8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

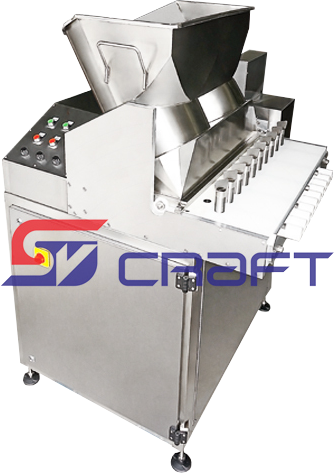

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

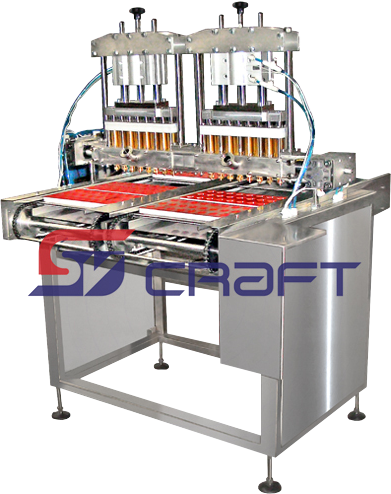

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

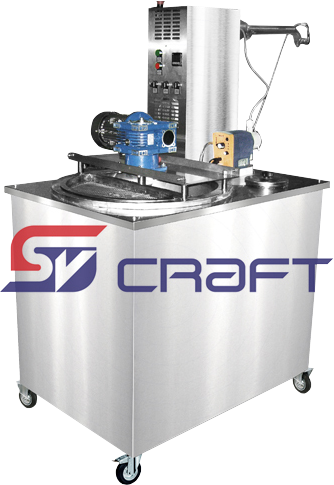

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

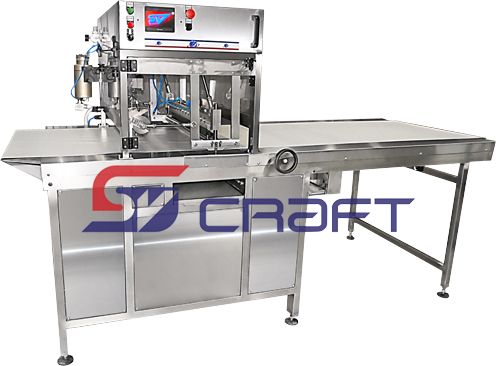

Waffle cones filling line RoboFillerVR

Waffle cones filling line RoboFillerVR

The horns are installed in the lamellas on the conveyor of the machine, after that, the injection of black or white glaze is made from the inside of the horn.

Passing through the cooling section, a protective layer of the product is formed, which prevents the inner surface of the waffle cone from getting wet.

The next stage is filling the products with a mass of filling: cottage cheese with filling, marshmallows with filling, jam, etc.

The top of the dome of the horn is sealed with a cork made of chocolate glaze or dipped in a built-in bath where it is covered with glaze.

Then the product passes through the cooling section and is automatically pushed out of the slats on the conveyor leading to the packaging unit.

Passing through the cooling section, a protective layer of the product is formed, which prevents the inner surface of the waffle cone from getting wet.

The next stage is filling the products with a mass of filling: cottage cheese with filling, marshmallows with filling, jam, etc.

The top of the dome of the horn is sealed with a cork made of chocolate glaze or dipped in a built-in bath where it is covered with glaze.

Then the product passes through the cooling section and is automatically pushed out of the slats on the conveyor leading to the packaging unit.

Price on request

Customized

The horns are installed in the lamellas on the conveyor of the machine, after that, the injection of black or white glaze is made from the inside of the horn.

Passing through the cooling section, a protective layer of the product is formed, which prevents the inner surface of the waffle cone from getting wet.

The next stage is filling the products with a mass of filling: cottage cheese with filling, marshmallows with filling, jam, etc.

The top of the dome of the horn is sealed with a cork made of chocolate glaze or dipped in a built-in bath where it is covered with glaze.

Then the product passes through the cooling section and is automatically pushed out of the slats on the conveyor leading to the packaging unit.

Passing through the cooling section, a protective layer of the product is formed, which prevents the inner surface of the waffle cone from getting wet.

The next stage is filling the products with a mass of filling: cottage cheese with filling, marshmallows with filling, jam, etc.

The top of the dome of the horn is sealed with a cork made of chocolate glaze or dipped in a built-in bath where it is covered with glaze.

Then the product passes through the cooling section and is automatically pushed out of the slats on the conveyor leading to the packaging unit.

Price on request

Customized

Оставьте заявку

Products produced on this equipment

Products produced on this equipment

Video

Video

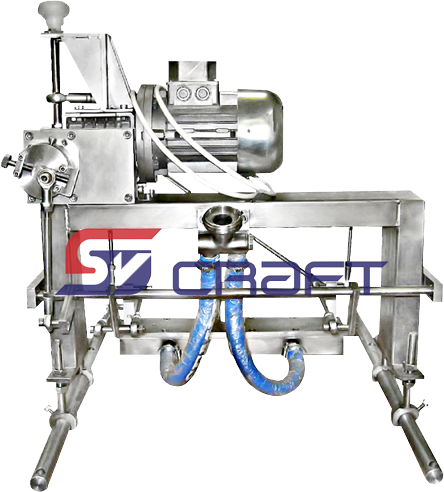

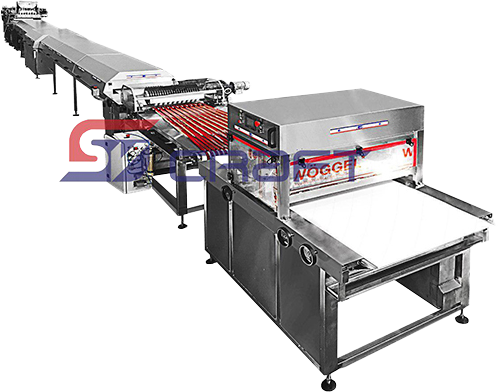

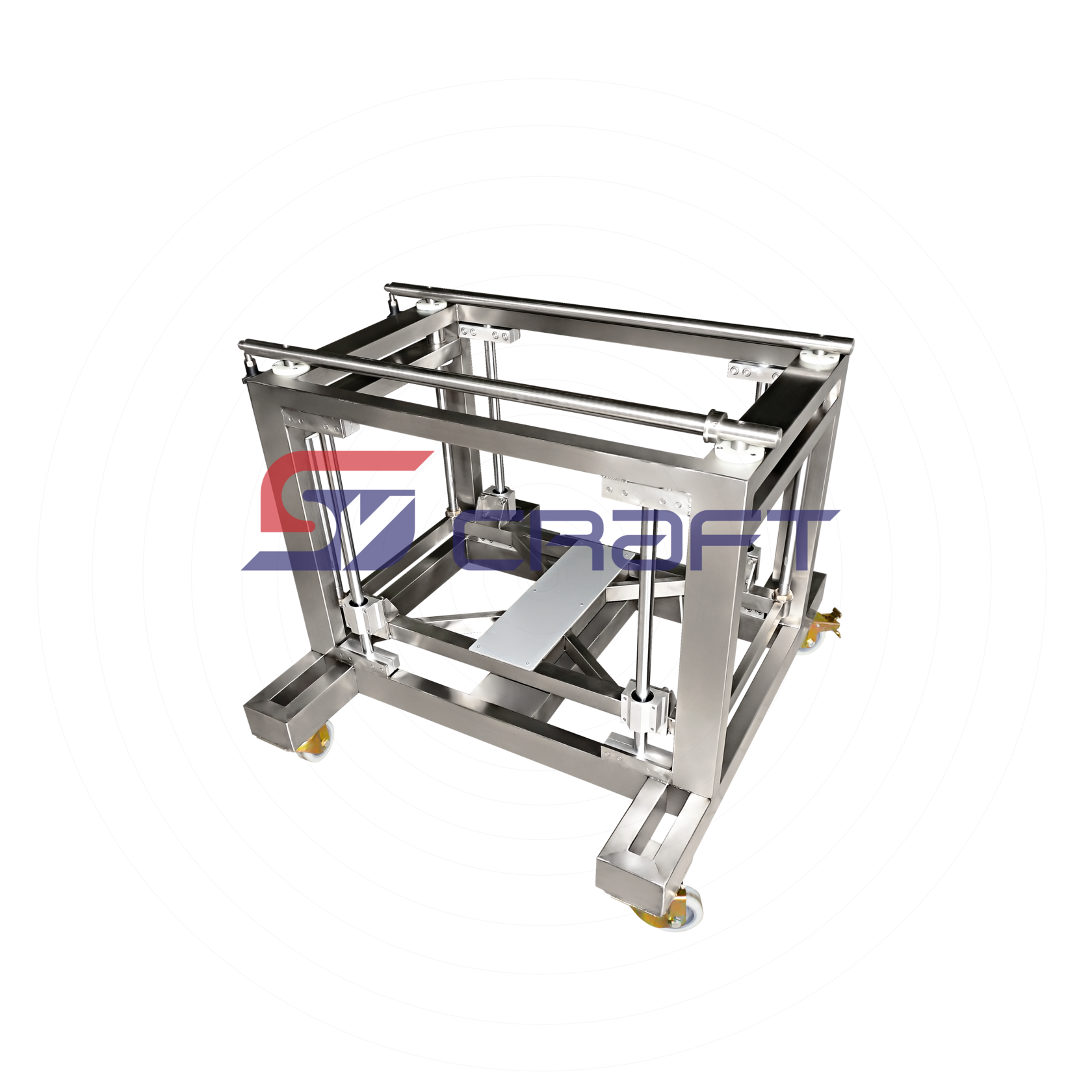

The line includes the following equipment:

The line includes the following equipment:

1

The conveyor tapes

With loading zone

2

Stamp

To fix the tubes in the conveyor cassette

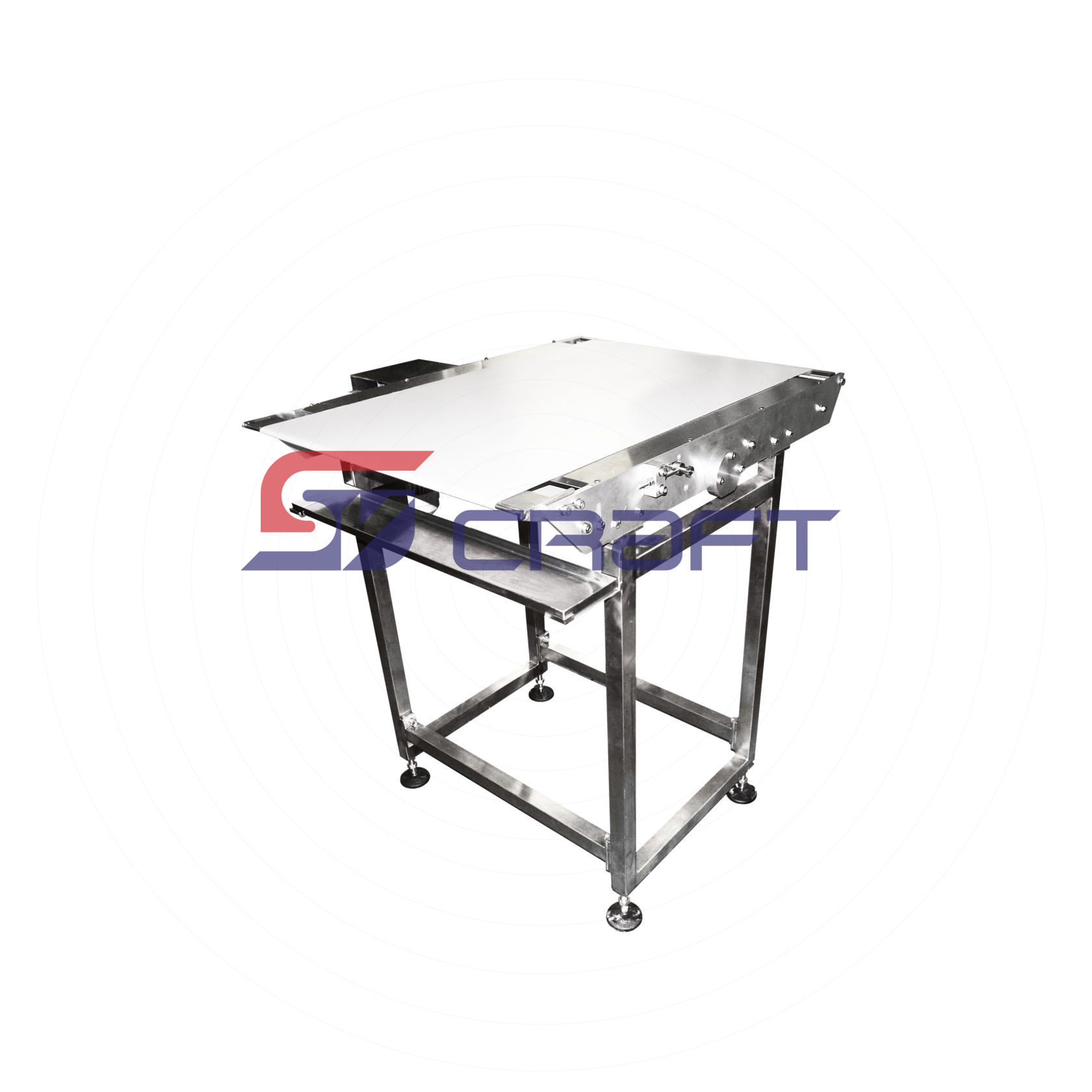

3

Bath with nozzles

For glazing the inner walls of tubes

4

Refrigerated cabinet

With smooth temperature control

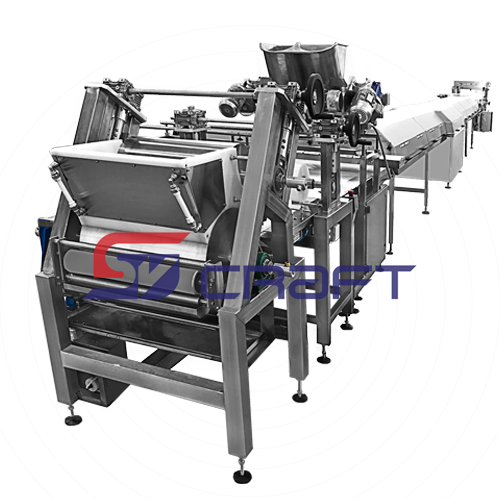

5

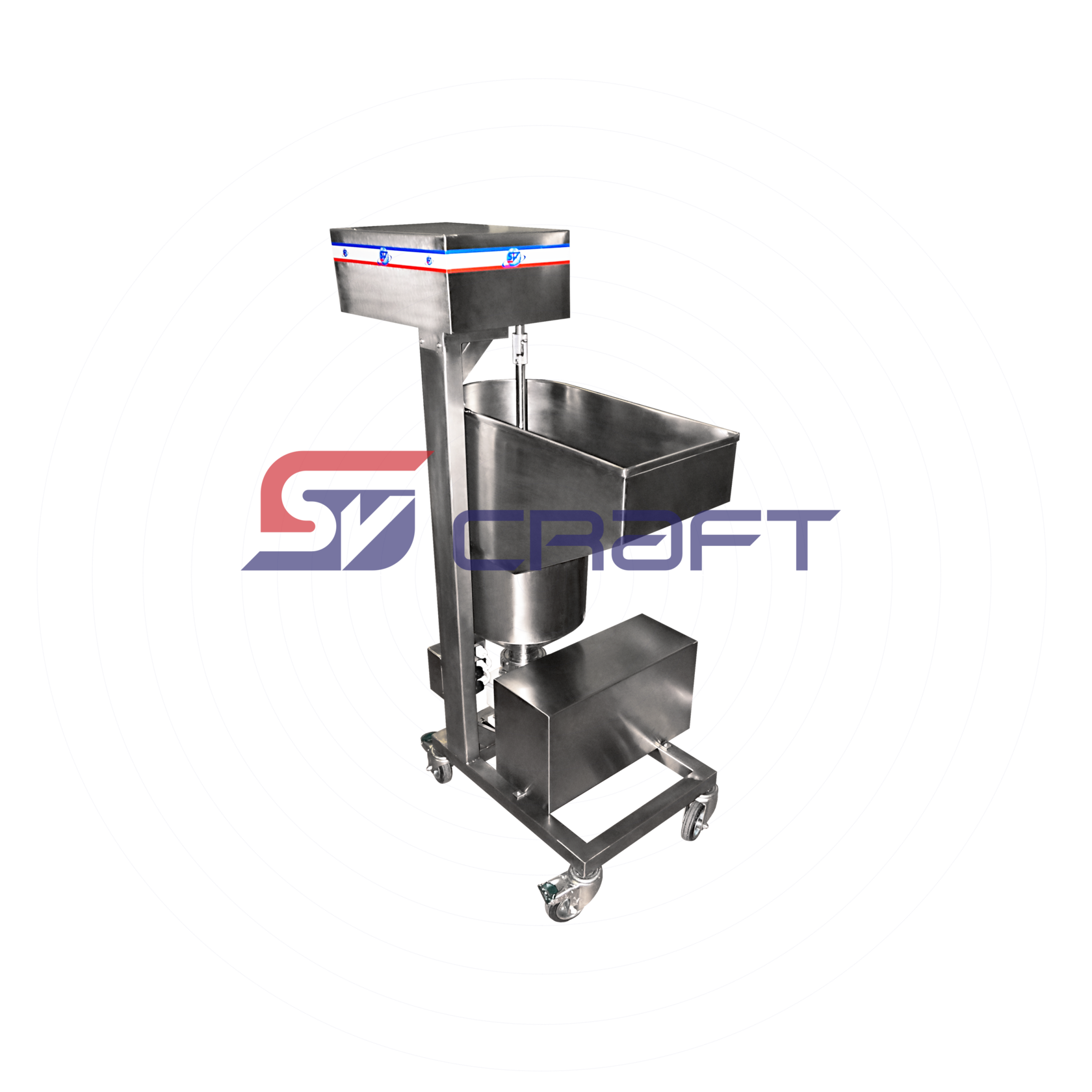

Depositing head

For filling tubes with filling with the possibility of adding fruit fragments up to 2 (two) mm per 9 streams

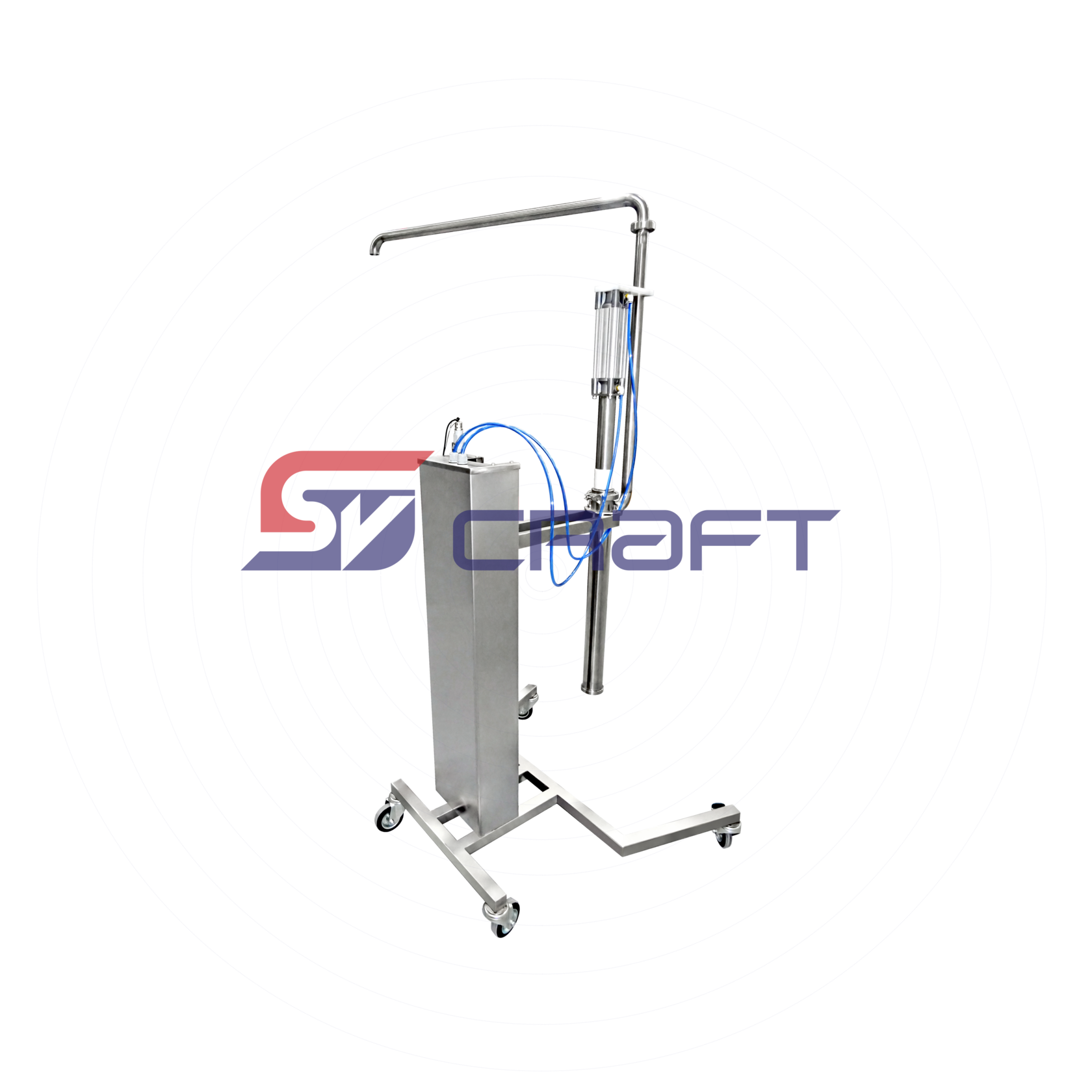

6

Tub of dipping tubes in chocolate glaze

7

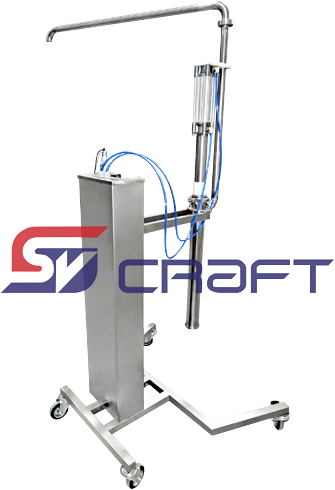

Pumping plant

with filtration systems

8

The node of discharge tubes to the discharge conveyor.

Technical parameters

Technical parameters

Free consultation

Free consultation