8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

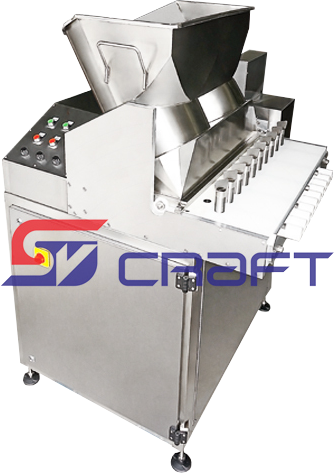

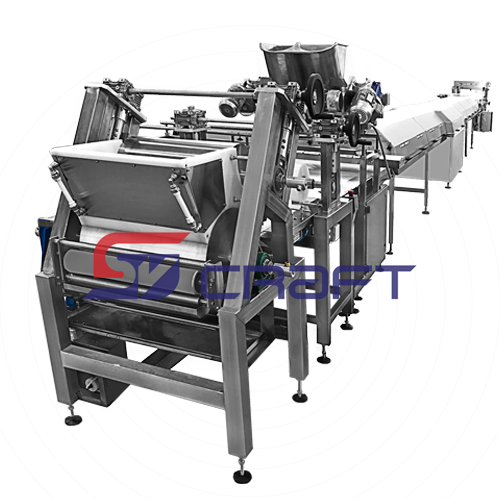

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

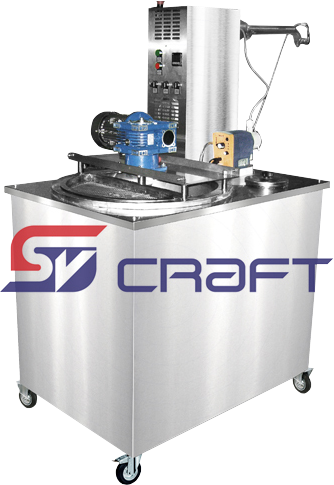

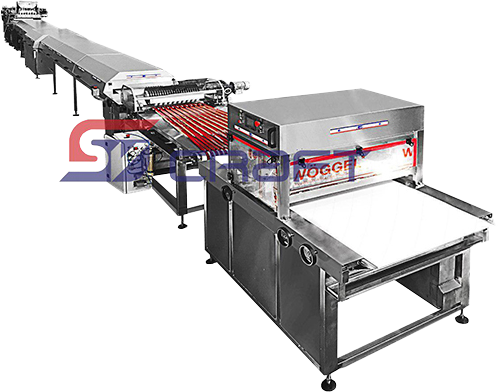

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

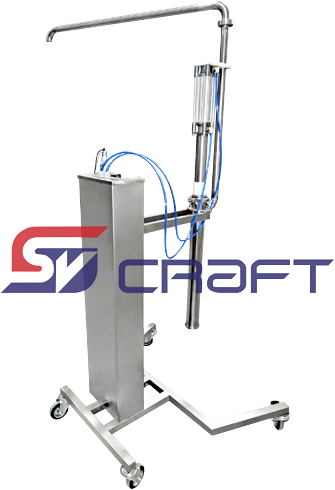

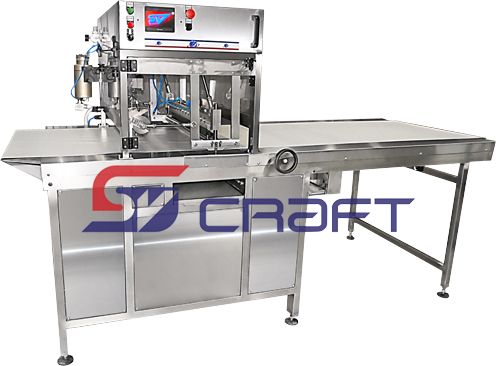

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

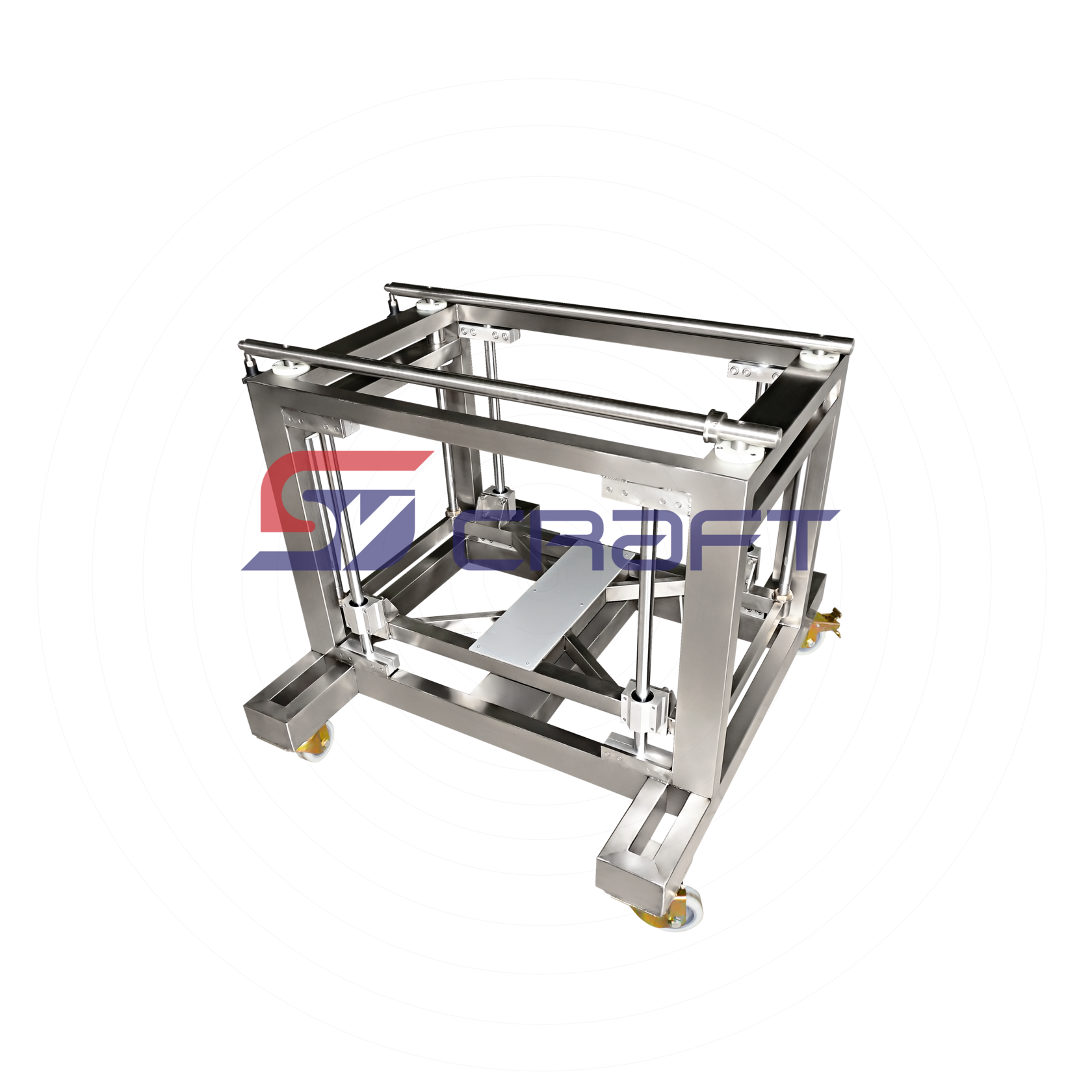

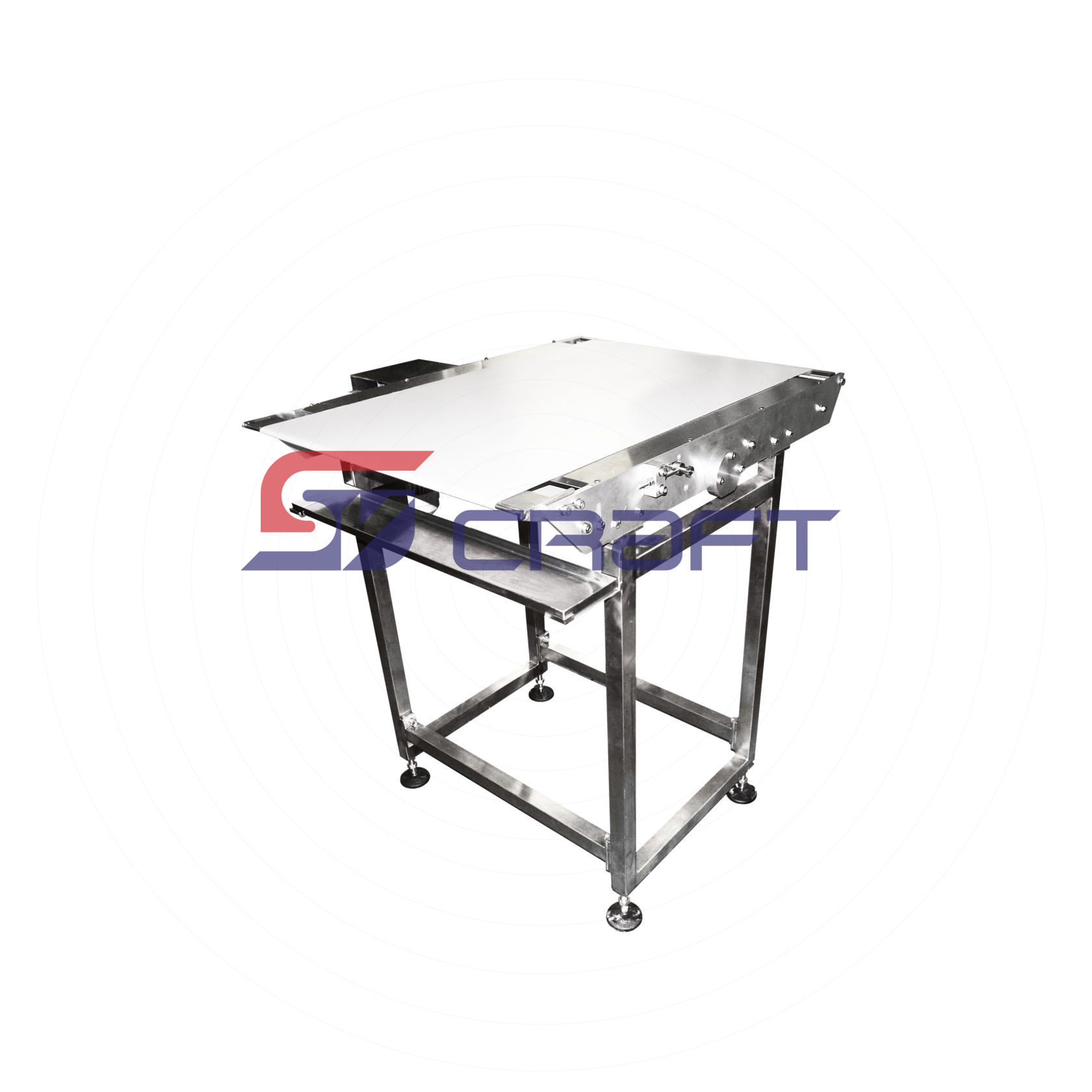

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

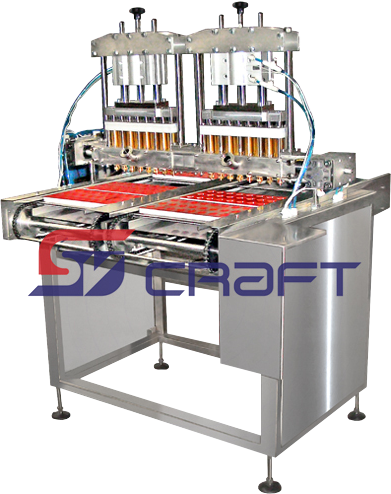

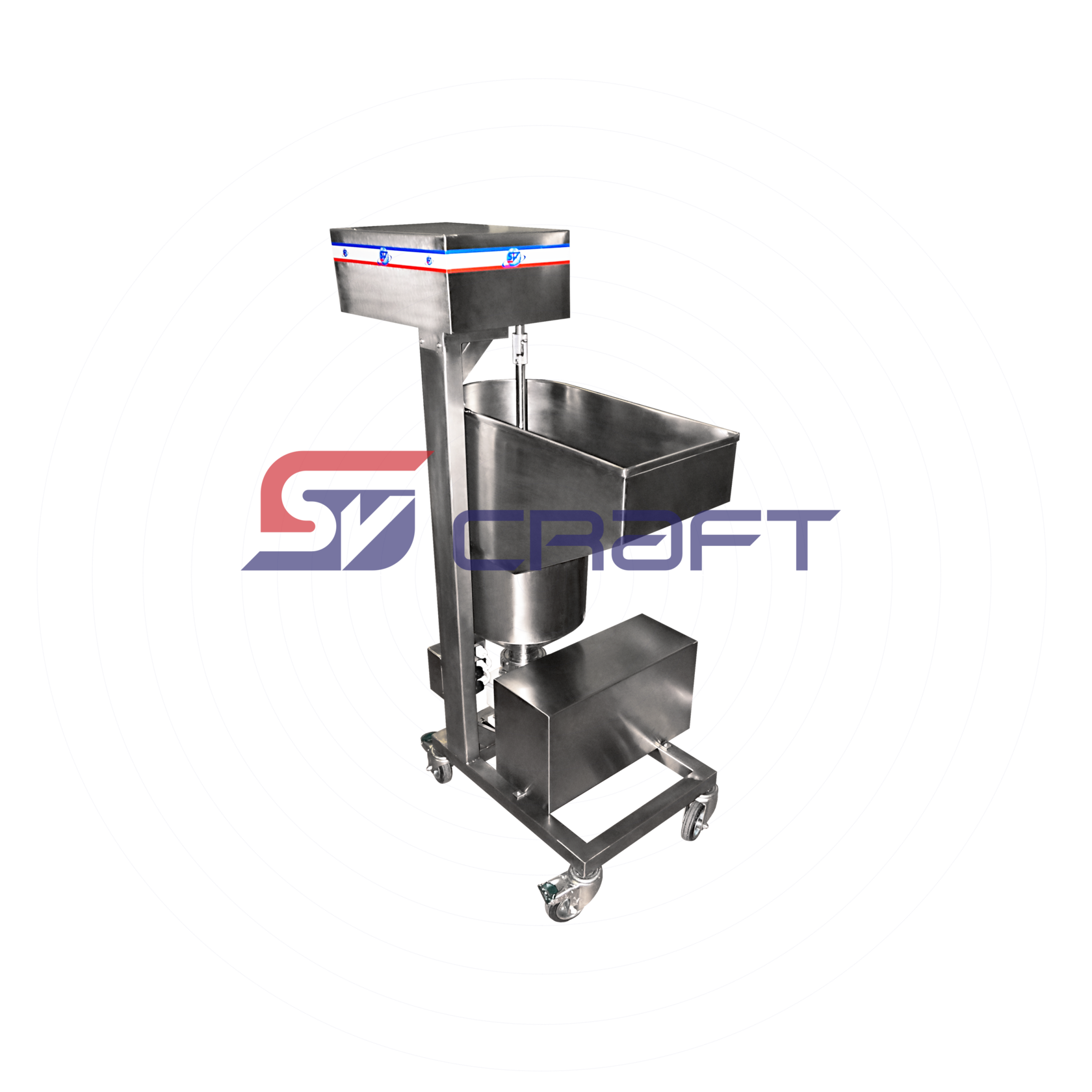

Filling machines

Filling machines

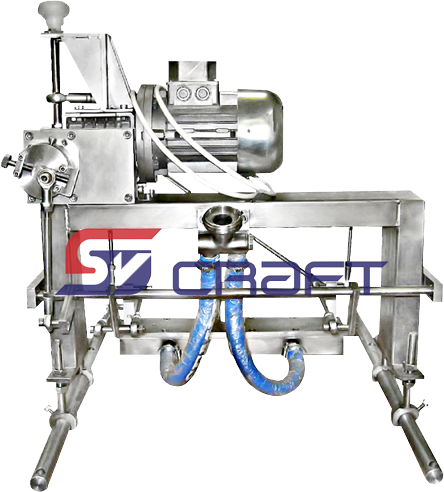

The equipment presented by the robofiller confectionery complex is distinguished by a unique technology for vertical filling of croissants, eclairs, cupcakes, profiteroles and many other finished products. Our filling machines allow you to increase the volume of products without taking up a lot of space in the room. In addition, the roll-gear feed system allows you to work with a wide range of weights in density – from whipped cream to boiled condensed milk and, importantly, will help you get rid of the different weight of the filling.

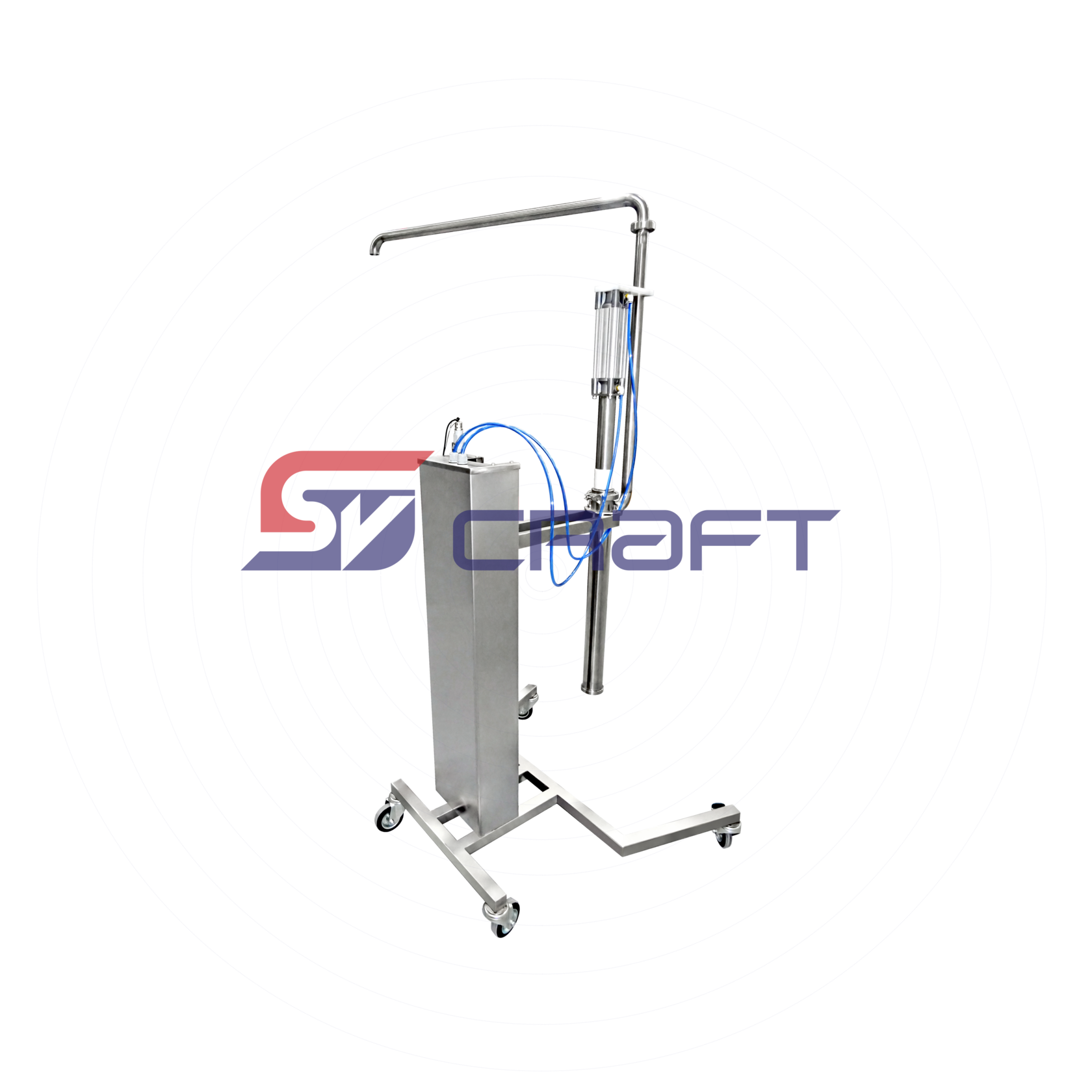

It can be wound inside the product by means of needles, as well as applied to the product from above or make a point jigging with the help of nozzles. The forms and types of needles and nozzles are agreed with the Customer at the stage of working out the technical task. For small-sized products, a new line of double-row filling machines has been developed and launched, which allows you to significantly increase productivity. In order to optimize the process and facilitate the work, we suggest using a pump for feeding confectionery masses with this equipment, which is designed to facilitate the loading of bins for jigging, extrusion, injection and casting machines. It is used for feeding liquid dough, confit, boiled condensed milk, etc.into the hopper of the jigging machine. The pump has Autonomous control and can be used with any jigging machine.

It can be wound inside the product by means of needles, as well as applied to the product from above or make a point jigging with the help of nozzles. The forms and types of needles and nozzles are agreed with the Customer at the stage of working out the technical task. For small-sized products, a new line of double-row filling machines has been developed and launched, which allows you to significantly increase productivity. In order to optimize the process and facilitate the work, we suggest using a pump for feeding confectionery masses with this equipment, which is designed to facilitate the loading of bins for jigging, extrusion, injection and casting machines. It is used for feeding liquid dough, confit, boiled condensed milk, etc.into the hopper of the jigging machine. The pump has Autonomous control and can be used with any jigging machine.

The equipment presented by the robofiller confectionery complex is distinguished by a unique technology for vertical filling of croissants, eclairs, cupcakes, profiteroles and many other finished products. Our filling machines allow you to increase the volume of products without taking up a lot of space in the room. In addition, the roll-gear feed system allows you to work with a wide range of weights in density – from whipped cream to boiled condensed milk and, importantly, will help you get rid of the different weight of the filling.

It can be wound inside the product by means of needles, as well as applied to the product from above or make a point jigging with the help of nozzles. The forms and types of needles and nozzles are agreed with the Customer at the stage of working out the technical task. For small-sized products, a new line of double-row filling machines has been developed and launched, which allows you to significantly increase productivity. In order to optimize the process and facilitate the work, we suggest using a pump for feeding confectionery masses with this equipment, which is designed to facilitate the loading of bins for jigging, extrusion, injection and casting machines. It is used for feeding liquid dough, confit, boiled condensed milk, etc.into the hopper of the jigging machine. The pump has Autonomous control and can be used with any jigging machine.

It can be wound inside the product by means of needles, as well as applied to the product from above or make a point jigging with the help of nozzles. The forms and types of needles and nozzles are agreed with the Customer at the stage of working out the technical task. For small-sized products, a new line of double-row filling machines has been developed and launched, which allows you to significantly increase productivity. In order to optimize the process and facilitate the work, we suggest using a pump for feeding confectionery masses with this equipment, which is designed to facilitate the loading of bins for jigging, extrusion, injection and casting machines. It is used for feeding liquid dough, confit, boiled condensed milk, etc.into the hopper of the jigging machine. The pump has Autonomous control and can be used with any jigging machine.