8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

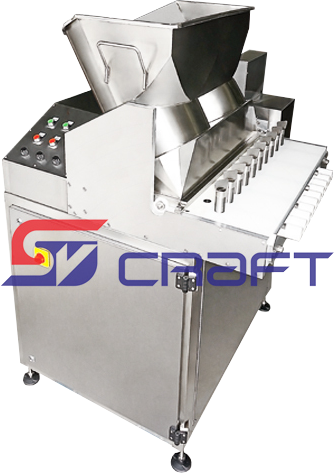

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

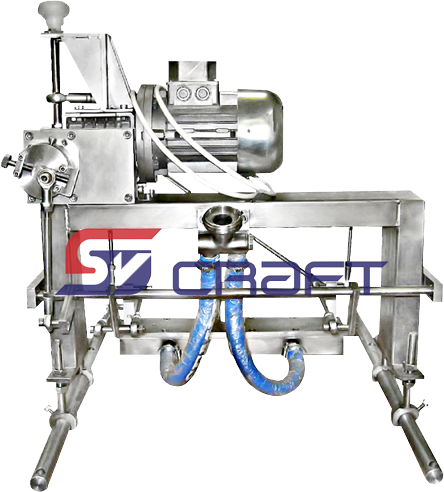

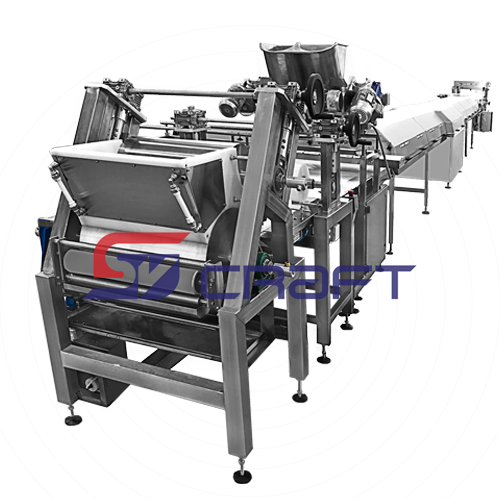

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

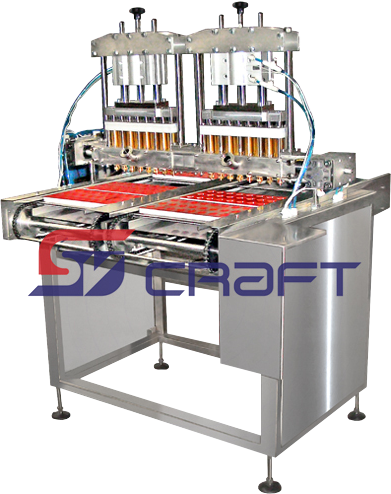

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

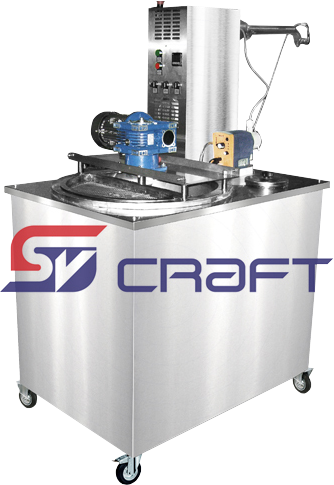

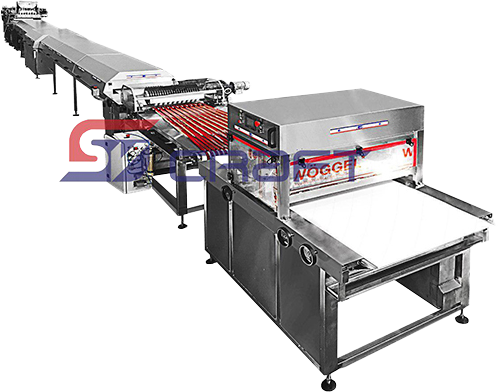

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

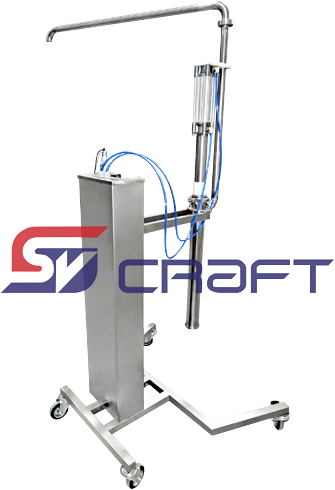

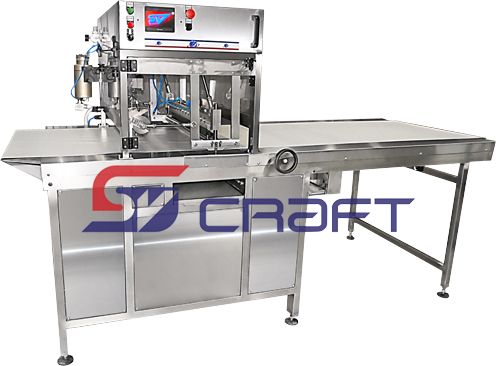

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

Примечание

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

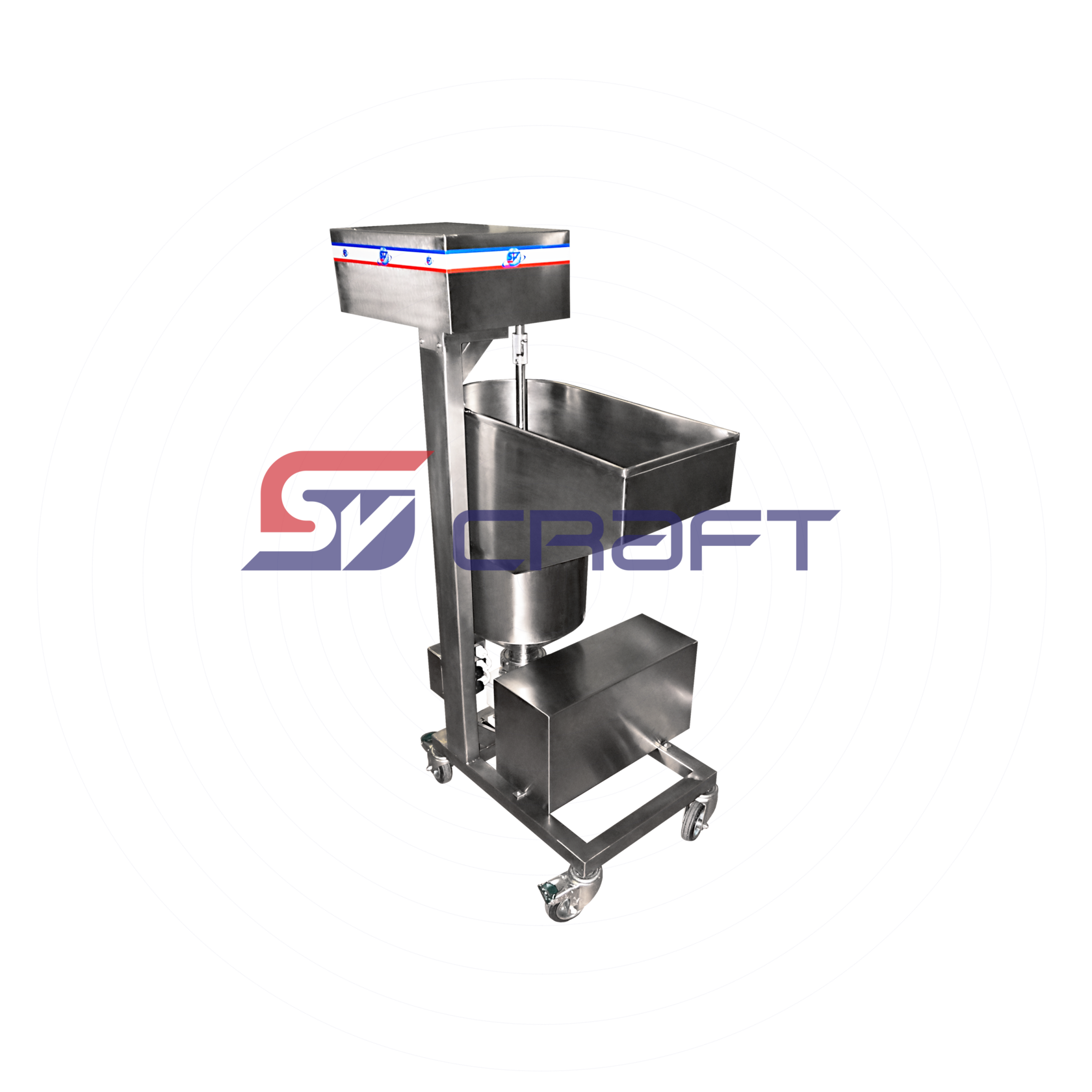

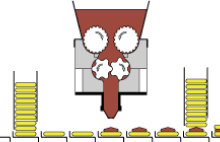

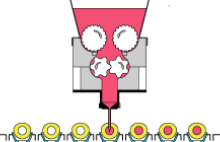

RoboFiller pastry filling machine

RoboFiller pastry filling machine

Наличие оборудования на складе.

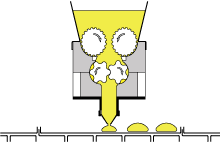

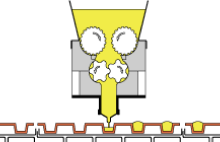

A single-hopper roller-gear machine is designed for filling pastry fillings.

The principle of roller -gear dough feeding is used by leading manufacturers of jigging machines . It allows you to significantly increase the productivity of the machine , weight calibration of products and expand the range of fillings used.

The principle of roller -gear dough feeding is used by leading manufacturers of jigging machines . It allows you to significantly increase the productivity of the machine , weight calibration of products and expand the range of fillings used.

Price on request

Customized

Single- bunker roller -gear machine " RoboFiller"

Additional options

Heating of bins

Slotted gate

Rewards

A single-hopper roller-gear machine is designed for filling pastry fillings.

The principle of roller -gear dough feeding is used by leading manufacturers of jigging machines . It allows you to significantly increase the productivity of the machine , weight calibration of products and expand the range of fillings used.

The principle of roller -gear dough feeding is used by leading manufacturers of jigging machines . It allows you to significantly increase the productivity of the machine , weight calibration of products and expand the range of fillings used.

Price on request

Customized

Single- bunker roller -gear machine " RoboFiller"

Additional options

Heating of bins

Slotted gate

Rewards

Оставьте заявку

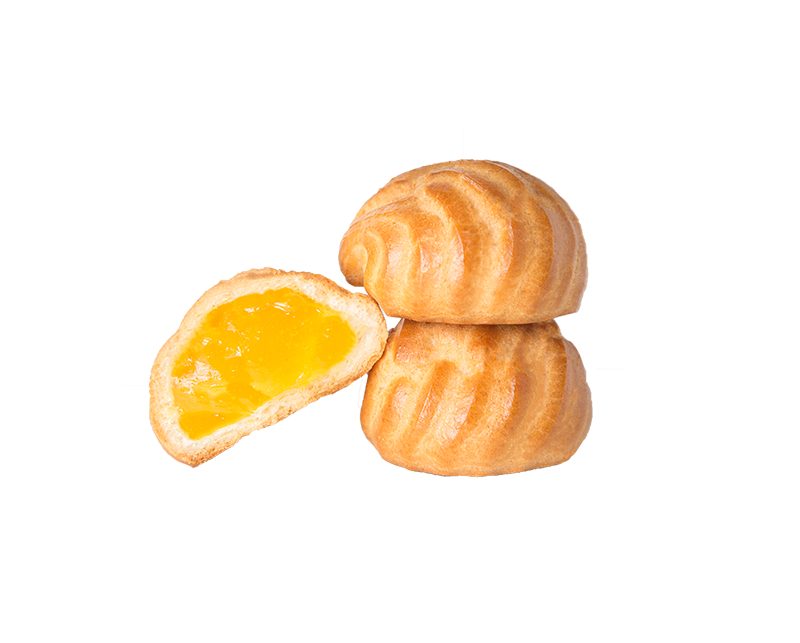

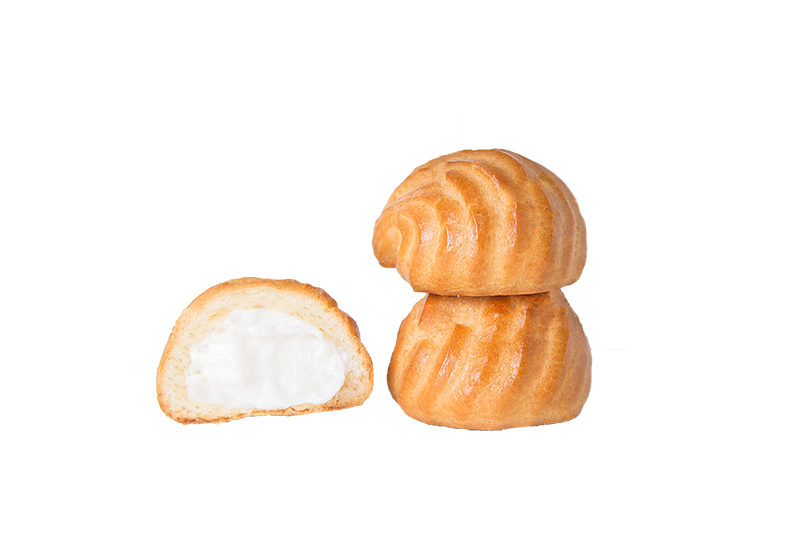

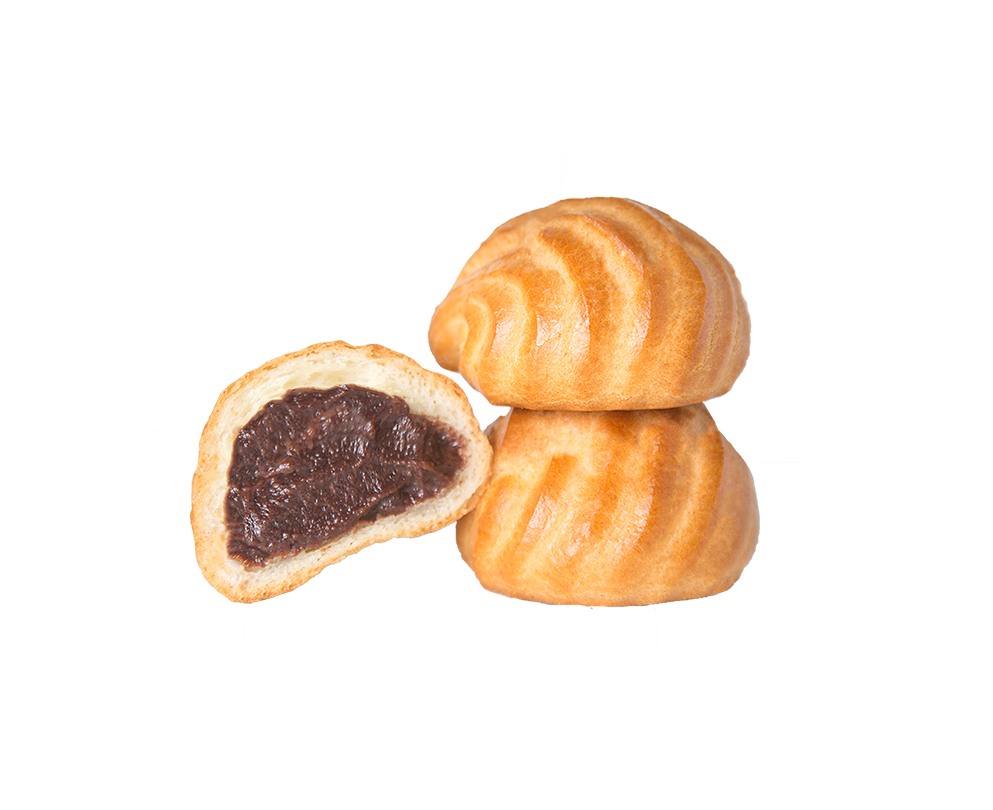

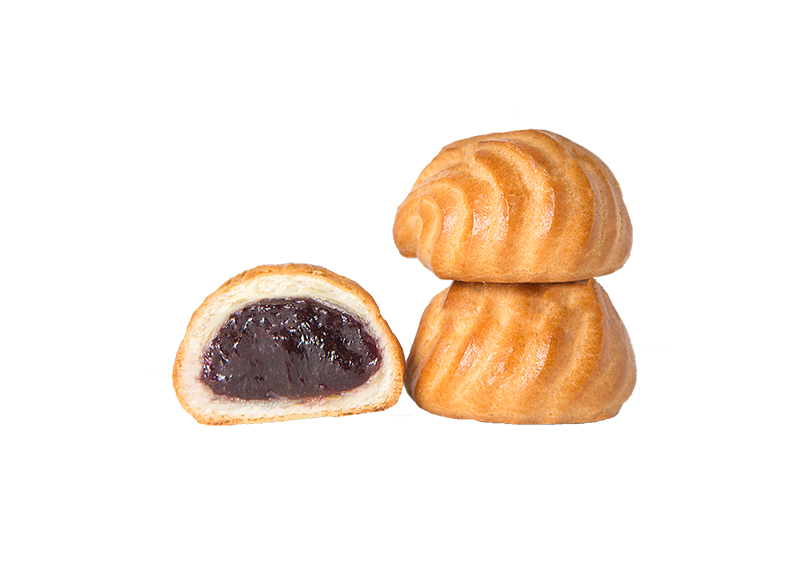

Products produced on this equipment

Products produced on this equipment

Video

Video

Basic features of RoboFiller

Basic features of RoboFiller

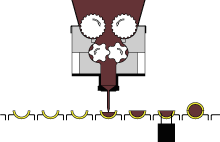

Machine with vertical movement of the jigging block. Conveyor with quick-release slats for different types of semi-finished products.

"RoboFiller" allows you to:

inject the filling into confectionery products (cupcakes, profiteroles, eclairs, croissants,muffins,rings);

fill pastry products with filling (cones, tubes, tartlets,cups);

For the filling, you can use confit, jam, chocolate paste, condensed milk (including boiled), pasty, jelly and curd masses, liquid marmalade.

"RoboFiller" allows you to:

inject the filling into confectionery products (cupcakes, profiteroles, eclairs, croissants,muffins,rings);

fill pastry products with filling (cones, tubes, tartlets,cups);

For the filling, you can use confit, jam, chocolate paste, condensed milk (including boiled), pasty, jelly and curd masses, liquid marmalade.

1

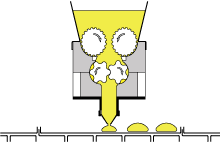

Depositing cookies (shortbread, oatmeal, almond, sponge), marshmallows-shells without filling, preparations of products from custard dough

2

Fudge and praline jigging

3

Casting of sponge layers, souffle masses ( such as pastille, poultry milk)

4

Filling the filling of the blank products from custard dough, waffle cones , waffle cups, tartlets

5

Creating sandwiches with different fillings

6

Production of complex confectionery products ( such as Fancy, Choco-pie, Bonjour)

Additional configuration

7

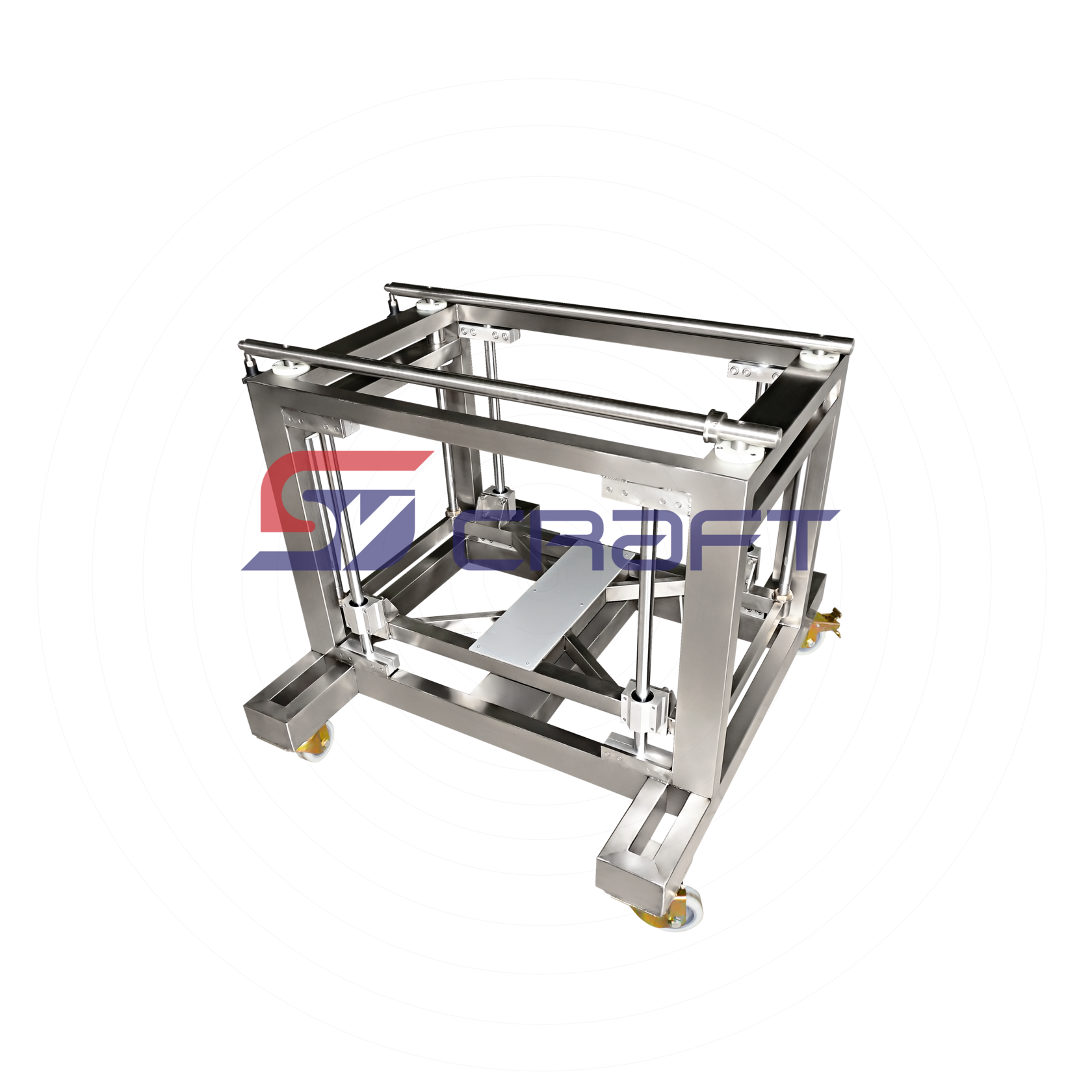

Configuration for depositing products - cookies, biscuit, oat, almond, and products made from choux pastry (éclairs, profiteroles), marshmallows, etc.

Machine with vertical movement of the jigging block. Conveyor with quick-release slats for different types of semi-finished products.

"RoboFiller" allows you to:

inject the filling into confectionery products (cupcakes, profiteroles, eclairs, croissants,muffins,rings);

fill pastry products with filling (cones, tubes, tartlets,cups);

For the filling, you can use confit, jam, chocolate paste, condensed milk (including boiled), pasty, jelly and curd masses, liquid marmalade.

"RoboFiller" allows you to:

inject the filling into confectionery products (cupcakes, profiteroles, eclairs, croissants,muffins,rings);

fill pastry products with filling (cones, tubes, tartlets,cups);

For the filling, you can use confit, jam, chocolate paste, condensed milk (including boiled), pasty, jelly and curd masses, liquid marmalade.

1

Depositing cookies (shortbread, oatmeal, almond, sponge), marshmallows-shells without filling, preparations of products from custard dough

2

Fudge and praline jigging

3

Casting of sponge layers, souffle masses ( such as pastille, poultry milk)

4

Filling the filling of the blank products from custard dough, waffle cones , waffle cups, tartlets

5

Creating sandwiches with different fillings

6

Production of complex confectionery products ( such as Fancy, Choco-pie, Bonjour)

Additional configuration

7

Configuration for depositing products - cookies, biscuit, oat, almond, and products made from choux pastry (éclairs, profiteroles), marshmallows, etc.

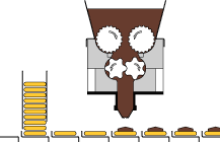

Installed: on the jigging block - nozzles for jigging, on the conveyor-pushing slats with a step equal to the length of the pan (400-600 mm), in the intervals - smooth slats. It is possible to fit round, oval and continuous products. The addition of the jigging unit with a rotary gate with a drive allows you to detach products with rotation

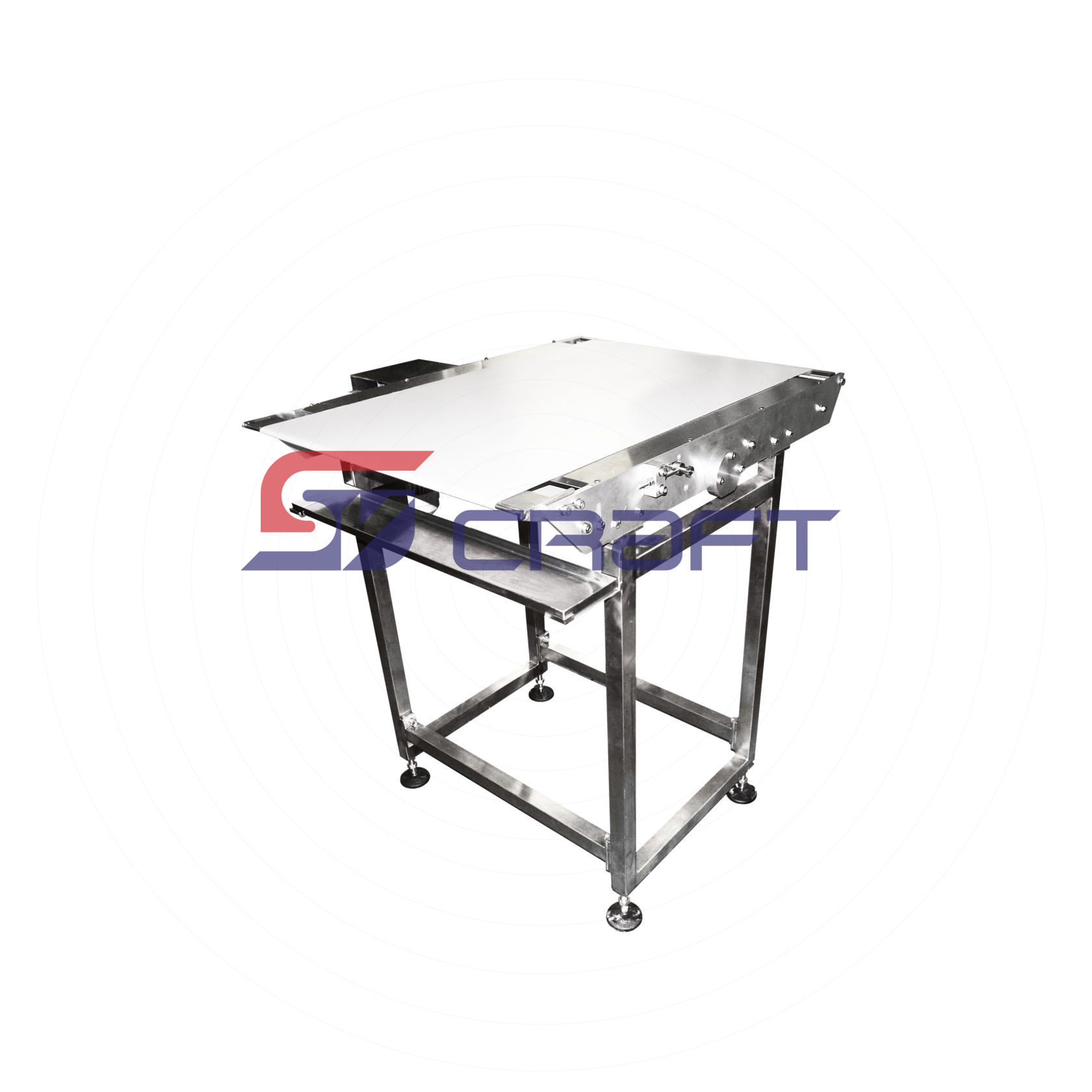

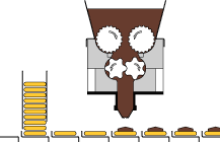

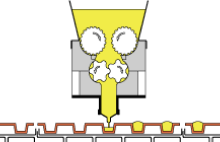

Configuration for casting cupcakes, etc. in silicone and metal baking molds : Installed: on the jigging block - nozzles for jigging cupcakes, on the conveyor-pushing slats with a step equal to the length of the mold (400-600 mm), in the intervals - smooth slats

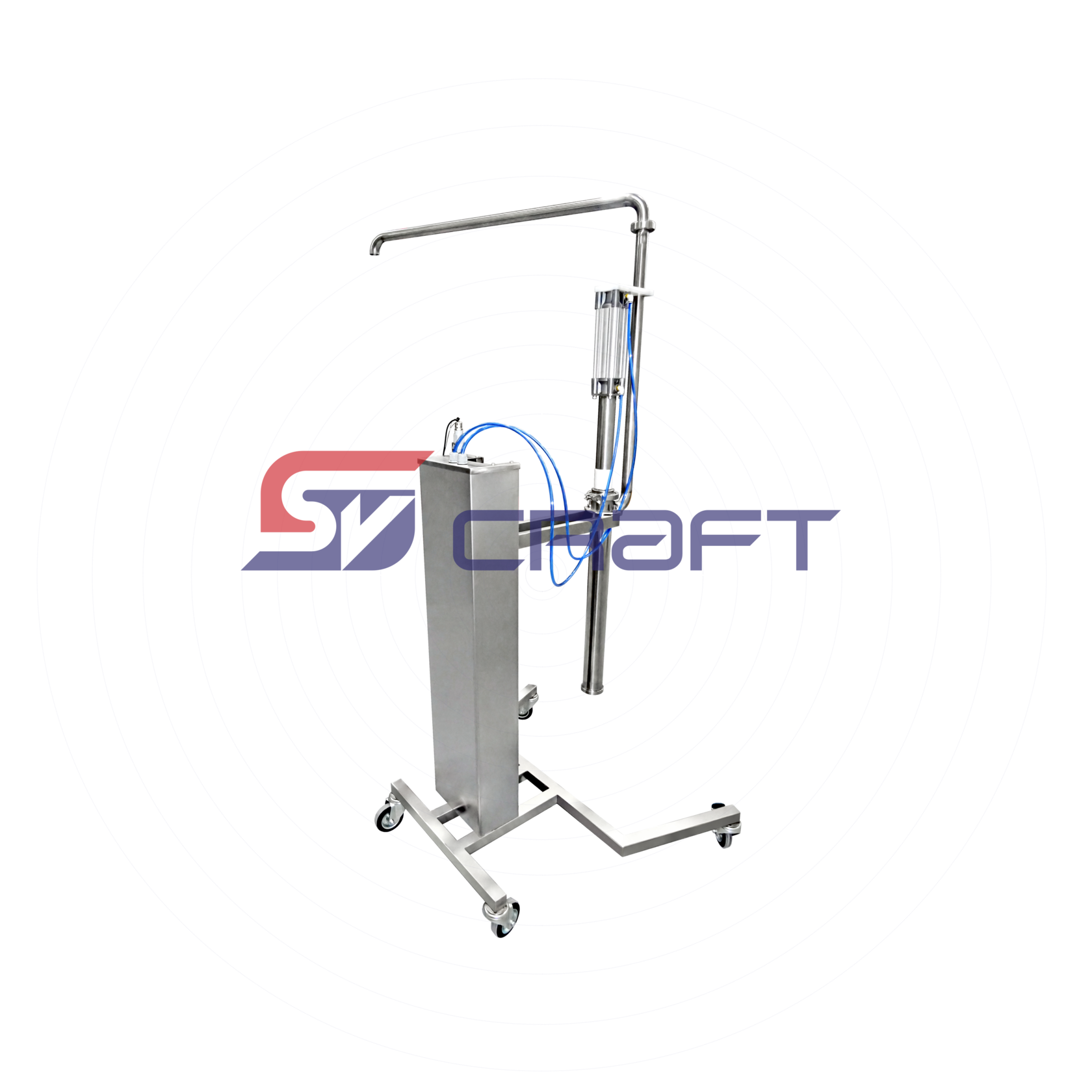

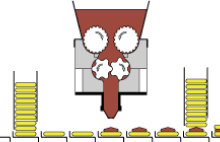

Configuration for filling injection: Installed: on the jigging block - needles for filling injection, on the conveyor-lamellas with cups for a specific workpiece.

Configuration for filling waffle cones, tartlets with filling: installed on the jigging block - nozzles for filling, on the conveyor-lamellas with cups for a specific workpiece.

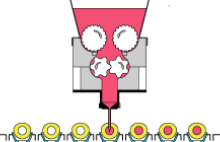

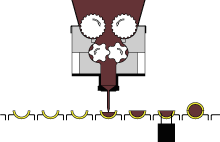

Configuration for applying the filling on top (products of the "Bonjour" type ): Installed: on the jigging block - nozzles for filling, on the conveyor - stacker for cookies, slats with cookie pushers.

Configuration for applying the filling between two cookies (products of the "Choco-pie" type ): Installed: on the jigging block - nozzles for the filling, on the conveyor - stackers for the upper and lower cookies, slats with cookie pushers.

Configuration for applying the filling between two shells (products of the "Nut" type ): Installed: on the jigging block - nozzles for filling, on the conveyor - a patented folding unit, slats for shells.

Installed: on the jigging block - nozzles for jigging, on the conveyor-pushing slats with a step equal to the length of the pan (400-600 mm), in the intervals - smooth slats. It is possible to fit round, oval and continuous products. The addition of a rotary gate with a drive to the jigging unit allows you to detach products with rotation

Configuration for casting cupcakes, etc. in silicone and metal baking molds : Installed: on the jigging block - nozzles for jigging cupcakes, on the conveyor-pushing slats with a step equal to the length of the mold (400-600 mm), in the intervals - smooth slats

Configuration for filling injection: Installed: on the jigging block - needles for filling injection, on the conveyor-lamellas with cups for a specific workpiece.

Configuration for filling waffle cones, tartlets with filling: installed on the jigging block - nozzles for filling, on the conveyor-lamellas with cups for a specific workpiece.

Configuration for applying the filling on top (products of the "Bonjour" type ): Installed: on the jigging block - nozzles for filling, on the conveyor - stacker for cookies, slats with cookie pushers.

Configuration for applying the filling between two cookies (products of the "Choco-pie" type ): Installed: on the jigging block - nozzles for the filling, on the conveyor - stackers for the upper and lower cookies, slats with cookie pushers.

Configuration for applying the filling between two shells (products of the "Nut" type ): Installed: on the jigging block - nozzles for filling, on the conveyor - a patented folding unit, slats for shells.

Technical parameters

Technical parameters