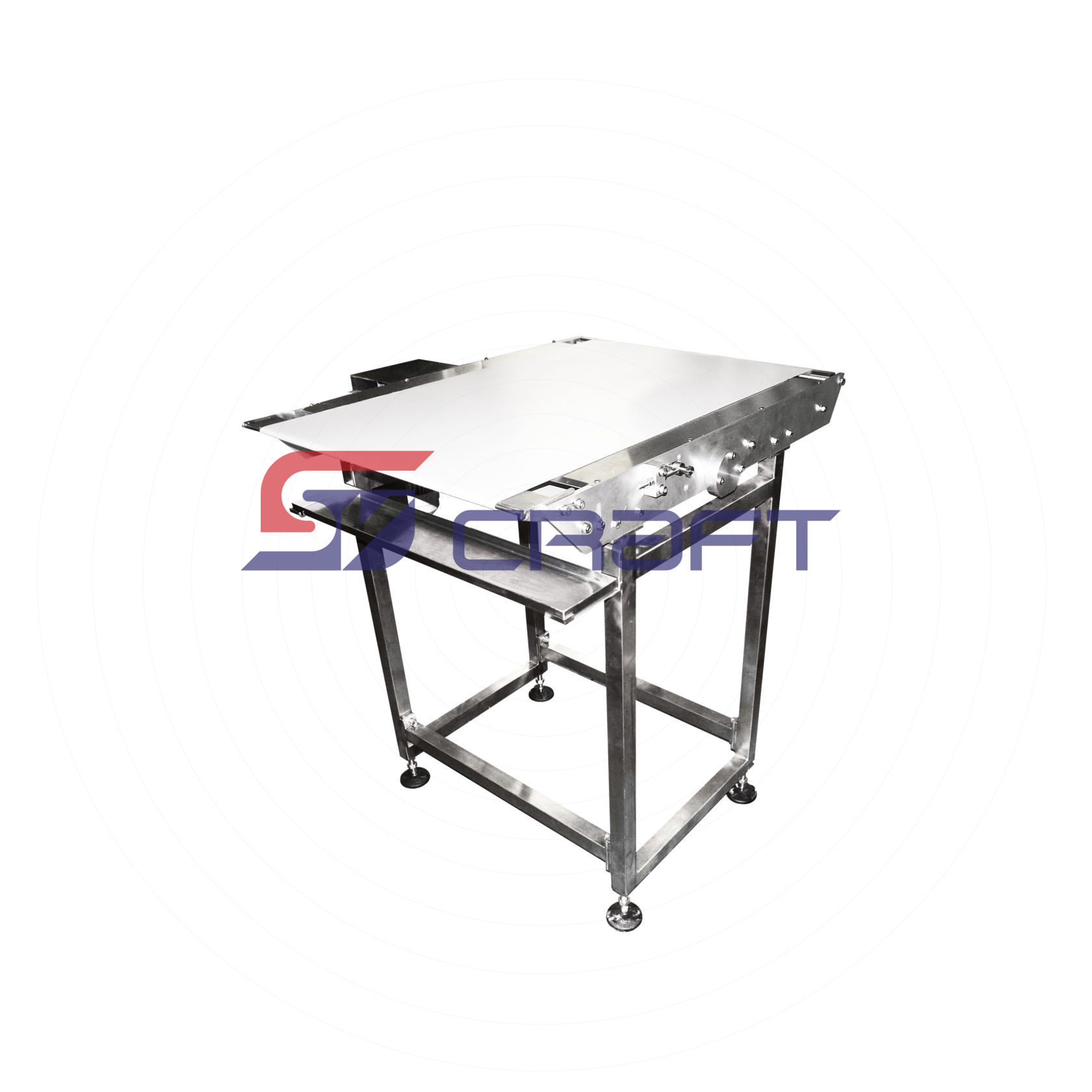

Table

- The speed of the table when depositing can have both smooth and step-by- ste p control.

- 6 modes of feeding directions , pitch and baking tray delivery.

In comparison with RoboForm, the RoboForm-Universal uses the design of a roller-gear jigging unit with separate drives for the delivery shafts and a metering pump for working with liquid and sand dough.

In comparison with the roller block of jigging, VSH. the block has an advantage: increased productivity, accuracy of product dosing (makes it possible to get a calibrated product), does not injure the mass, eliminates unnecessary hanging, allows you to cast a layer of sponge cake or souffle on a baking sheet, and set the dough for muffins. Allows you to work with a wider range of weights, from liquid to tight, rich. The stability of the jigging does not depend on the amount of mass in the hopper.

In comparison with the roller block of jigging, VSH. the block has an advantage: increased productivity, accuracy of product dosing (makes it possible to get a calibrated product), does not injure the mass, eliminates unnecessary hanging, allows you to cast a layer of sponge cake or souffle on a baking sheet, and set the dough for muffins. Allows you to work with a wider range of weights, from liquid to tight, rich. The stability of the jigging does not depend on the amount of mass in the hopper.

1

Roller-gear unit

- A jigging unit with enlarged rolls and a gear pump evenly distributes the pressure on the nozzles. Each output has a separate pair of gears. The ability to work with a tightened and rich mass increases the product range. A wide grip of the dough , expanded and straightened channels for passing the test eliminates the need to manually push the mass , resulting in increased productivity.

- The optimal cut height of the bins , as well as the design with a minimum number of protruding parts , make it much easier to load raw materials and use the machine.

2

Program

- Monitors the load on the pump motors.

- Storage of up to 80 recipes with names in Russian, the ability to copy recipes.

- Parameters can be entered at the touch of a button by selecting standard sets for each type of jigging. Such sets are also created very simply: by copying a fragment from an existing recipe.

3

Security

- Safety measures are provided in the test machine in such a way that operator access to the working parts of the equipment is completely excluded.

- When the hopper is opened, the program is not interrupted, but only the jigging head drive is blocked. Thus, the result of opening the bin will be a pass on the baking sheet.

4

Gate

- Шибер прижимается к отсадочному блоку в одной плоскости, благодаря чему исключается смешивание масс из двух бункеров.

- Вращение насадок может происходить в обе стороны, а их скорость регулируется.

5

Depositing

- The program can contain from 1 to 4 stages of deposition in 9 rows, the fifth stage is a controlled separation consisting of horizontal and vertical movement .

- Horizontal movement can be oncoming or passing, and vertical movement can be up or down.

6

Table

- The speed of the table when depositing can have both smooth and step-by- step control..

- 6 modes of feeding directions , pitch and baking tray delivery

Technical parameters

Technical parameters