Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

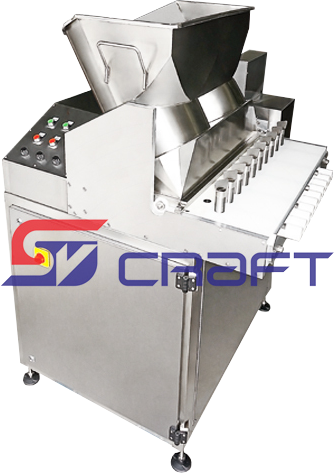

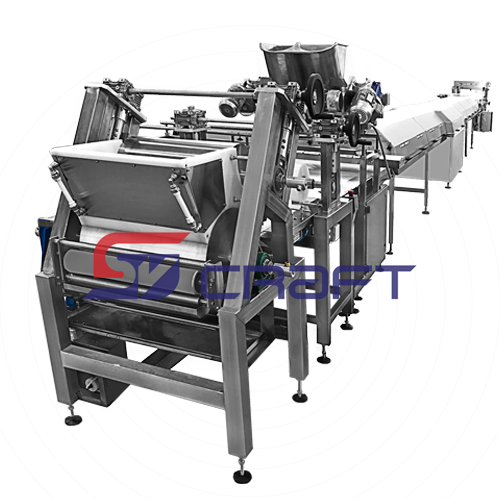

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

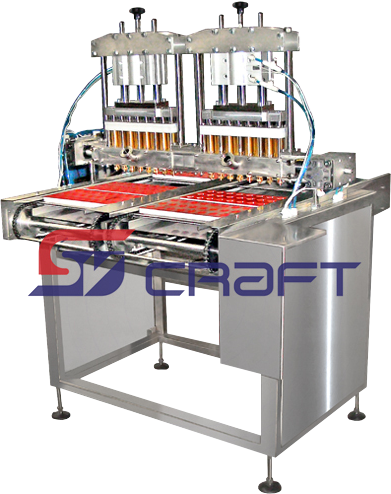

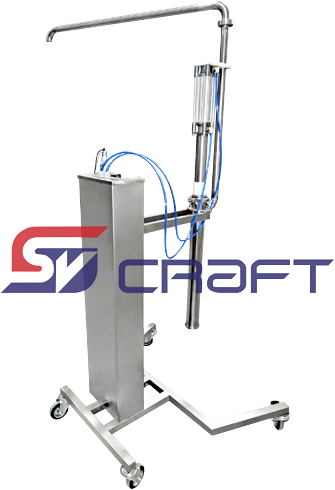

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

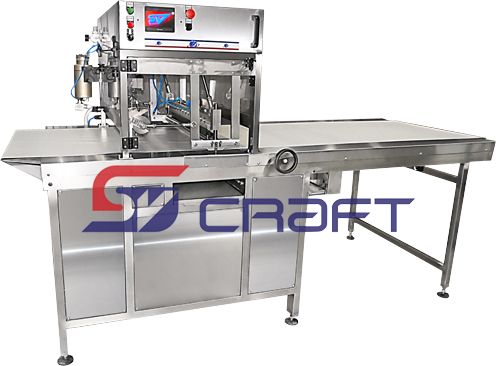

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

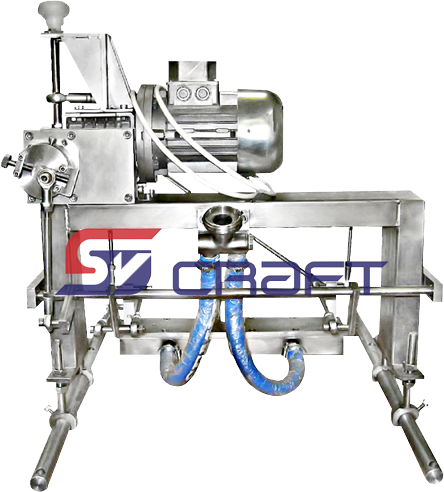

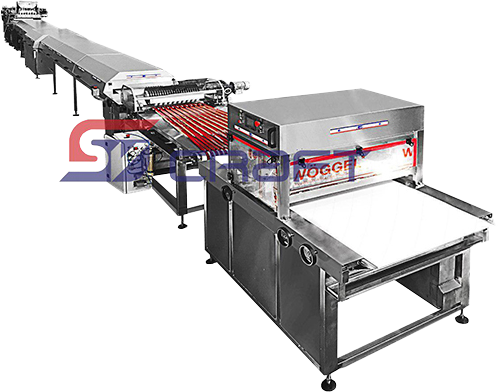

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

Примечание

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

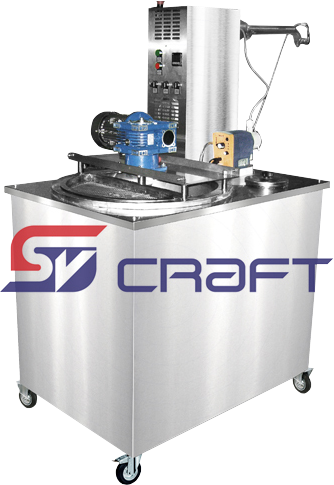

Pouring machine RoboJelly-W

Pouring machine RoboJelly-W

Оставьте заявку

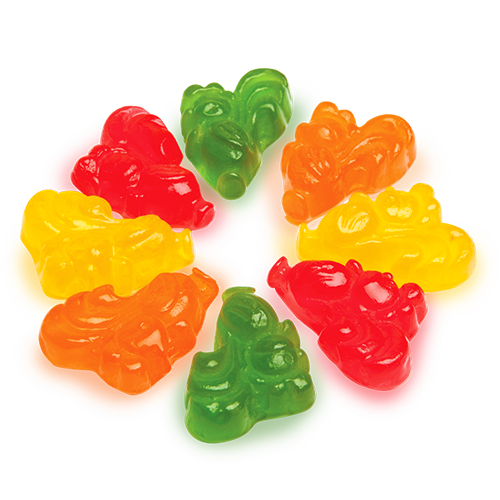

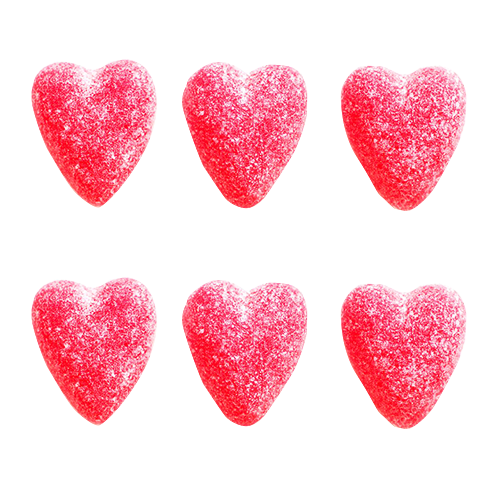

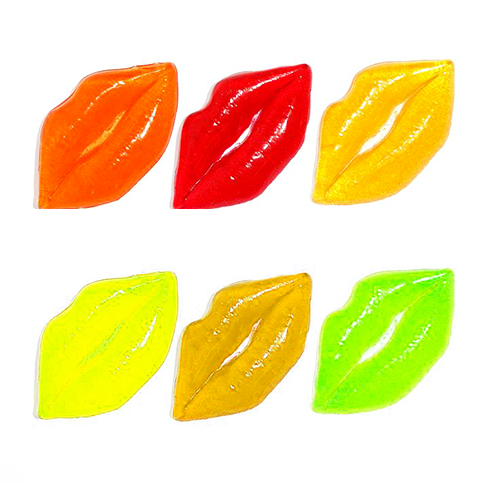

Products produced on this equipment

Products produced on this equipment

Video

Video

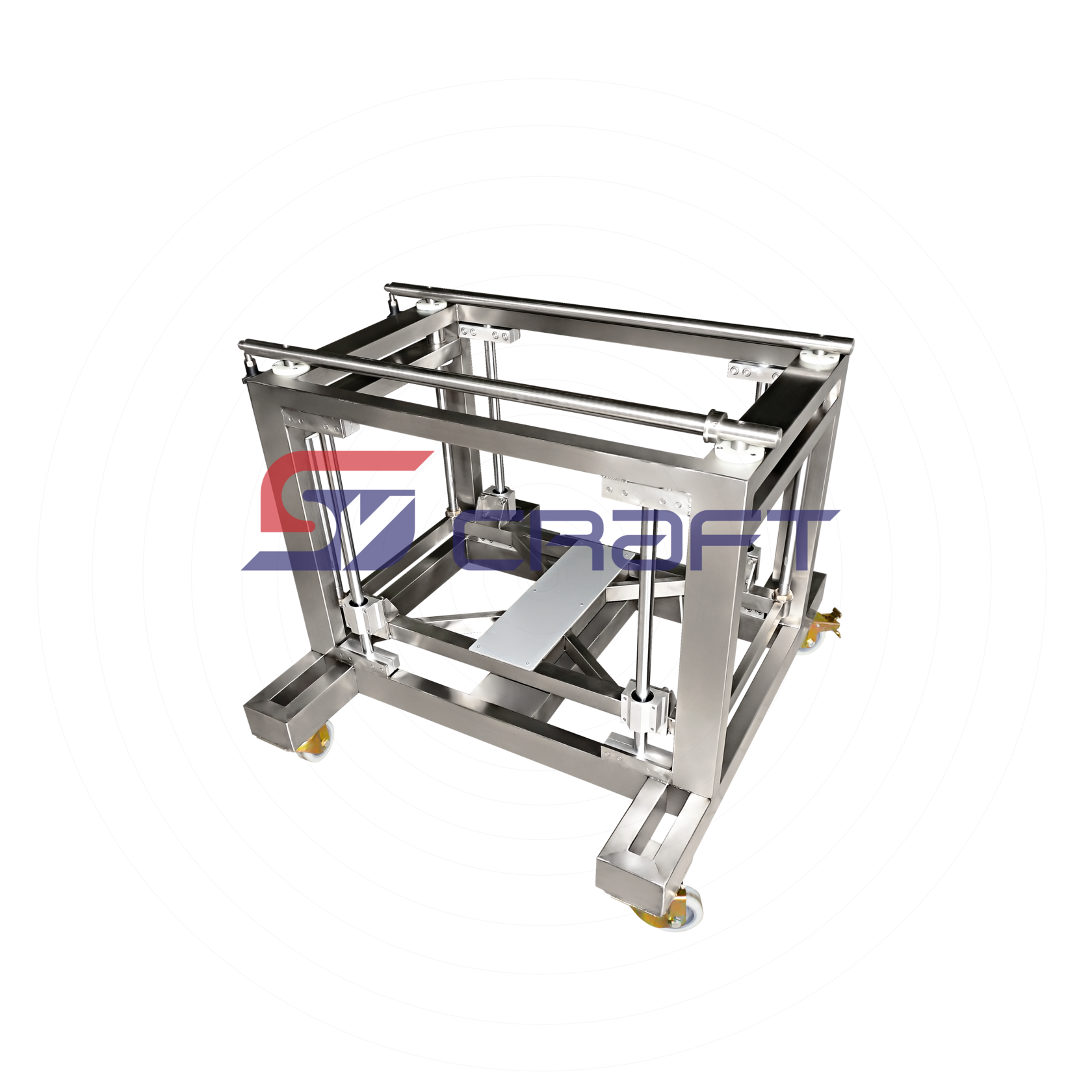

The basic features of the RoboJelly-W

The basic features of the RoboJelly-W

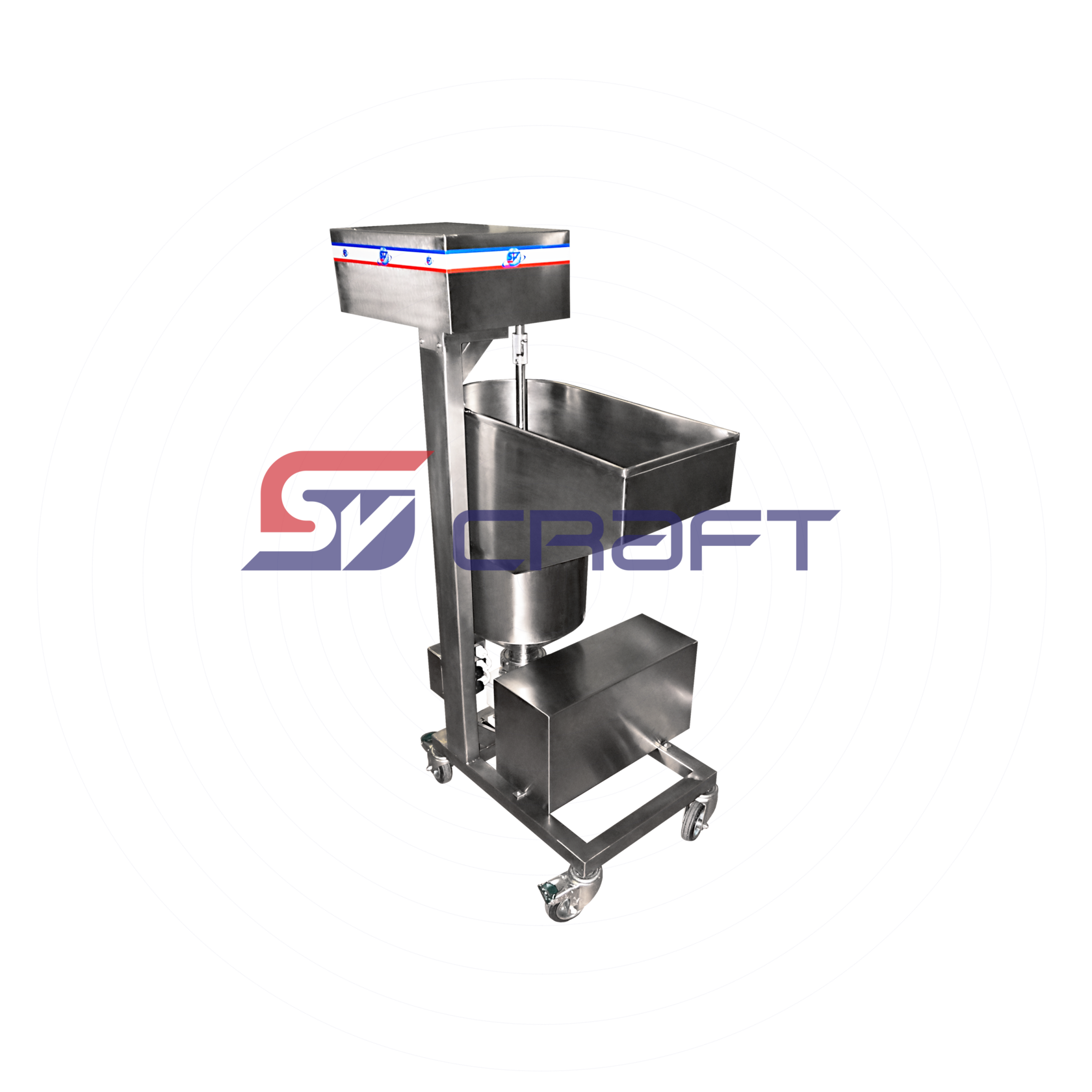

The machine has a volumetric dosing unit with a piston type spool mechanism and manual adjustment of the dose.

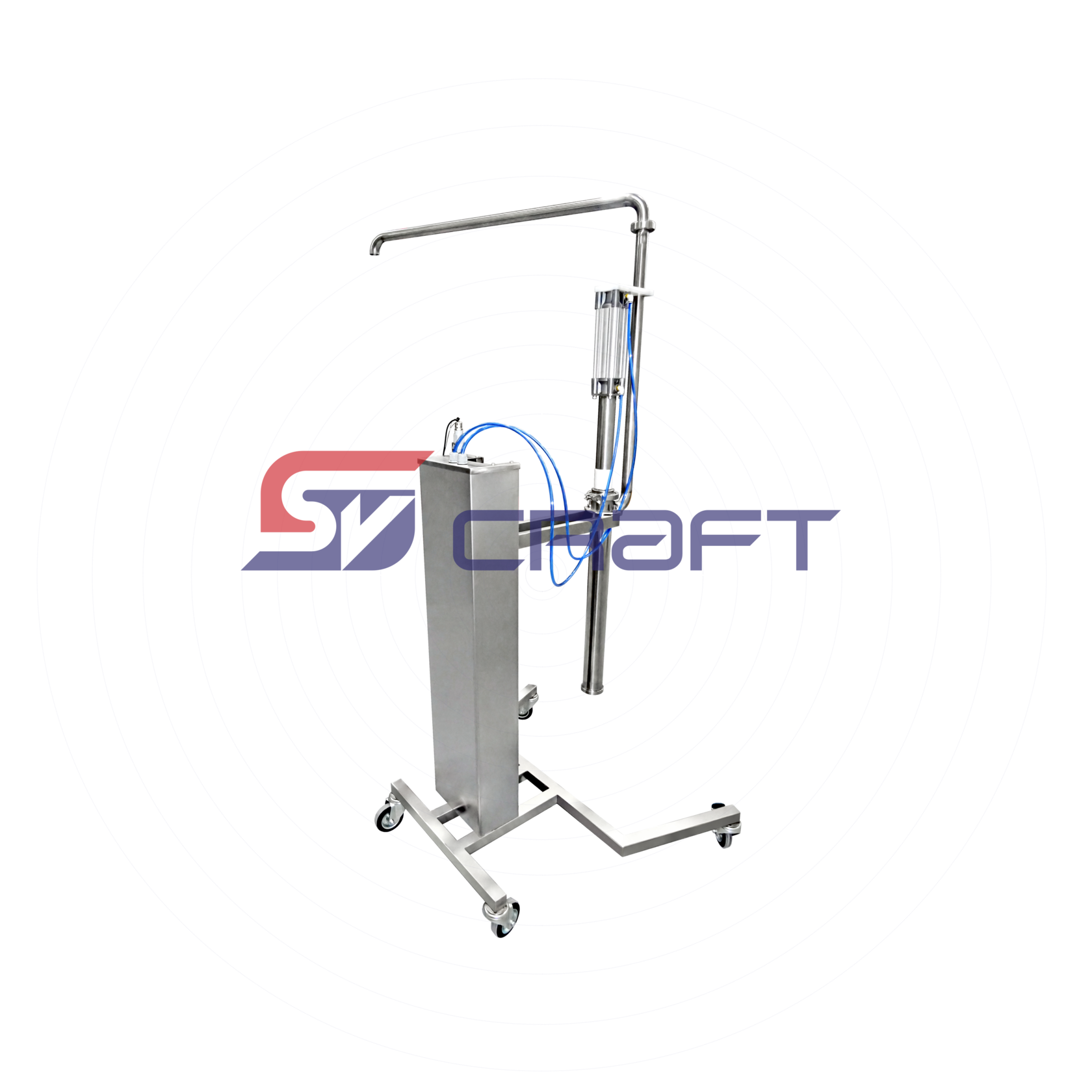

The marmalade supply unit supplies the marmalade mass to the dispenser, consists of a tank with a stirrer, a feed pump, a tank for acid, a dosing pump for acid, an active stirrer for mixing the marmalade mass and acid before casting. The temperature of the tank and pipelines is maintained by a heated water jacket. The amount of acid supplied is determined automatically by the metering pump.

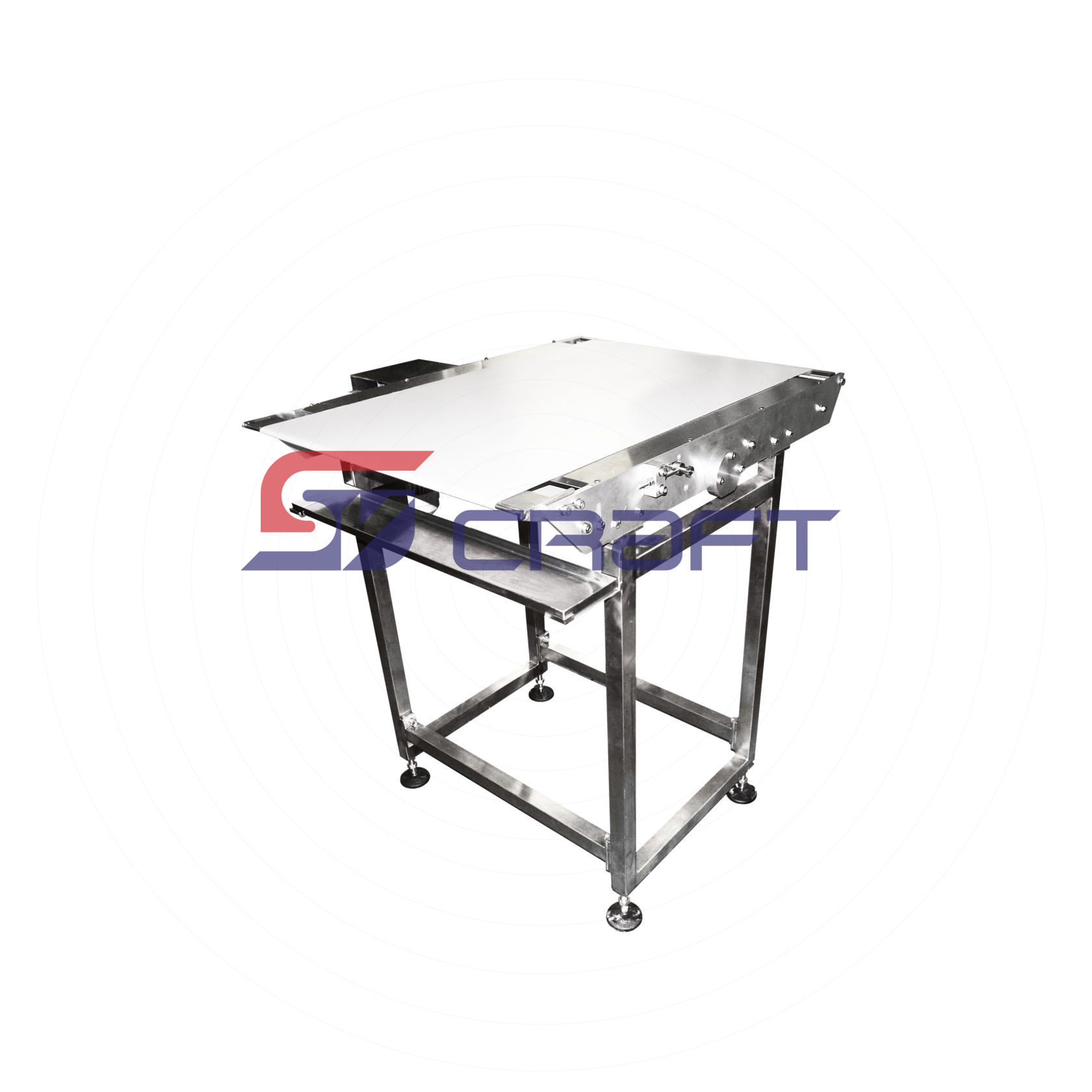

Silicone molds are installed on a chain conveyor. Moving the forms on the conveyor is performed step by step, the parameters are adjusted using the program from the display.

The marmalade supply unit supplies the marmalade mass to the dispenser, consists of a tank with a stirrer, a feed pump, a tank for acid, a dosing pump for acid, an active stirrer for mixing the marmalade mass and acid before casting. The temperature of the tank and pipelines is maintained by a heated water jacket. The amount of acid supplied is determined automatically by the metering pump.

Silicone molds are installed on a chain conveyor. Moving the forms on the conveyor is performed step by step, the parameters are adjusted using the program from the display.

1

Smooth adjustment of the marmalade dose

2

Uniform regulation of the injected acid dose

3

Measured conveyor speed control

4

Support for marmalade temperature up to 90°C

5

Monitoring the load on the engine

6

Washing the machine without disassembly

The machine has a volumetric dosing unit with a piston type spool mechanism and manual adjustment of the dose.

The marmalade supply unit supplies the marmalade mass to the dispenser, consists of a tank with a stirrer, a feed pump, a tank for acid, a dosing pump for acid, an active stirrer for mixing the marmalade mass and acid before casting. The temperature of the tank and pipelines is maintained by a heated water jacket. The amount of acid supplied is determined automatically by the metering pump.

Silicone molds are installed on a chain conveyor. Moving the forms on the conveyor is performed step by step, the parameters are adjusted using the program from the display.

The marmalade supply unit supplies the marmalade mass to the dispenser, consists of a tank with a stirrer, a feed pump, a tank for acid, a dosing pump for acid, an active stirrer for mixing the marmalade mass and acid before casting. The temperature of the tank and pipelines is maintained by a heated water jacket. The amount of acid supplied is determined automatically by the metering pump.

Silicone molds are installed on a chain conveyor. Moving the forms on the conveyor is performed step by step, the parameters are adjusted using the program from the display.

1

Smooth adjustment of the marmalade dose

2

Uniform regulation of the injected acid dose

3

Measured conveyor speed control

4

Support for marmalade temperature up to 90°C

5

Monitoring the load on the engine

6

Washing the machine without disassembly

Technical parameters

Technical parameters