8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

Примечание

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

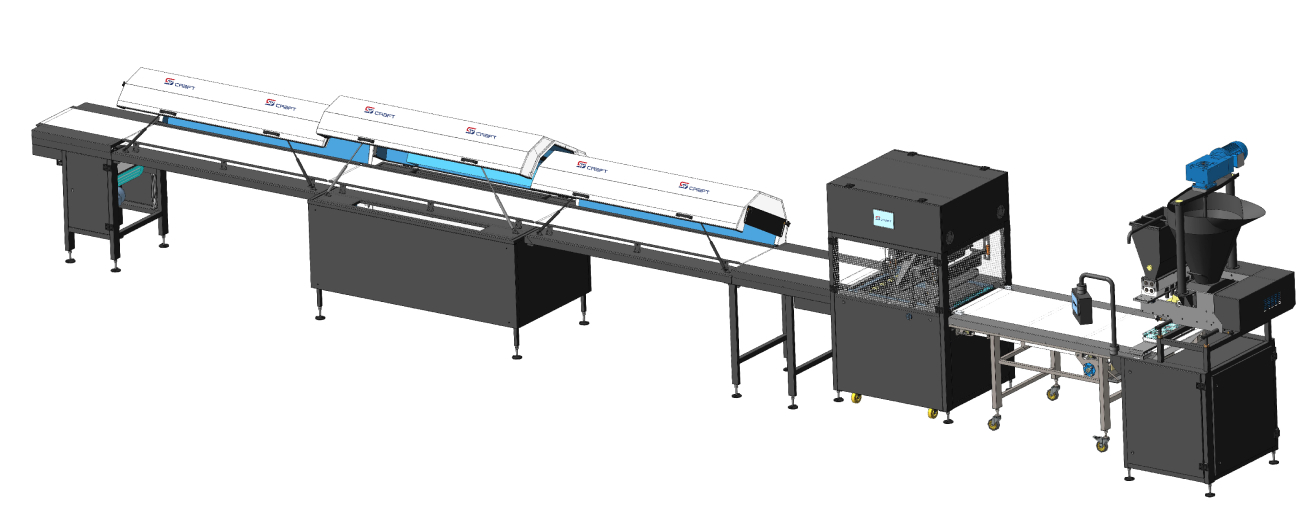

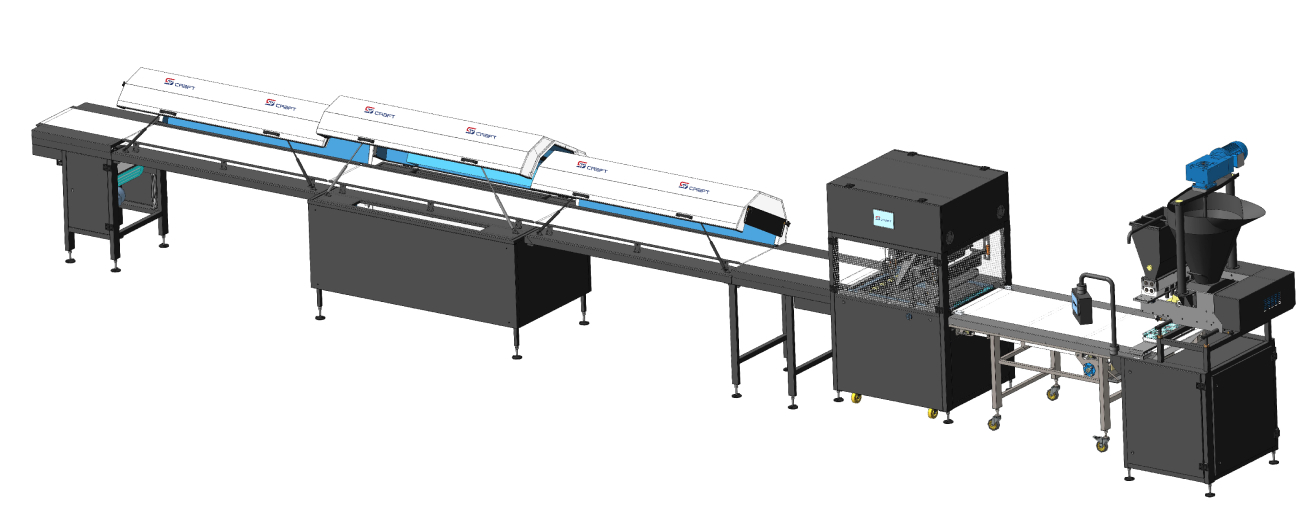

Curd cheese snacks line RoboCheeseLine

Curd cheese snacks line RoboCheeseLine

Price on request

Customized

Cheese production lines

SV craft company produces high-tech lines "RoboCheeseLine" for the production of curd glazed cheeses of various shapes, with or without filling, as well as combined glazed cheeses with cookies.

The mass of glazed cheese is usually from 40 to 50 grams

For the filling of chocolate glazed curd bars use such confectionery masses such as: boiled condensed milk, jellies, jams etc.

Buying a line of glazed cheeses allows you to establish the

production of this product together with the production of cottage cheese or other types of dairy products.

The high demand for glazed curd cheeses on the market fully recoups the costs in the shortest possible time.

The mass of glazed cheese is usually from 40 to 50 grams

For the filling of chocolate glazed curd bars use such confectionery masses such as: boiled condensed milk, jellies, jams etc.

Buying a line of glazed cheeses allows you to establish the

production of this product together with the production of cottage cheese or other types of dairy products.

The high demand for glazed curd cheeses on the market fully recoups the costs in the shortest possible time.

Price on request

Customized

Cheese production lines

SV craft company produces high-tech lines "RoboCheeseLine" for the production of curd glazed cheeses of various shapes, with or without filling, as well as combined glazed cheeses with cookies.

The mass of glazed cheese is usually from 40 to 50 grams

For the filling of chocolate glazed curd bars use such confectionery masses such as: boiled condensed milk, jellies, jams etc.

Buying a line of glazed cheeses allows you to establish the production of this product together with the production of cottage cheese or other types of dairy products.

The high demand for glazed curd cheeses on the market fully recoups the costs in the shortest possible time.

The mass of glazed cheese is usually from 40 to 50 grams

For the filling of chocolate glazed curd bars use such confectionery masses such as: boiled condensed milk, jellies, jams etc.

Buying a line of glazed cheeses allows you to establish the production of this product together with the production of cottage cheese or other types of dairy products.

The high demand for glazed curd cheeses on the market fully recoups the costs in the shortest possible time.

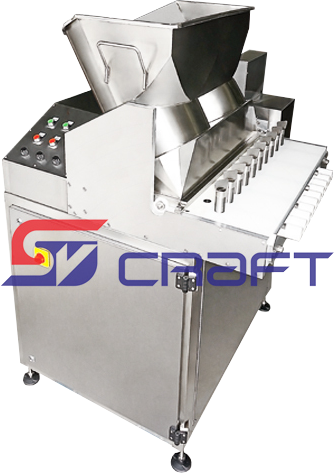

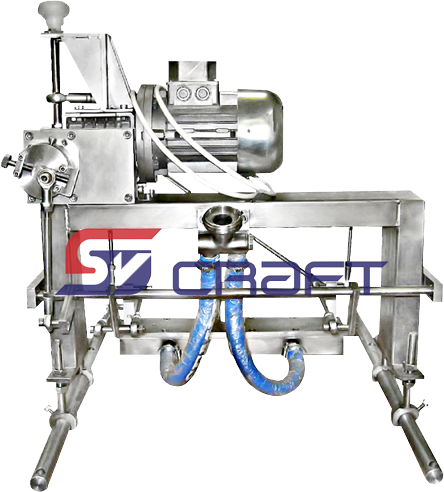

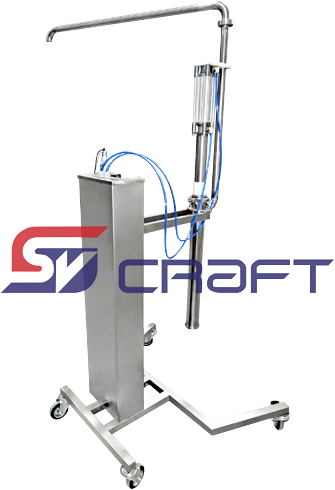

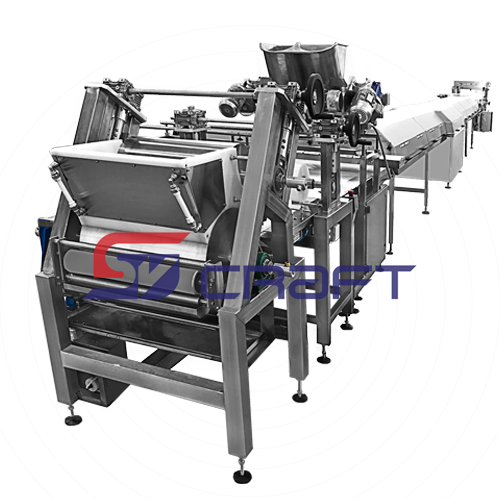

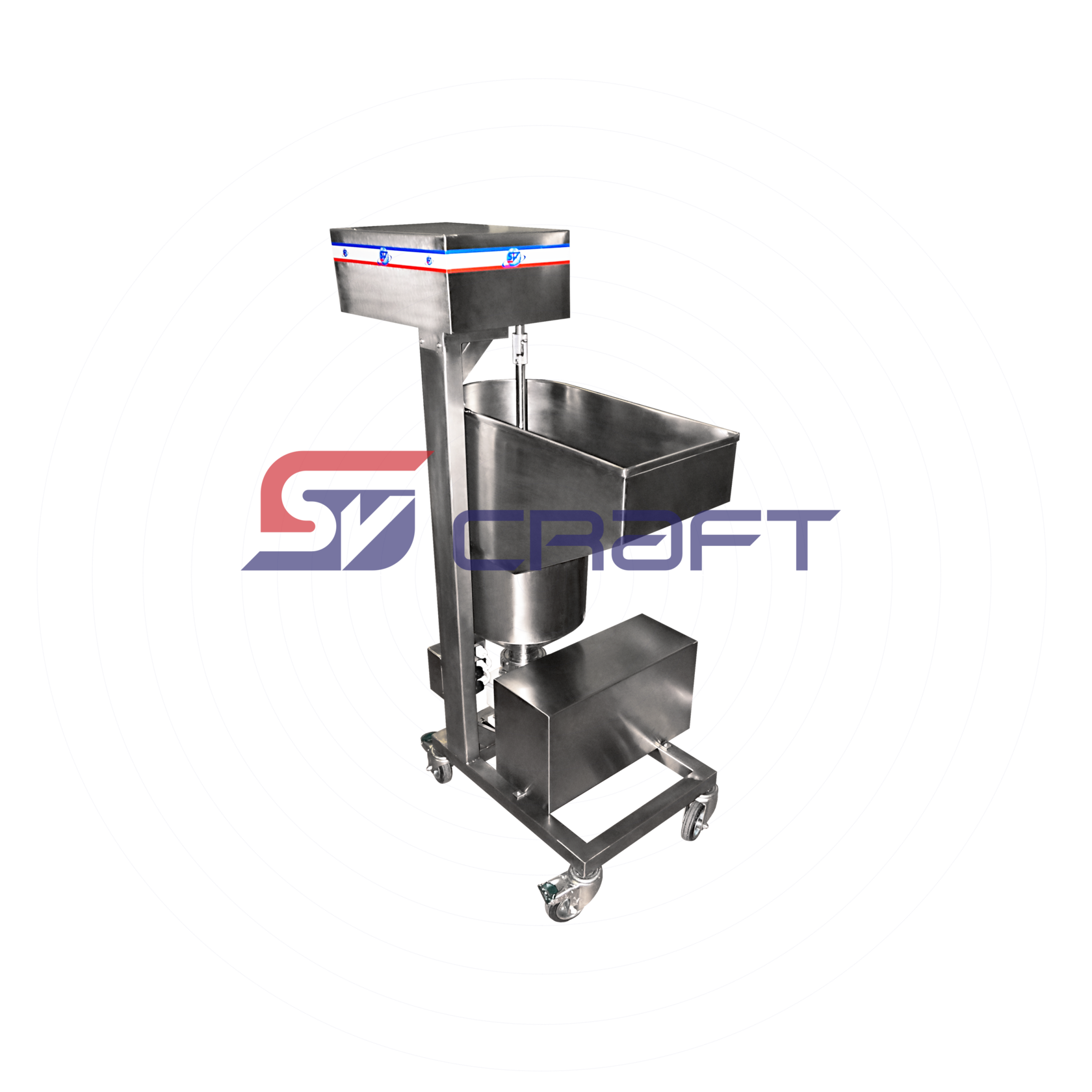

RoboExtruder - screw extruder with a sharp orifice intended for molding chocolate glazed curd bar with filling

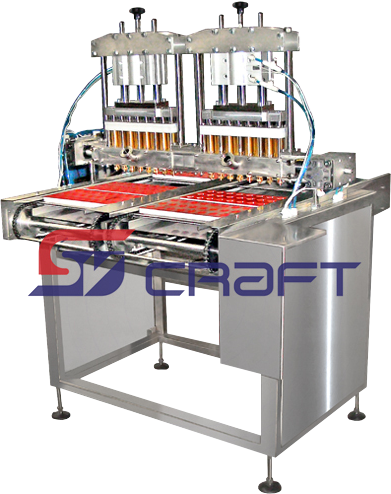

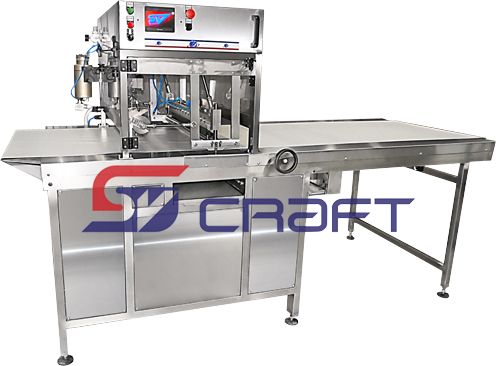

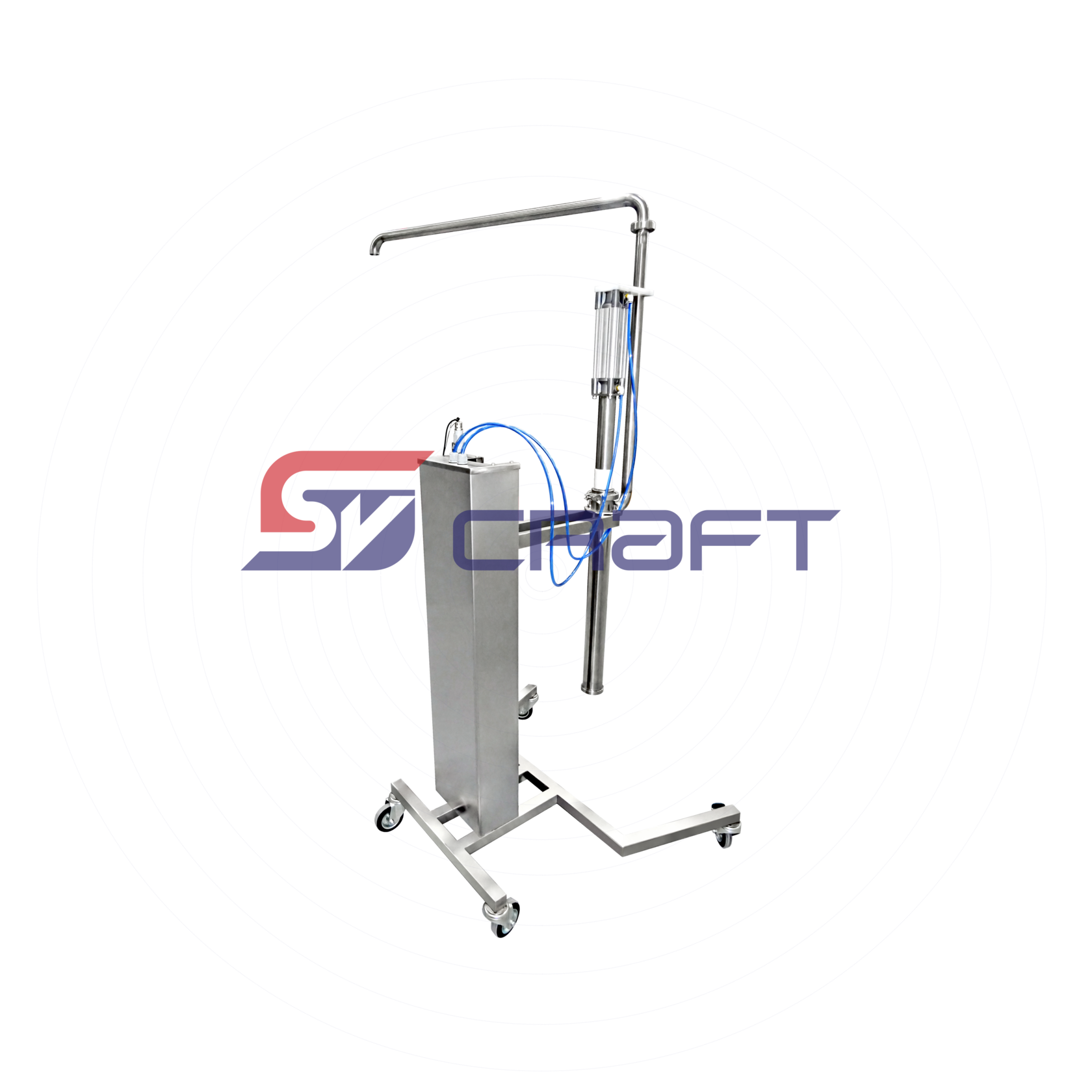

RoboGlaze is a Coating machine for curd cheese and confectionery products.

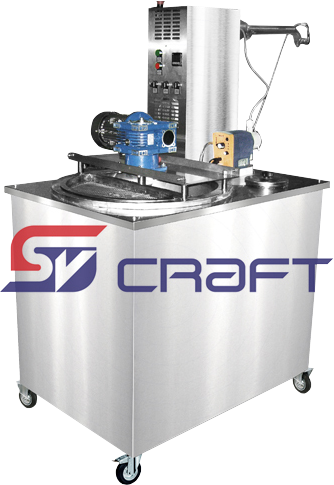

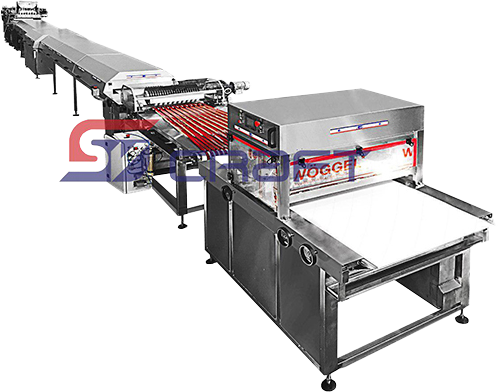

RoboCool-cooling tunnel for cooling cottage cheese and confectionery products

Оставьте заявку

Stages of production

The production process of glazed cheeses on the line is divided into 3 stages:

1

Molding

The curd mass is loaded into the receiving hopper of the molding machine, then loaded into a separate filling hopper. Then the curd mass and filling are fed through separate channels to the forming node from which the formed bundles of curd mass with the filling inside come out . Then the bundles are cut into separate billets by means of diaphragm cutting, at the same time the ends of the billet are rolled to prevent leakage of the filling.

2

Glazing

Next, the blanks fall into the glazing machine , where they are poured with glaze from above and from below, acquiring the appearance of glazed cheeses.

3

Cooling

Then the glazed cheeses are sent to the cooling tunnel, where the glazed cheeses are cooled to a predetermined temperature.

Products produced on this equipment

Products produced on this equipment

Video

Video

The line includes the following equipment:

The line includes the following equipment:

1

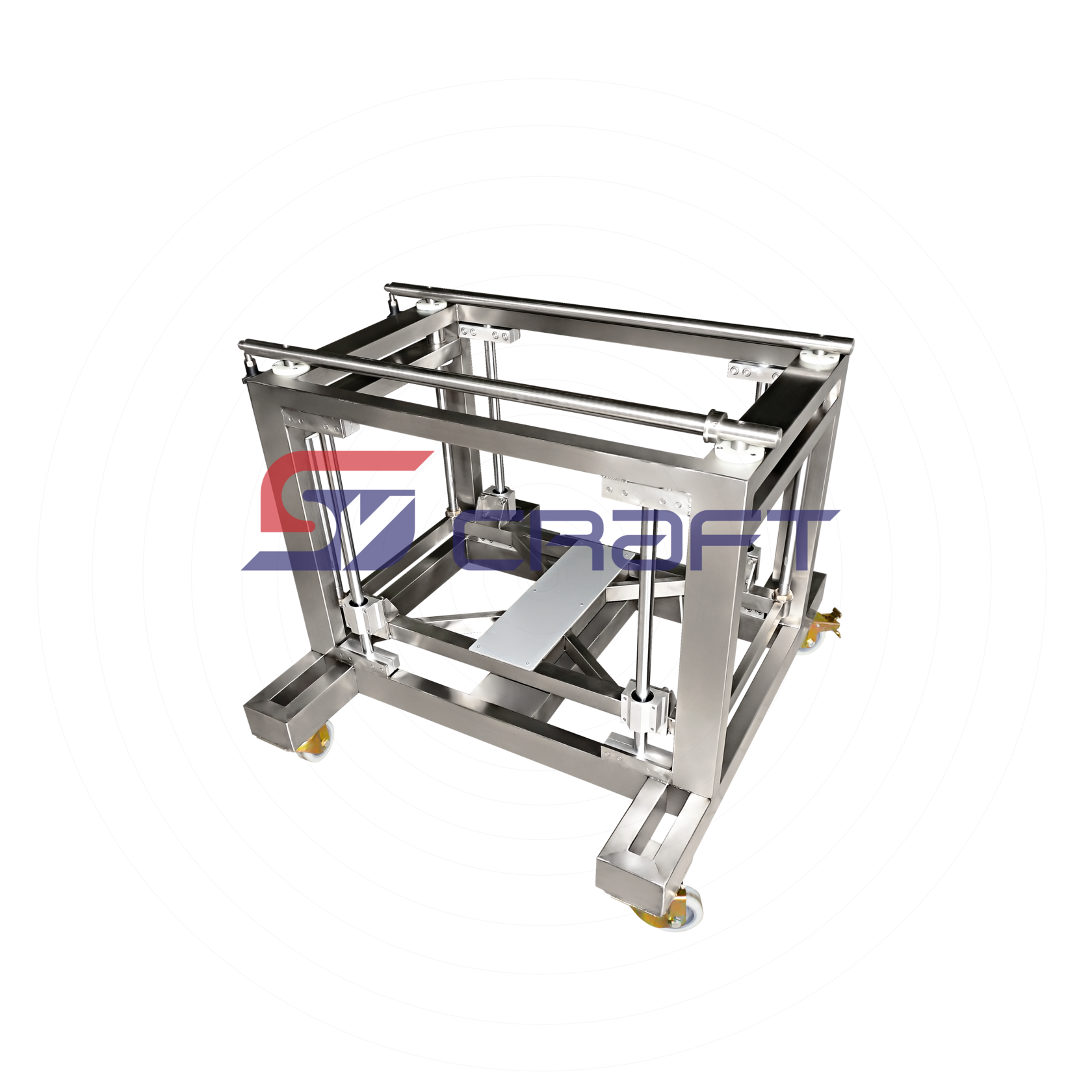

Screw extruder RoboExtruder

Frame for a single screw block with a width of 320 mm

Screw unit for feeding mass from 4 streams .

Unit for the installation roller-gear unit to supply the filling.

The pressure device.

Nozzle block.

Screw unit for feeding mass from 4 streams .

Unit for the installation roller-gear unit to supply the filling.

The pressure device.

Nozzle block.

3

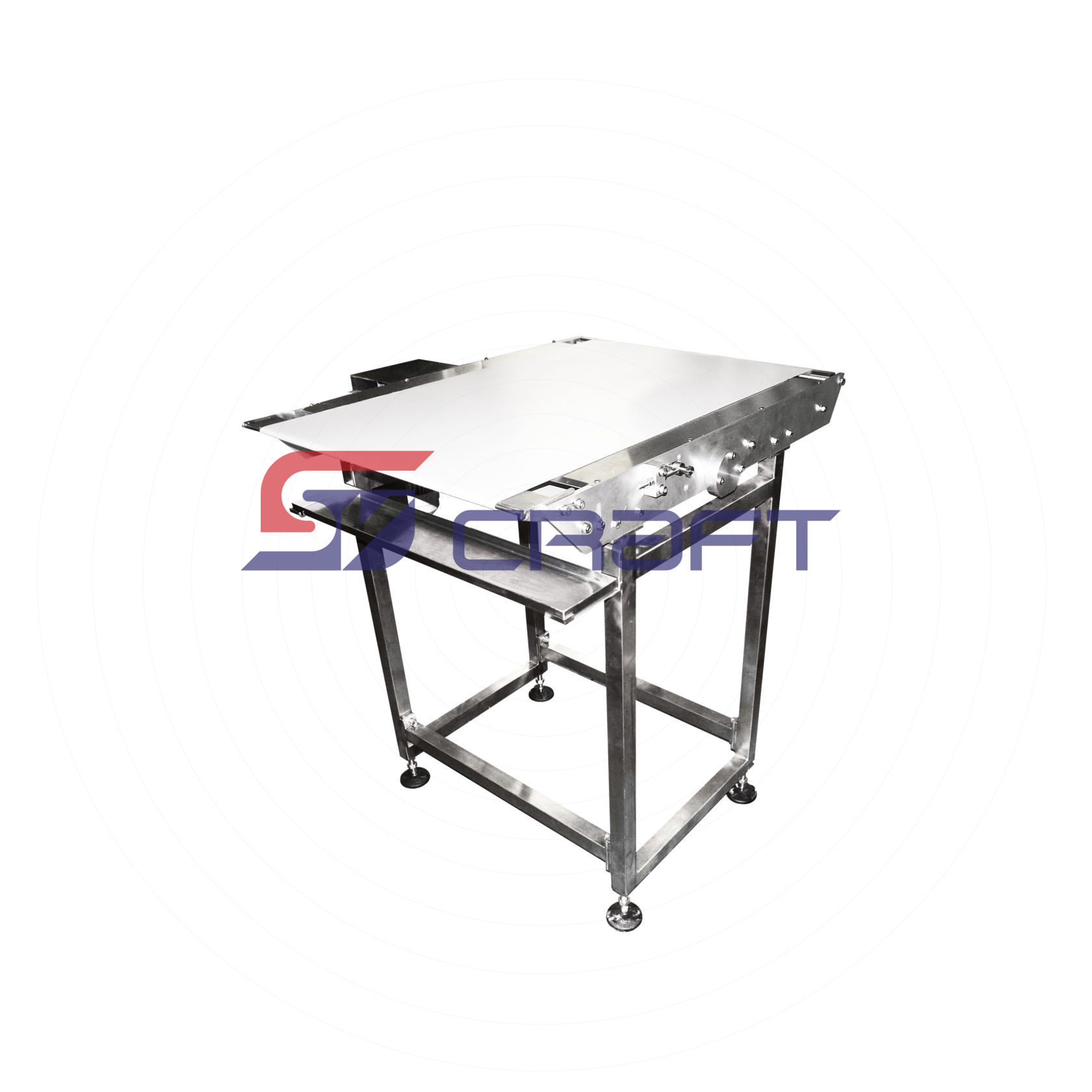

RoboCool cooling tunnel

The cooling tunnel is a flow- through refrigerating chamber, inside which a conveyor belt moves .

The entrance and exit tunnel sections have adjustable dampers.

Depending on the height

the dampers of the cooled products can be adjusted .

The input node performs the function of a normal conveyor. It receives products for further cooling.

When opening the tunnel covers, they are conveniently fixed with gas springs. In the cooling tunnel can

a cold table is installed to cool the bottom of the product.

The entrance and exit tunnel sections have adjustable dampers.

Depending on the height

the dampers of the cooled products can be adjusted .

The input node performs the function of a normal conveyor. It receives products for further cooling.

When opening the tunnel covers, they are conveniently fixed with gas springs. In the cooling tunnel can

a cold table is installed to cool the bottom of the product.

2

RoboGlaze glazing machine

The RoboGlaze glazing machine includes: a roll-out bath with a mesh conveyor, a drop-off roller, infrared heating of the surface of products, a pneumatic grid shaker, a blow-out, a PLC control system with a touch-screen display.

Glazing of confectionery products is carried out from the top, bottom or completely in one pass.

Additionally, the "RoboDecor" decorating device can be installed for drawing on the product, which can work in two coordinates.

The machine is also available in an exclusive configuration for covering products with two colors of glaze at the same time! In this case, the flow is divided in half along the course of the mesh conveyor, one half of the glazing machine covers the products with light, and the other with dark glaze.

Glazing of confectionery products is carried out from the top, bottom or completely in one pass.

Additionally, the "RoboDecor" decorating device can be installed for drawing on the product, which can work in two coordinates.

The machine is also available in an exclusive configuration for covering products with two colors of glaze at the same time! In this case, the flow is divided in half along the course of the mesh conveyor, one half of the glazing machine covers the products with light, and the other with dark glaze.

Additional RoboCheeseLine configuration

Additional RoboCheeseLine configuration

Cookie feeder

Stacker for cookies

RoboDekor Decorator

This equipment is intended for decorating confectionery products. "RoboDekor" decorators are available as stand-alone or built -in glazing machines.

Technical parameters

Technical parameters

Free consultation

Free consultation