8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

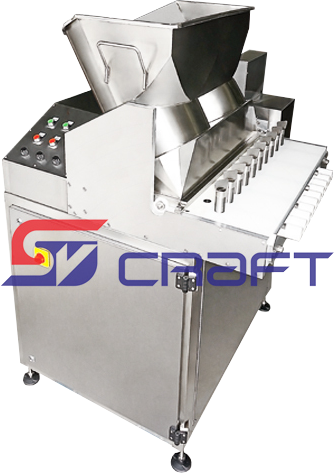

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

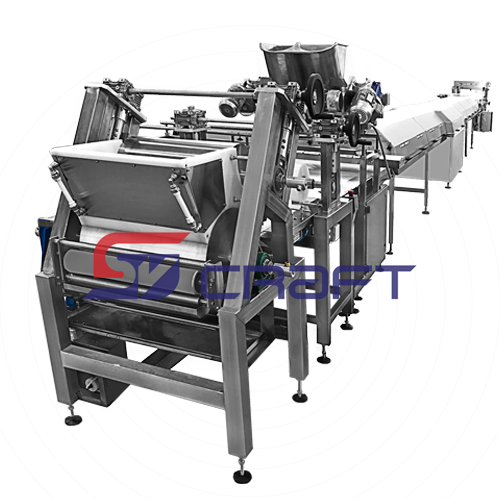

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

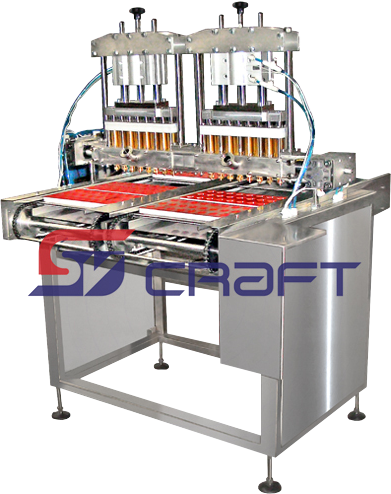

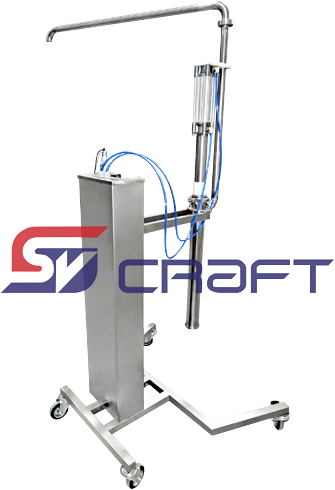

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

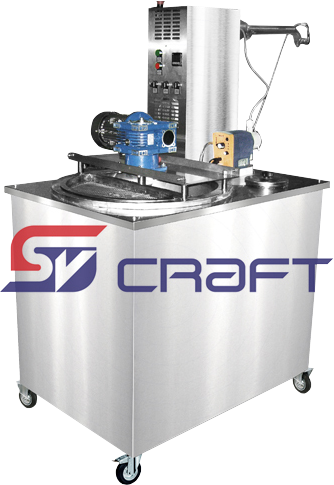

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

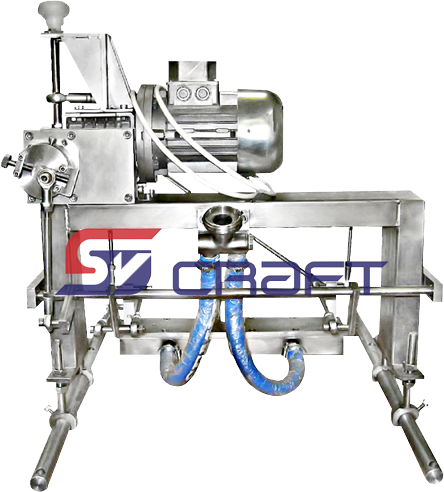

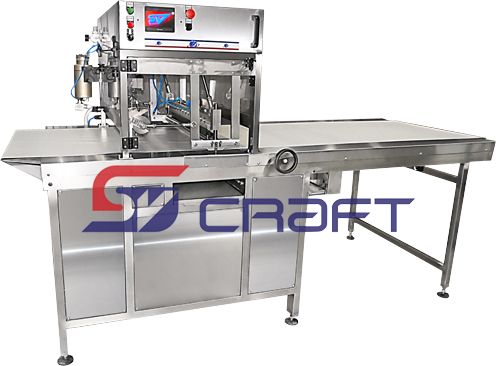

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

Примечание

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

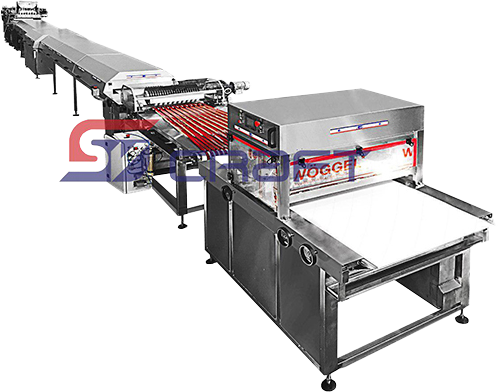

Refrigerating tunnel RoboCool

Refrigerating tunnel RoboCool

The cooling tunnel is a flow- through refrigerating chamber, inside which a conveyor belt moves .

The tunnel for cooling confectionery and food products is designed to automate the cooling process of products before packaging. The product enters the cooling chamber and as the tunnel passes, the glaze, chocolate, etc. on the confectionery is cooled under the influence of low temperature.

The cooling tunnel can be equipped with a conveyor belt, mesh or chain conveyor.

The tunnel for cooling confectionery and food products is designed to automate the cooling process of products before packaging. The product enters the cooling chamber and as the tunnel passes, the glaze, chocolate, etc. on the confectionery is cooled under the influence of low temperature.

The cooling tunnel can be equipped with a conveyor belt, mesh or chain conveyor.

Price on request

Customized

Refrigerating tunnel "RoboColol"

Additional equipment

Belt washing unit

The pallets are cooled (cold plate)

tape backing with a chiller

The pallets are cooled (cold plate)

tape backing with a chiller

Guarantee

12 months

12 months

The cooling tunnel is a flow- through refrigerating chamber, inside which a conveyor belt moves .

The tunnel for cooling confectionery and food products is designed to automate the cooling process of products before packaging. The product enters the cooling chamber and as the tunnel passes, the glaze, chocolate, etc. on the confectionery is cooled under the influence of low temperature.

The cooling tunnel can be equipped with a conveyor belt, mesh or chain conveyor.

The tunnel for cooling confectionery and food products is designed to automate the cooling process of products before packaging. The product enters the cooling chamber and as the tunnel passes, the glaze, chocolate, etc. on the confectionery is cooled under the influence of low temperature.

The cooling tunnel can be equipped with a conveyor belt, mesh or chain conveyor.

Price on request

Customized

Refrigerating tunnel "RoboColol"

Additional equipment

Belt washing unit

The pallets are cooled (cold plate)

tape backing with a chiller

The pallets are cooled (cold plate)

tape backing with a chiller

Guarantee

12 months

12 months

Оставьте заявку

Products produced on this equipment

Products produced on this equipment

Basic features of RoboCool

Basic features of RoboCool

Refrigeration units are installed depending on the temperature of the product at the inlet : up to 60 ° C - freon system; more than60 ° C - two- loop system water-freon. For better cooling of the bottom, additional cooling panels are installed with circulating cold water from an additional installed chiller

1

The conveyor system consists of:

- drive station with variable frequency drive, rubberized drive drum, belt cleaning or washing device, pneumatic belt equalizer, pneumatic belt tensioner and output knife extension regulator;

- tension station with pneumatic belt equalizer;

- high -quality, wear- resistant polyurethane or PVC tape

- drive station with variable frequency drive, rubberized drive drum, belt cleaning or washing device, pneumatic belt equalizer, pneumatic belt tensioner and output knife extension regulator;

- tension station with pneumatic belt equalizer;

- high -quality, wear- resistant polyurethane or PVC tape

2

Refrigerator made of U-shaped monolithic lids with a shell made of composite aluminum sheets and thermal insulation made of polyurethane foam. The covers are edged with a silicone seal, mounted on hinges and held open by pneumatic springs. The support trays of the tape are raised above the base to ensure cold air circulation under the tape and better cooling of the bottom of the product

3

A highly efficient refrigeration system located under the cooling chamber and does not take up extra space in the shop. The system can be equipped with a remote unit or a condenser , which reduces the noise level and does not increase the temperature in the shop

4

The cooling tunnel for confectionery products can be installed after the extrusion molding machine "RoboExtruder", the jigging machine "RoboForm-Universal" and the glazing machine " RoboGlaze»

5

The entrance and exit tunnel sections have adjustable dampers. Depending on the height of the cooled products, the dampers are raised or lowered. This reduces the loss of cold.

6

The input node performs the function of a normal conveyor. It receives products for further cooling

7

The belt tension unit includes the drive mechanism of the belt conveyor and the tension mechanism itself. The belt is driven by a gear motor through a rubber-coated drum. Belt tension is performed using two pneumatic cylinders.

8

At the output of the tape, a scraper is installed to clean the tape.

9

Both the input and the tension unit have special protection against belt misalignment during operation of the conveyor. To do this, they are equipped with special photo sensors that respond to the displacement of the tape. When the sensors are triggered, the roller along which the tape moves tilts , returning the tape to its original position. for this purpose, the belt tension system is equipped with pneumatic cylinders.

Refrigeration units are installed depending on the temperature of the product at the inlet : up to 60 ° C - freon system; more than60 ° C - two- loop system water-freon. For better cooling of the bottom, additional cooling panels are installed with circulating cold water from an additional installed chiller

1

The conveyor system consists of:

- drive station with variable frequency drive, rubberized drive drum, belt cleaning or washing device, pneumatic belt equalizer, pneumatic belt tensioner and output knife extension regulator;

- tension station with pneumatic belt equalizer;

- high -quality, wear- resistant polyurethane or PVC tape

- drive station with variable frequency drive, rubberized drive drum, belt cleaning or washing device, pneumatic belt equalizer, pneumatic belt tensioner and output knife extension regulator;

- tension station with pneumatic belt equalizer;

- high -quality, wear- resistant polyurethane or PVC tape

2

Refrigerator made of U-shaped monolithic lids with a shell made of composite aluminum sheets and thermal insulation made of polyurethane foam. The covers are edged with a silicone seal, mounted on hinges and held open by pneumatic springs. The support trays of the tape are raised above the base to ensure cold air circulation under the tape and better cooling of the bottom of the product

3

A highly efficient refrigeration system located under the cooling chamber and does not take up extra space in the shop. The system can be equipped with a remote unit or a condenser , which reduces the noise level and does not increase the temperature in the shop

4

The cooling tunnel for confectionery products can be installed after the extrusion molding machine "RoboExtruder", the jigging machine "RoboForm-Universal" and the glazing machine " RoboGlaze»

5

The entrance and exit tunnel sections have adjustable dampers. Depending on the height of the cooled products, the dampers are raised or lowered. This reduces the loss of cold.

6

The input node performs the function of a normal conveyor. It receives products for further cooling

7

The belt tension unit includes the drive mechanism of the belt conveyor and the tension mechanism itself. The belt is driven by a gear motor through a rubber-coated drum. Belt tension is performed using two pneumatic cylinders.

8

На выходе ленты установлен скребок для очистки ленты.

9

Both the input and the node of the tension, have a special protection against distortion of the tape during operation of the conveyor. To do this, they are equipped with special photo sensors that respond to the displacement of the tape. When the sensors are triggered, the roller along which the tape moves tilts , returning the tape to its original position. for this purpose, the belt tension system is equipped with pneumatic cylinders.

Technical parameters

Technical parameters

*Длина холодильного туннеля подбирается исходя из:

- стандартной длины секции 2м - скорости ленты

- количества времени нахождения изделия в туннеле. *Температура холодильной камеры определяется в процессе составления ТЗ

- стандартной длины секции 2м - скорости ленты

- количества времени нахождения изделия в туннеле. *Температура холодильной камеры определяется в процессе составления ТЗ