8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

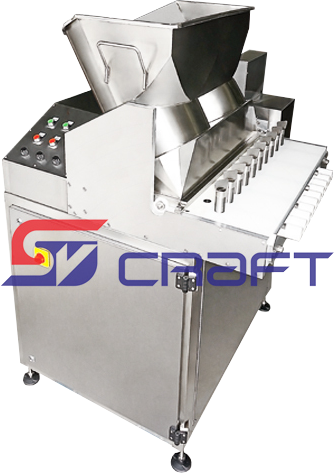

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

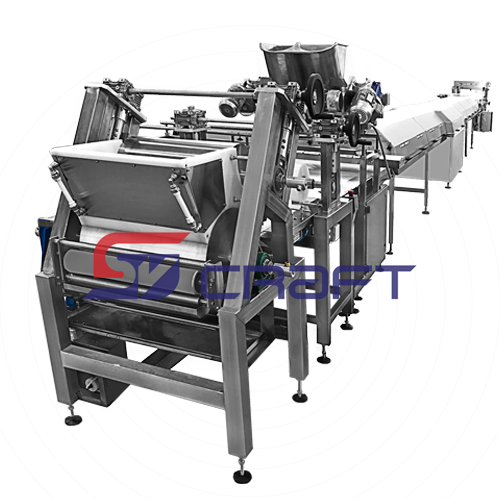

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

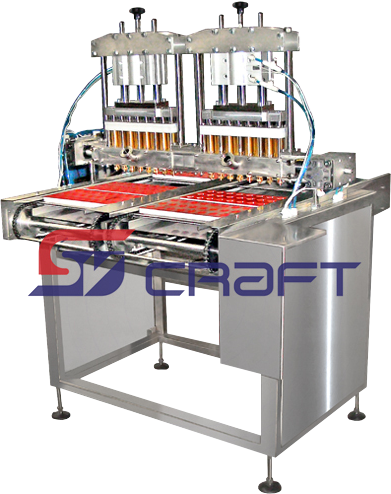

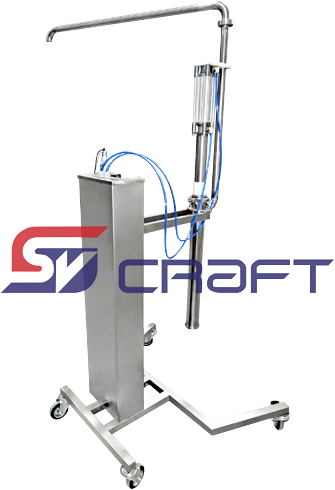

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

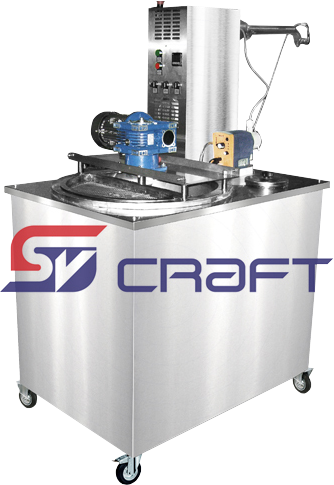

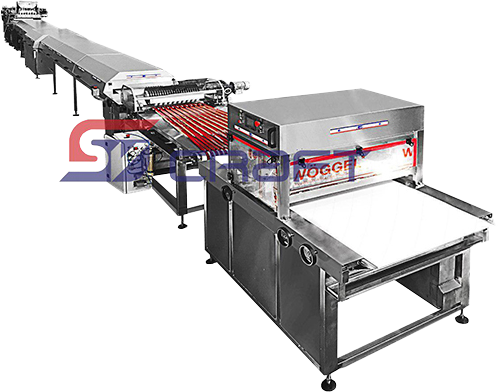

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

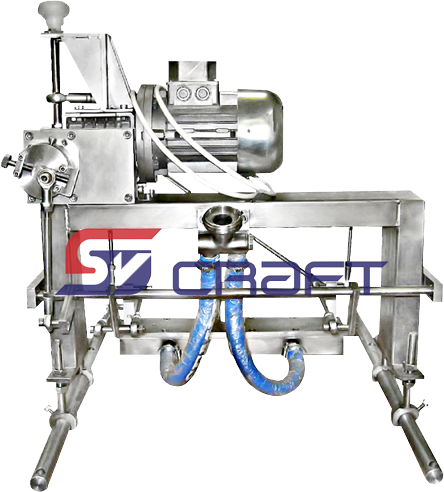

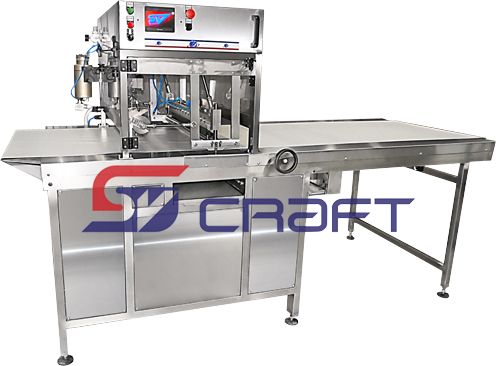

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

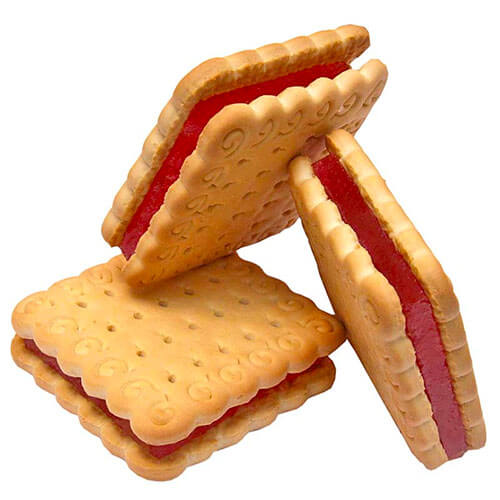

Line of production

complex confectionery products (Sandwich Line)

Line of production

complex confectionery products (Sandwich Line)

complex confectionery products (Sandwich Line)

The SV craft sandwich Line is designed for the production of sandwiches made from cookies and complex confectionery products.

As a base, you can use: sugar cookies, sponge cookies, shortbread cookies. Cookies made of sugar or shortbread dough are placed in stackers, then the cookies are positioned under the head for depositing the mass on the product.

The dosage is available in single, double or three-component filling to the cookies. For the filling used: various types of cream, boiled condensed milk, souffle, jam, marmalade, marshmallows, etc.

The next step is to lay the second cookie on top.

For marmalade casting, a marmalade — casting unit with several blocks for single, double or three-component filling is added. The equipment for the confectionery shop from SV craft allows you to produce products such as "Choco Pie", "Oreo".

As a base, you can use: sugar cookies, sponge cookies, shortbread cookies. Cookies made of sugar or shortbread dough are placed in stackers, then the cookies are positioned under the head for depositing the mass on the product.

The dosage is available in single, double or three-component filling to the cookies. For the filling used: various types of cream, boiled condensed milk, souffle, jam, marmalade, marshmallows, etc.

The next step is to lay the second cookie on top.

For marmalade casting, a marmalade — casting unit with several blocks for single, double or three-component filling is added. The equipment for the confectionery shop from SV craft allows you to produce products such as "Choco Pie", "Oreo".

Price on request

Customized

The SV craft sandwich Line is designed for the production of sandwiches made from cookies and complex confectionery products.

As a base, you can use: sugar cookies, sponge cookies, shortbread cookies. Cookies made of sugar or shortbread dough are placed in stackers, then the cookies are positioned under the head for depositing the mass on the product.

The dosage is available in single, double or three-component filling to the cookies. For the filling used: various types of cream, boiled condensed milk, souffle, jam, marmalade, marshmallows, etc.

The next step is to lay the second cookie on top.

For marmalade casting, a marmalade — casting unit with several blocks for single, double or three-component filling is added. The equipment for the confectionery shop from SV craft allows you to produce products such as "Choco Pie", "Oreo".

As a base, you can use: sugar cookies, sponge cookies, shortbread cookies. Cookies made of sugar or shortbread dough are placed in stackers, then the cookies are positioned under the head for depositing the mass on the product.

The dosage is available in single, double or three-component filling to the cookies. For the filling used: various types of cream, boiled condensed milk, souffle, jam, marmalade, marshmallows, etc.

The next step is to lay the second cookie on top.

For marmalade casting, a marmalade — casting unit with several blocks for single, double or three-component filling is added. The equipment for the confectionery shop from SV craft allows you to produce products such as "Choco Pie", "Oreo".

Price on request

Customized

Оставьте заявку

Products produced on this equipment

Products produced on this equipment

Video

Video

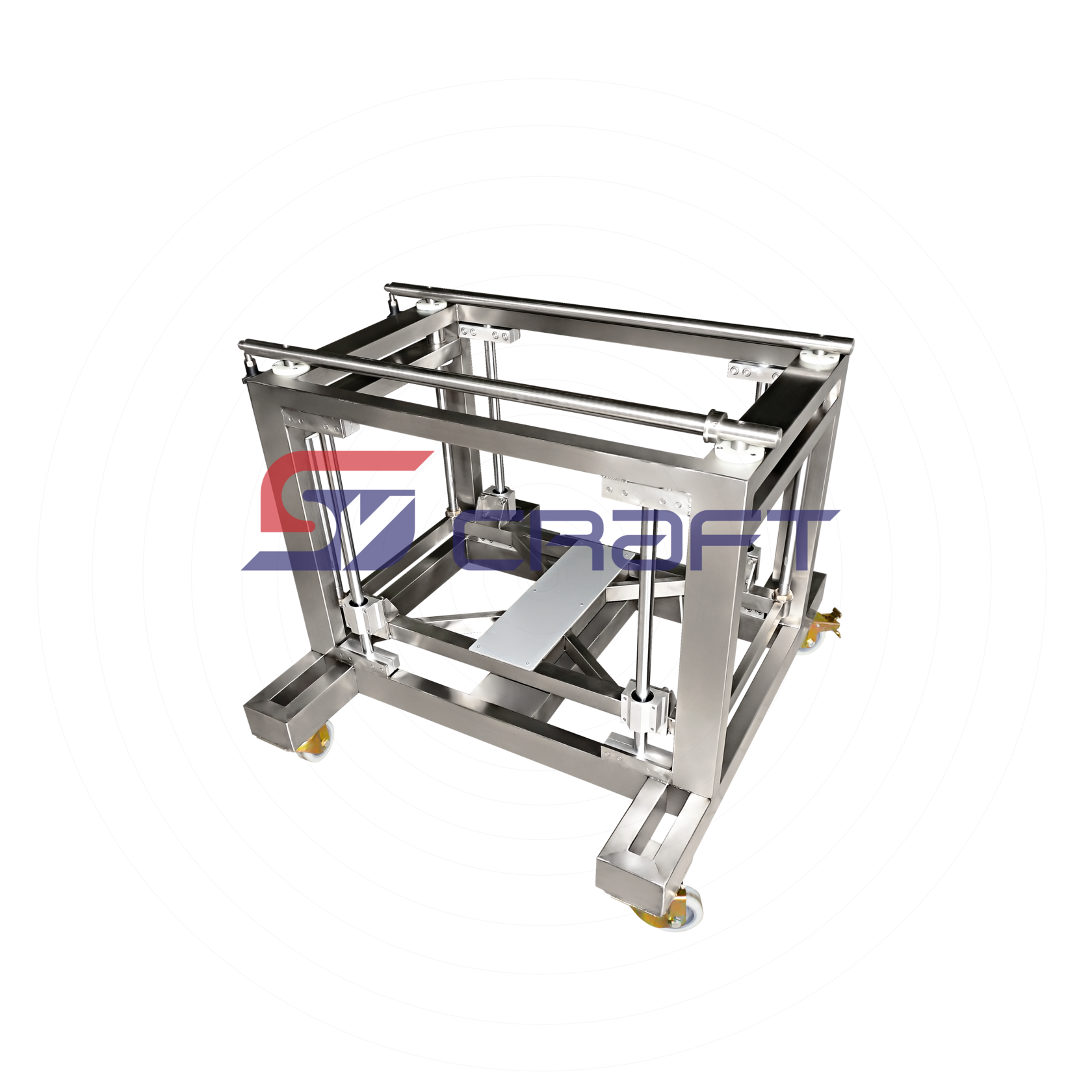

The configuration of the Sandwich line

The configuration of the Sandwich line

1

Type of transport

Belt or chain

2

Type of jigging unit

Piston, a roller-gear

3

Number and location of jigging units

4

Cookies stacker

5

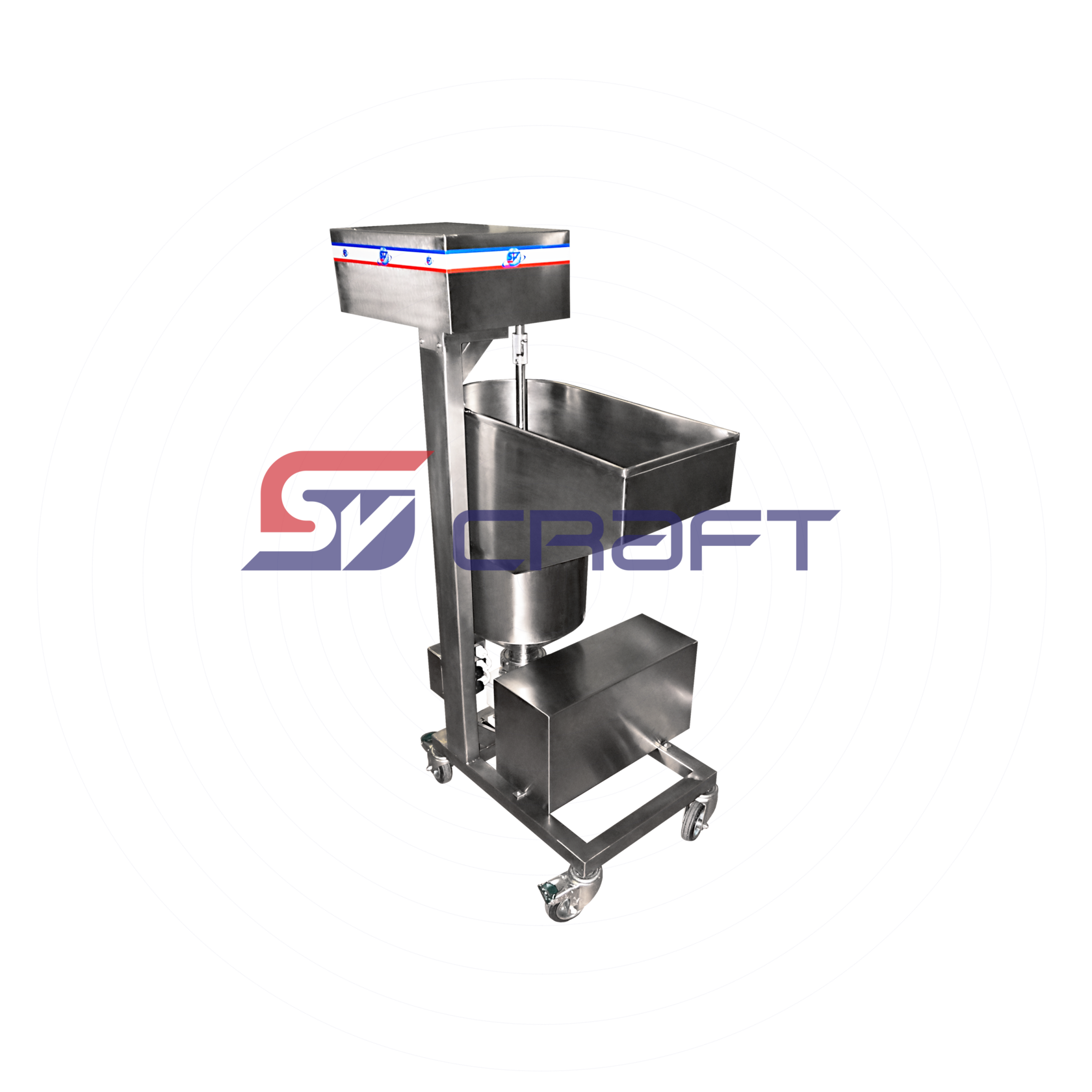

The power supply of marmalade

The marmalade supply unit consists of a marmalade tank with a pump, an acid tank with a metering pump, and a stirrer:

- the temperature of marmalade in the tank is maintained by a heated water jacket;

- supply of marmalade and acid to the agitator via separate heated pipelines;

- the amount of acid supplied is determined by the metering pump;

- volumetric dispenser.

- bunker heating.

- the temperature of marmalade in the tank is maintained by a heated water jacket;

- supply of marmalade and acid to the agitator via separate heated pipelines;

- the amount of acid supplied is determined by the metering pump;

- volumetric dispenser.

- bunker heating.

6

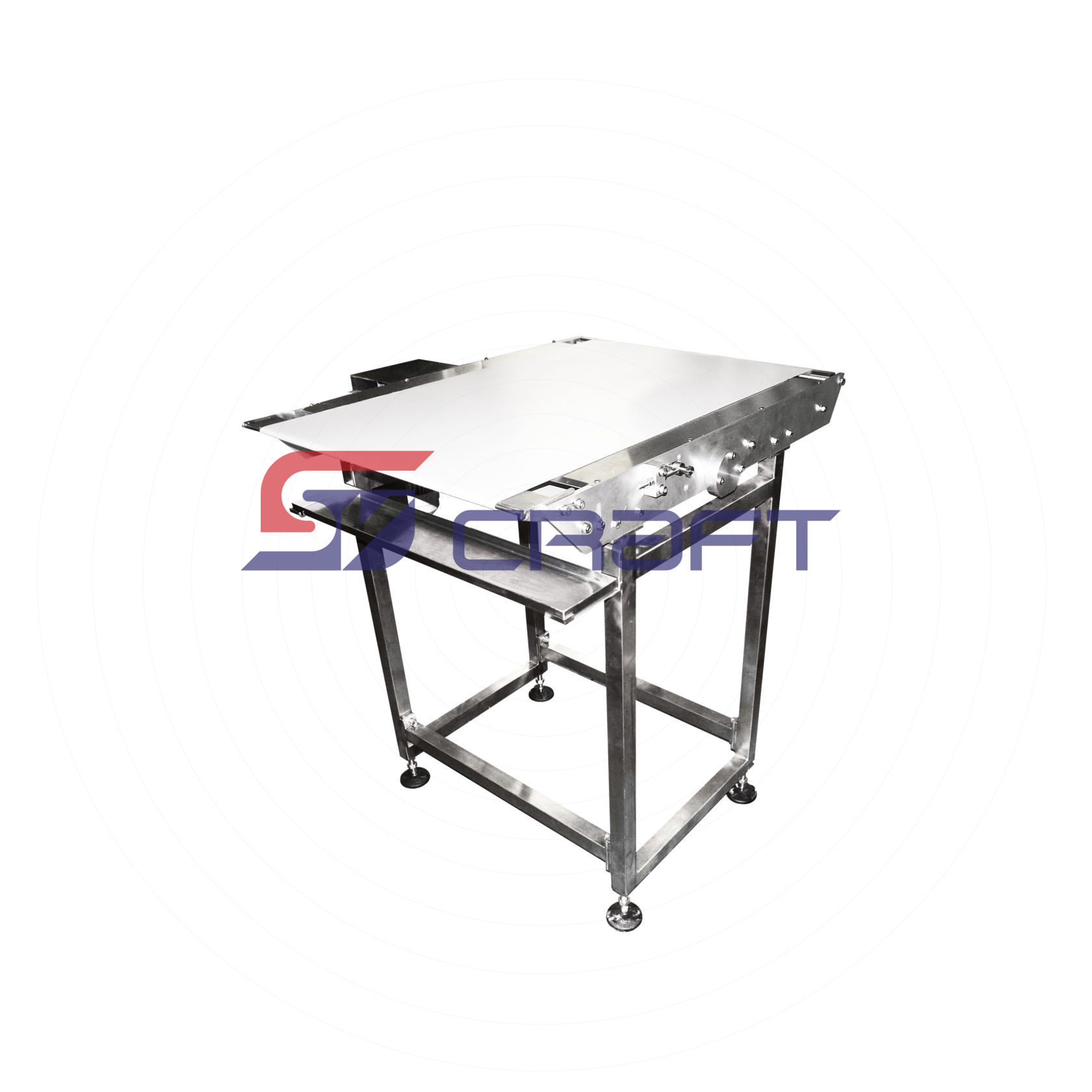

The supply unit of the filling

7

RoboGlaze glazing machine

RoboGlaze glazing equipment from SV craft company covers the products with chocolate glaze from the top, bottom or completely, in one pass.

Icing confectionery with two colored glazes on the same coating machine RoboGlaze opens up new opportunities for icing sweets, icing cookies, glazed cheeses as well as chocolate icing is used for marshmallows and other confectionery products.

Icing confectionery with two colored glazes on the same coating machine RoboGlaze opens up new opportunities for icing sweets, icing cookies, glazed cheeses as well as chocolate icing is used for marshmallows and other confectionery products.

8

RoboCool cooling tunnel

For the filling are used:

Different types of cream

Boiled condensed milk

Souffle

Jam

Marmalade

Marshmallows, etc.

Different types of cream

Boiled condensed milk

Souffle

Jam

Marmalade

Marshmallows, etc.

9

RoboDecor coating machine

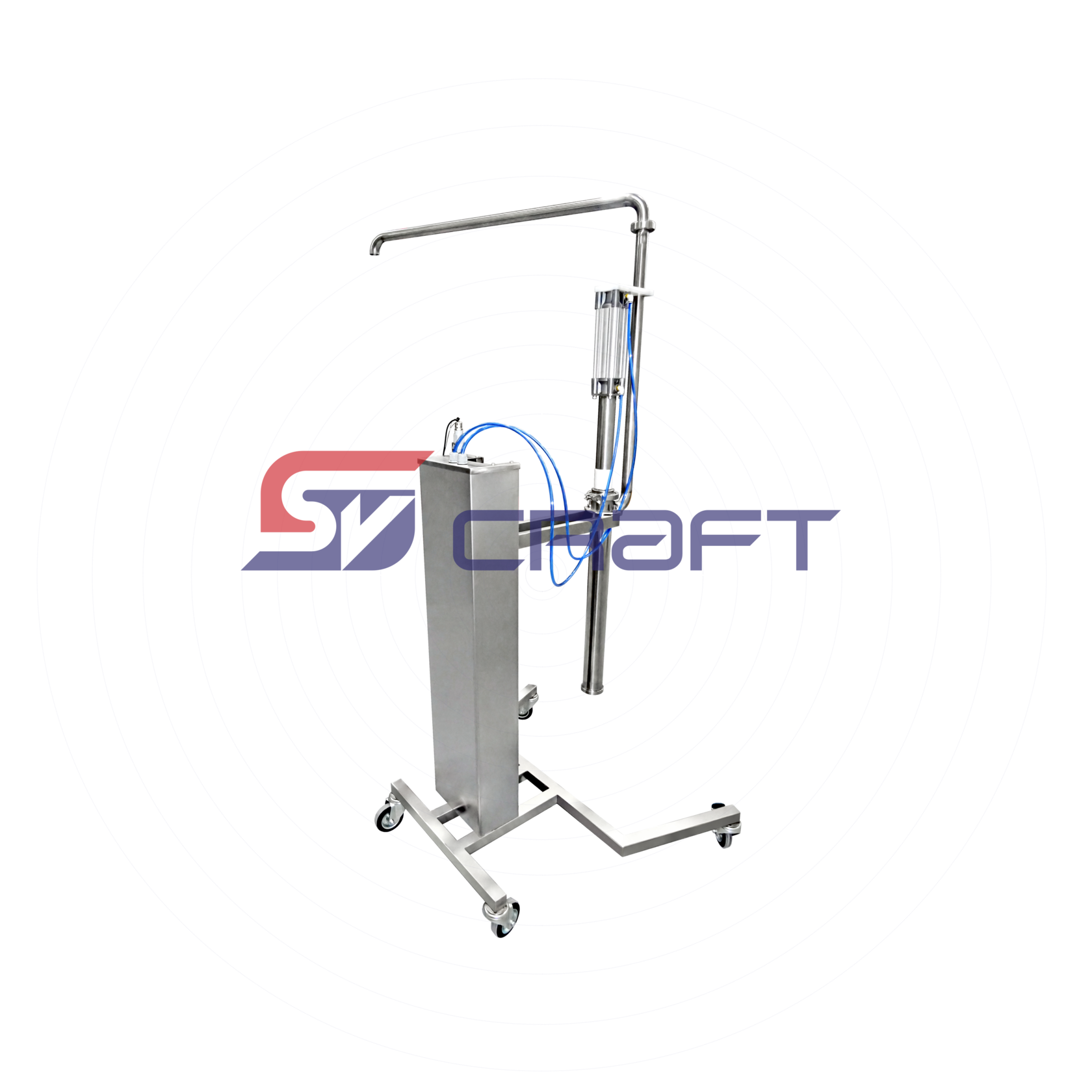

Used for melting and maintaining the operating temperature of the glaze. Complete with a pumping station and connection system, it is used for automatic maintenance of the glaze level in the working bath of the glazing machine.

The cooling tunnel is a flow- through refrigerating chamber, inside which a conveyor belt moves .

The entrance and exit tunnel sections have adjustable dampers.

Depending on the height

for cooling products, the dampers are raised or lowered. This reduces the loss of cold.

The input node performs the function of a normal conveyor. It receives products for further cooling.

When opening the tunnel covers, they are conveniently fixed with gas springs. In the cooling tunnel can

a cold table is installed to cool the bottom of the product.

The entrance and exit tunnel sections have adjustable dampers.

Depending on the height

for cooling products, the dampers are raised or lowered. This reduces the loss of cold.

The input node performs the function of a normal conveyor. It receives products for further cooling.

When opening the tunnel covers, they are conveniently fixed with gas springs. In the cooling tunnel can

a cold table is installed to cool the bottom of the product.

Technical parameters

Technical parameters

Free consultation

Free consultation