8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

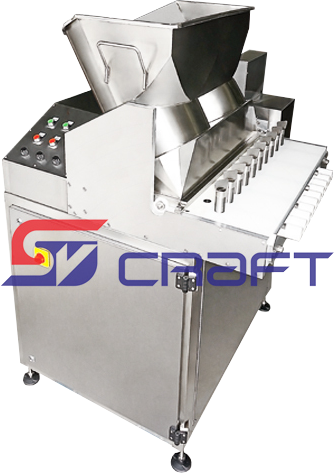

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

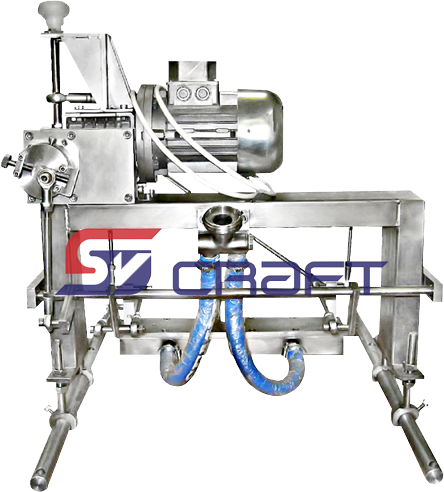

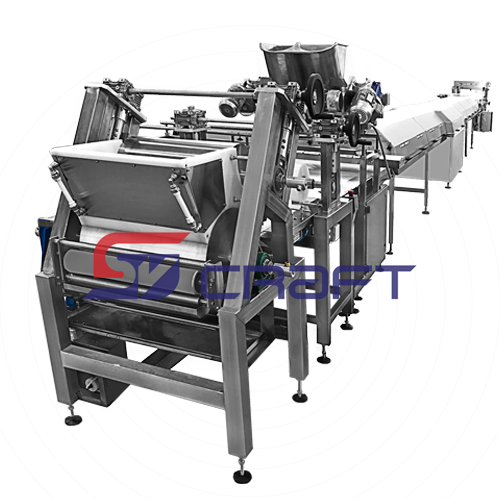

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

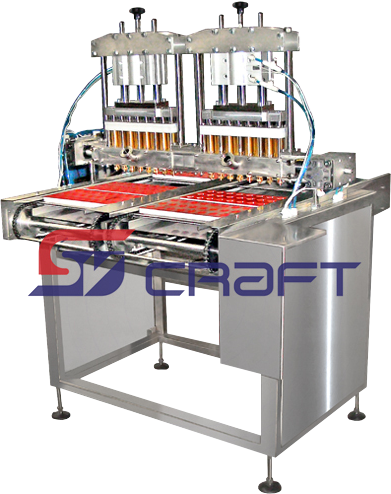

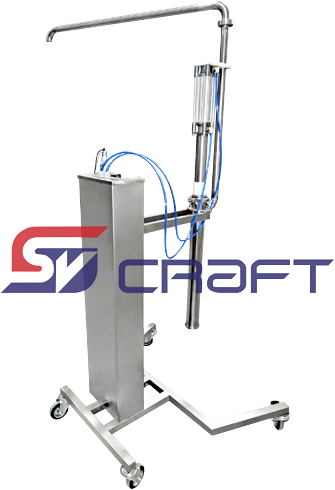

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

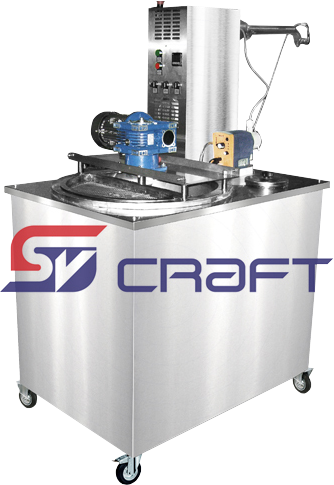

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

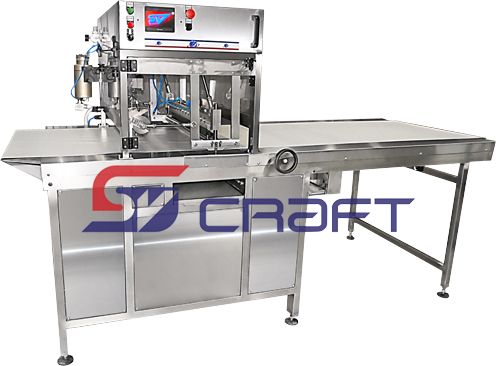

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

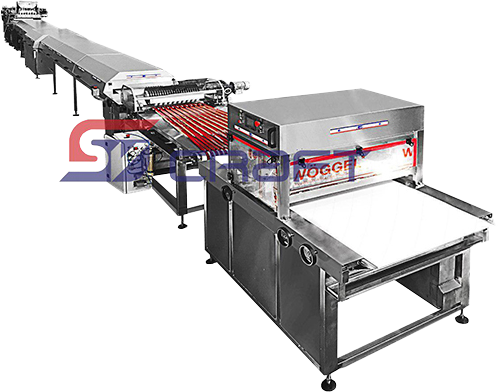

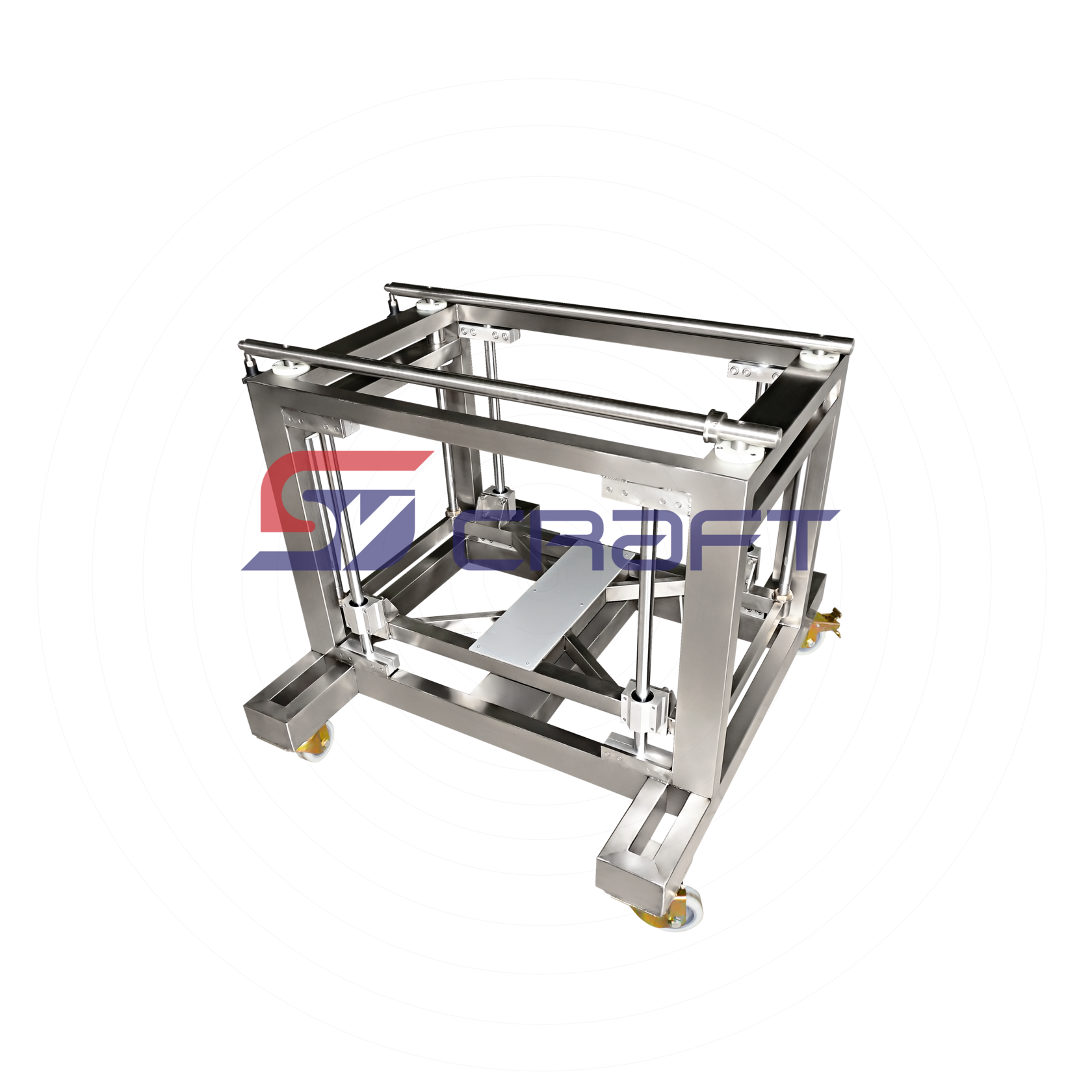

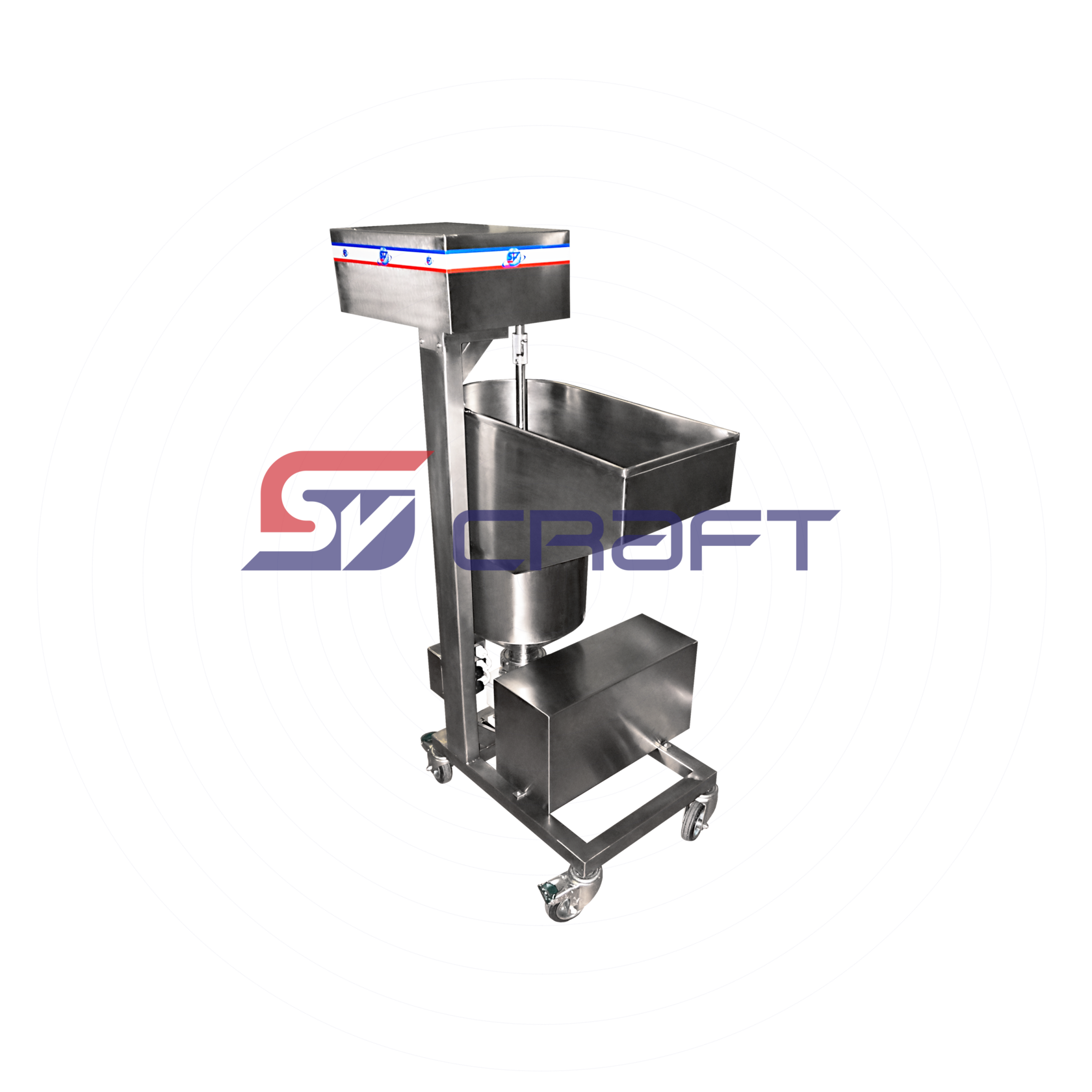

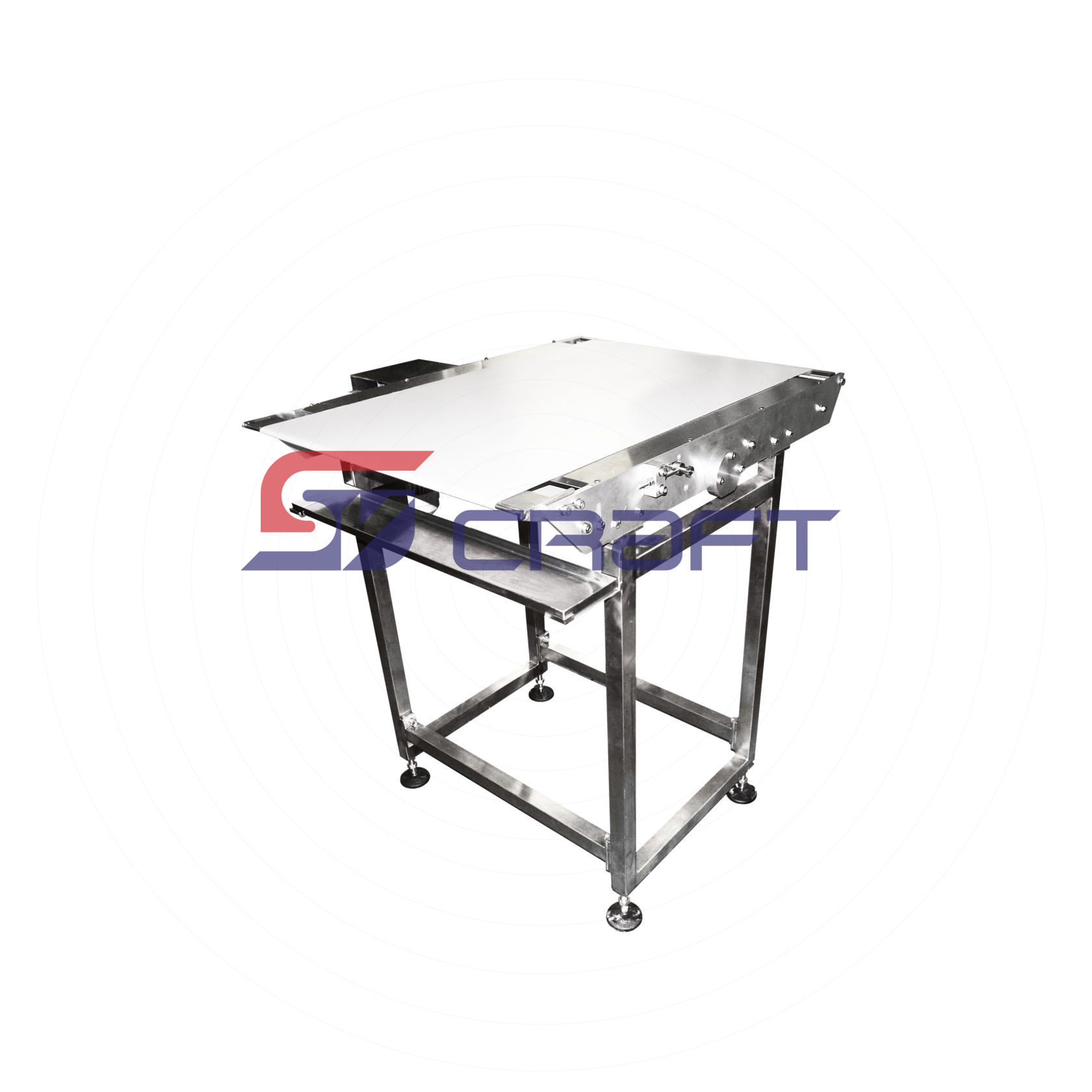

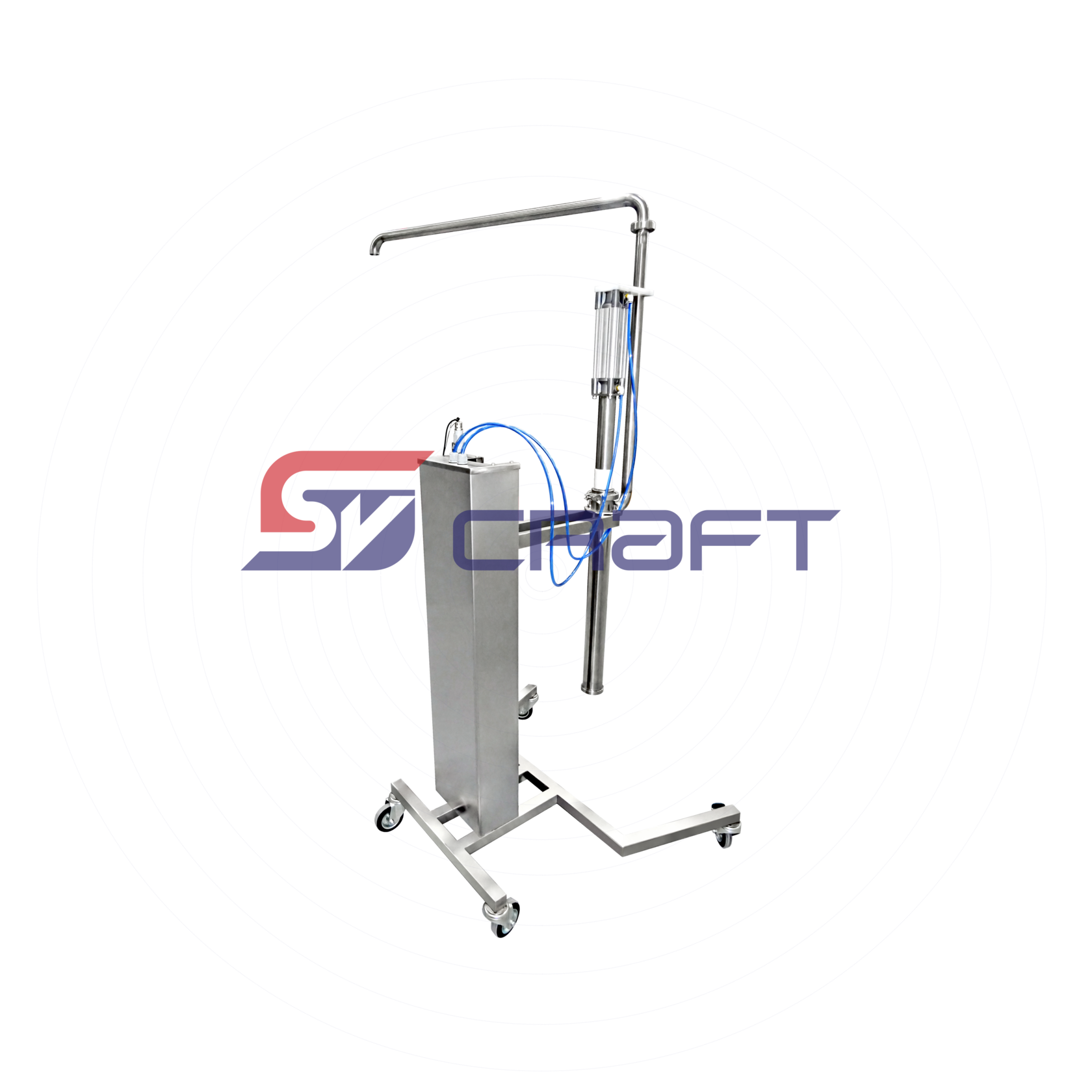

Cooling and drying

Cooling and drying

Refrigerating / drying tunnels are designed for cooling glazed and decorated confectionery products deposited on the tape. They can be supplied with a working area width from 300 mm to 1200 mm.

The cooling / drying tunnel can be installed after the "RoboExtruder" extrusion molding machine, the "RoboForm-Universal" jigging machine and the "RoboGlaze" glazing machine.

The tunnel drying passage type is used to remove moisture from products, while preserving their shape. The process of drying products consists of dewatering them through the circulation of warm air. As a result, it creates an obstacle to the development of harmful microorganisms, for which water is a very favorable habitat.

Tunnels can be equipped with either a conveyor belt or a grid. We produce equipment with separate cooling and drying functions, as well as combined cooling/drying tunnels.

The cooling / drying tunnel can be installed after the "RoboExtruder" extrusion molding machine, the "RoboForm-Universal" jigging machine and the "RoboGlaze" glazing machine.

The tunnel drying passage type is used to remove moisture from products, while preserving their shape. The process of drying products consists of dewatering them through the circulation of warm air. As a result, it creates an obstacle to the development of harmful microorganisms, for which water is a very favorable habitat.

Tunnels can be equipped with either a conveyor belt or a grid. We produce equipment with separate cooling and drying functions, as well as combined cooling/drying tunnels.

Refrigerating / drying tunnels are designed for cooling glazed and decorated confectionery products deposited on the tape. They can be supplied with a working area width from 300 mm to 1200 mm.

The cooling / drying tunnel can be installed after the "RoboExtruder" extrusion molding machine, the "RoboForm-Universal" jigging machine and the "RoboGlaze" glazing machine.

The tunnel drying passage type is used to remove moisture from products, while preserving their shape. The process of drying products consists of dewatering them through the circulation of warm air. As a result, it creates an obstacle to the development of harmful microorganisms, for which water is a very favorable habitat.

Tunnels can be equipped with either a conveyor belt or a grid. We produce equipment with separate cooling and drying functions, as well as combined cooling/drying tunnels.

The cooling / drying tunnel can be installed after the "RoboExtruder" extrusion molding machine, the "RoboForm-Universal" jigging machine and the "RoboGlaze" glazing machine.

The tunnel drying passage type is used to remove moisture from products, while preserving their shape. The process of drying products consists of dewatering them through the circulation of warm air. As a result, it creates an obstacle to the development of harmful microorganisms, for which water is a very favorable habitat.

Tunnels can be equipped with either a conveyor belt or a grid. We produce equipment with separate cooling and drying functions, as well as combined cooling/drying tunnels.