8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

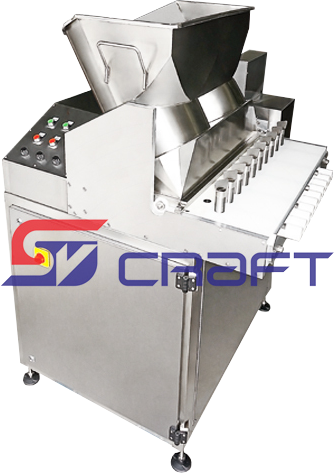

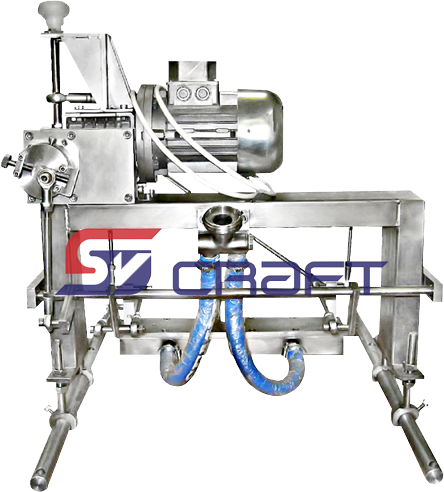

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

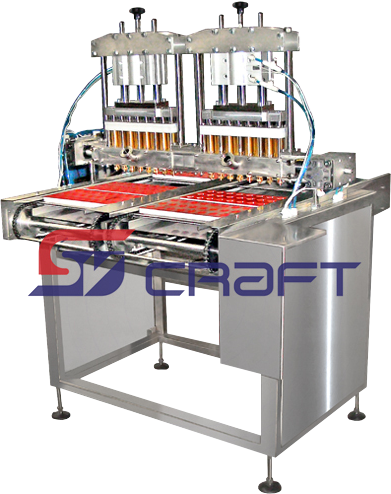

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

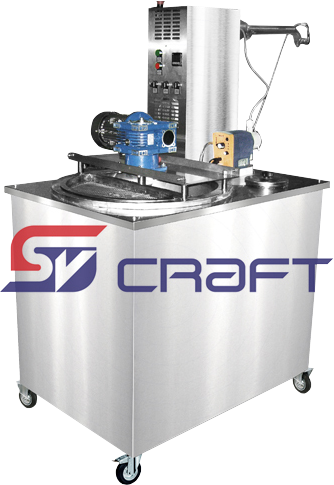

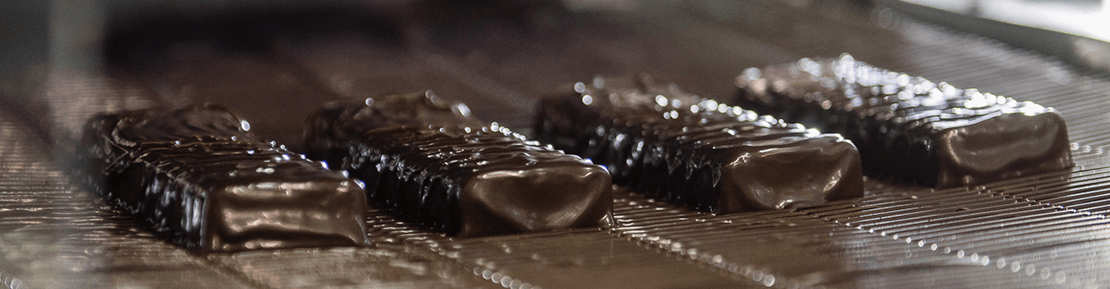

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

Extruding - forming machine RoboExtruderBar

Extruding - forming machine RoboExtruderBar

Примечание

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

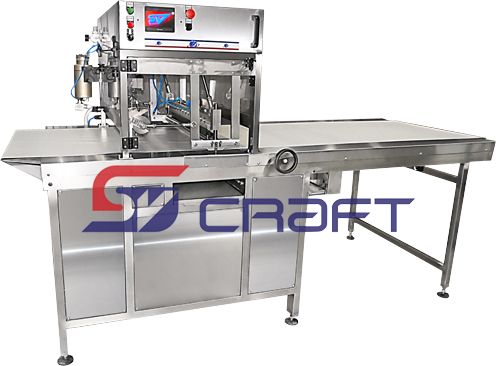

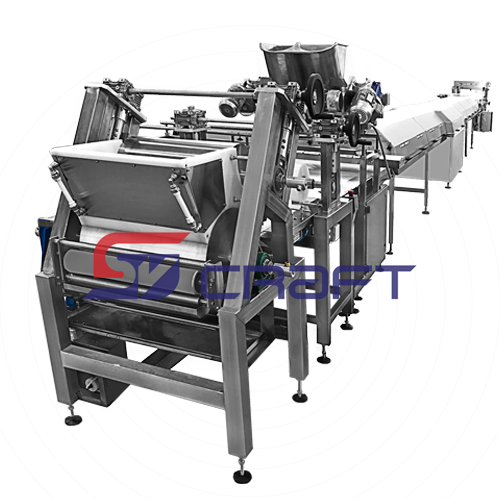

The machine with screw mass injection is designed for forming fruit, protein, protein, praline, hematogenic bars and sweets of various shapes.

The machine can also be equipped with a filling feeding unit and diaphragm cutting, which will allow you to produce a wider range of products of various shapes, such as: bars with filling, sweets with filling, dome- shaped sweets with filling.

The machine can also be equipped with a filling feeding unit and diaphragm cutting, which will allow you to produce a wider range of products of various shapes, such as: bars with filling, sweets with filling, dome- shaped sweets with filling.

Price on request

Customized

RoboExtruderBar extrusion molding machine

Additional options

Heating

bunkers

bunkers

Diaphragm

cutting

cutting

Pressure

device

device

Heating

screw chamber

screw chamber

Stringed

cutting

cutting

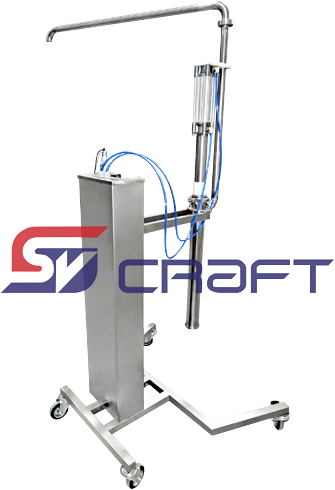

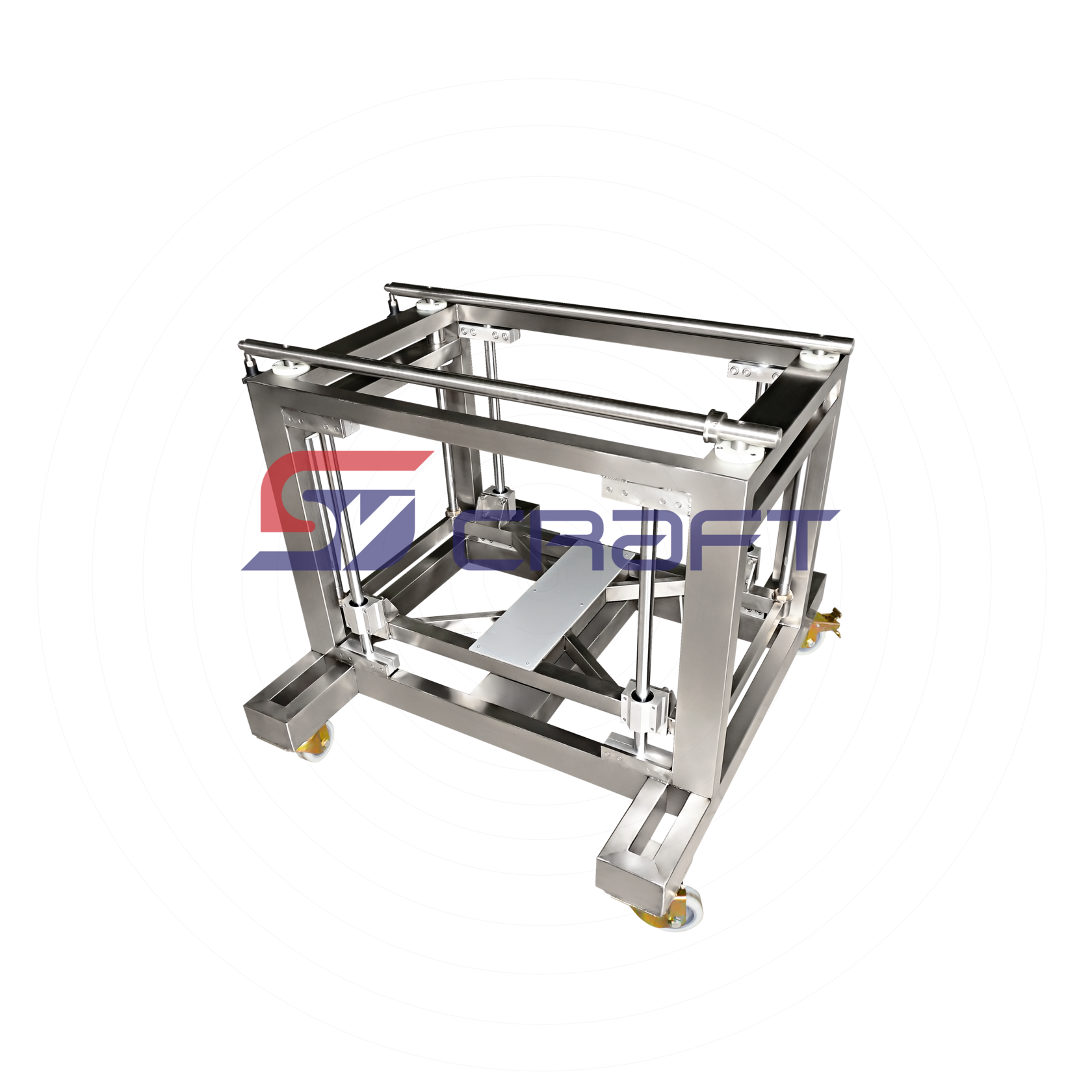

Trolley for

removing the head

removing the head

The machine with screw mass injection is designed for forming fruit, protein, protein, praline, hematogenic bars and sweets of various shapes.

The machine can also be equipped with a filling feeding unit and diaphragm cutting, which will allow you to produce a wider range of products of various shapes, such as: bars with filling, sweets with filling, dome- shaped sweets with filling.

The machine can also be equipped with a filling feeding unit and diaphragm cutting, which will allow you to produce a wider range of products of various shapes, such as: bars with filling, sweets with filling, dome- shaped sweets with filling.

Price on request

Customized

RoboExtruderBar extrusion molding machine

Additional options

Heating

bunkers

bunkers

Diaphragm

cutting

cutting

Pressure

device

device

Heating

screw chamber

screw chamber

Stringed

cutting

cutting

Trolley for

removing the head

removing the head

Оставьте заявку

PRODUCTS PRODUCED ON THIS EQUIPMENT

PRODUCTS PRODUCED ON THIS EQUIPMENT

Video

Video

Basic features of RoboExtruderBar

Basic features of RoboExtruderBar

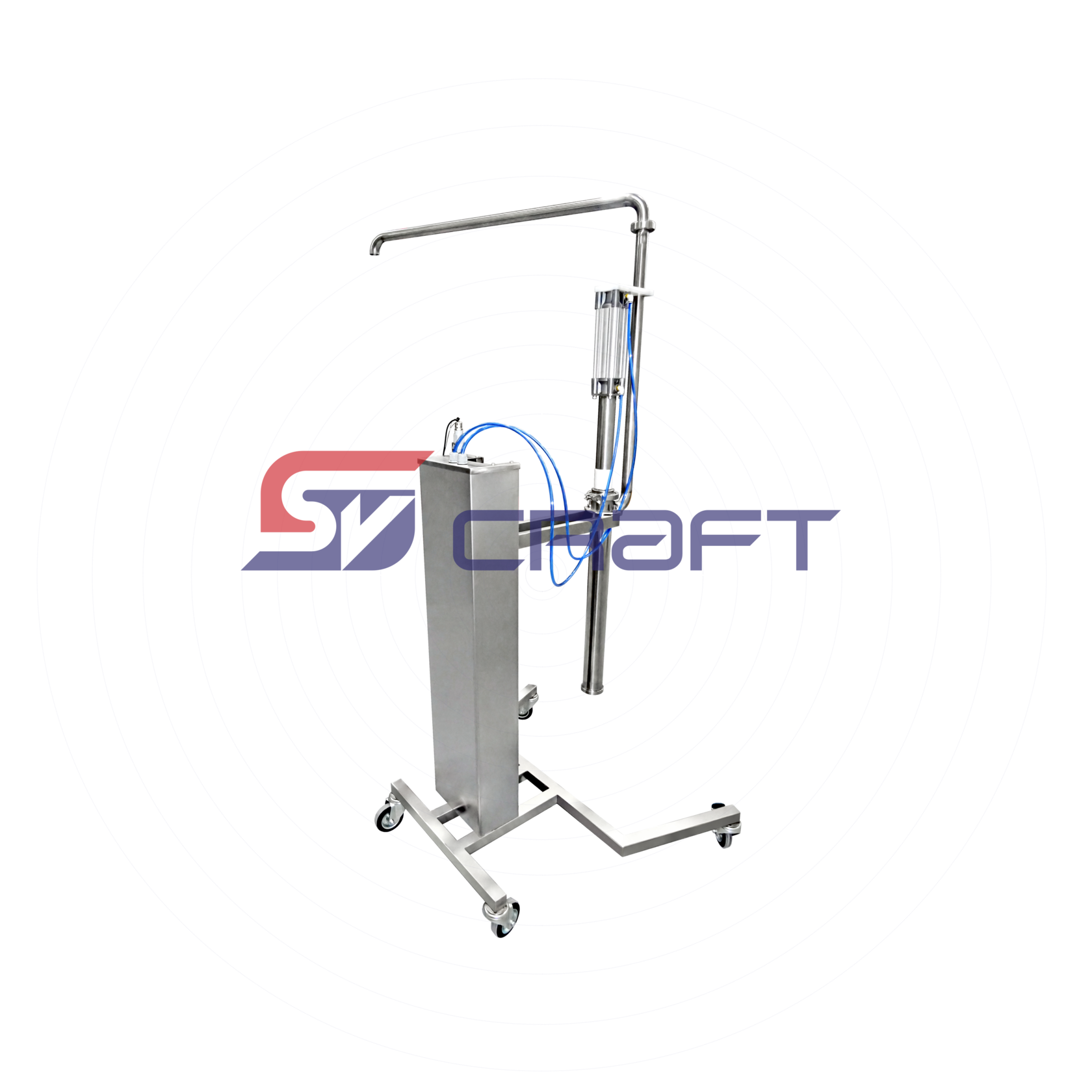

The principle of operation of the extrusion molding machine "RoboExtruderBar" is based on screw injection, which allows you to plant a very large range of masses (fruit, protein, protein, praline, hematogenic and similar masses). In addition to the screw chamber, a filling feed unit can be provided.

This equipment for confectionery production is installed at the entrance of the refrigeration tunnel when releasing sweets and bars. To obtain products of domed or round shape, the machine is equipped with diaphragm cutting. To obtain products by laying out the harness on the tape, the machine is equipped with a guillotine cutting device.

The machine is controlled by a touch screen.

This equipment for confectionery production is installed at the entrance of the refrigeration tunnel when releasing sweets and bars. To obtain products of domed or round shape, the machine is equipped with diaphragm cutting. To obtain products by laying out the harness on the tape, the machine is equipped with a guillotine cutting device.

The machine is controlled by a touch screen.

1

Screw injection

populace

populace

2

High speed diaphragm cutting mechanism

3

Set of nozzles according to the customer 's technical specification

Additional sets of nozzles are used for forming bundles of different cross sections

4

The machine is controlled from the touch screen

The principle of operation of the extrusion molding machine "RoboExtruder" is based on screw injection, which allows you to plant a very large range of masses (fruit, protein, protein, Proline, hematogenic and similar masses). In addition to the screw chamber, a filling feed unit can be provided.

This equipment for confectionery production is installed at the entrance of the refrigeration tunnel when releasing sweets and bars. To obtain products of domed or round shape, the machine is equipped with diaphragm cutting. To obtain products by laying out the harness on the tape, the machine is equipped with a guillotine cutting device.

The machine is controlled by a Senser display.

This equipment for confectionery production is installed at the entrance of the refrigeration tunnel when releasing sweets and bars. To obtain products of domed or round shape, the machine is equipped with diaphragm cutting. To obtain products by laying out the harness on the tape, the machine is equipped with a guillotine cutting device.

The machine is controlled by a Senser display.

1

Screw discharge

populace

populace

2

High speed diaphragm cutting mechanism

3

Set of nozzles according to the customer's specifications

Additional sets of nozzles are used for forming bundles of different cross sections

4

The machine is controlled from a touch screen

Additional equipment

Additional equipment

1

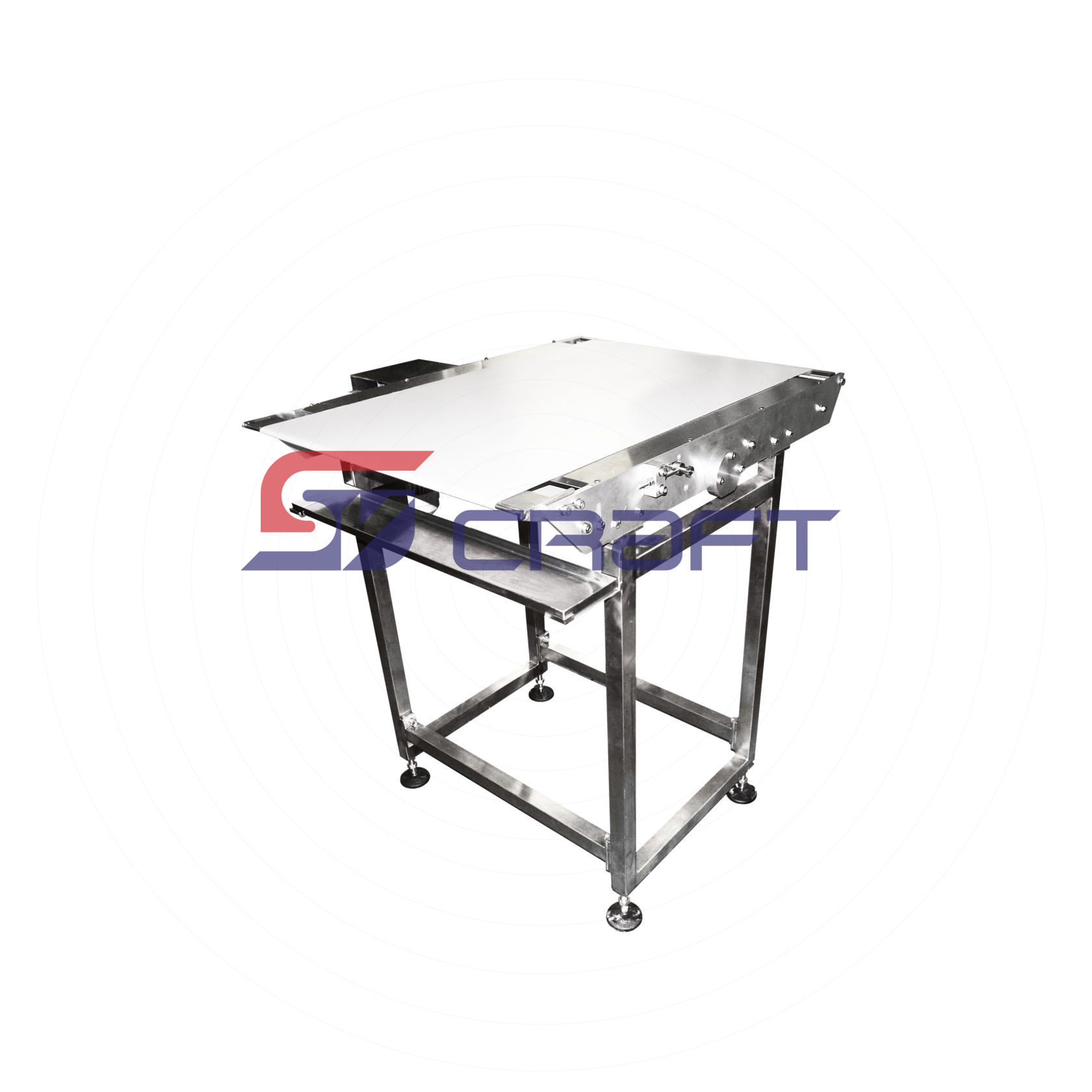

The guillotine cutting mechanism is installed at the end of the cooling tunnel

2

Heating of bins and screw chamber

3

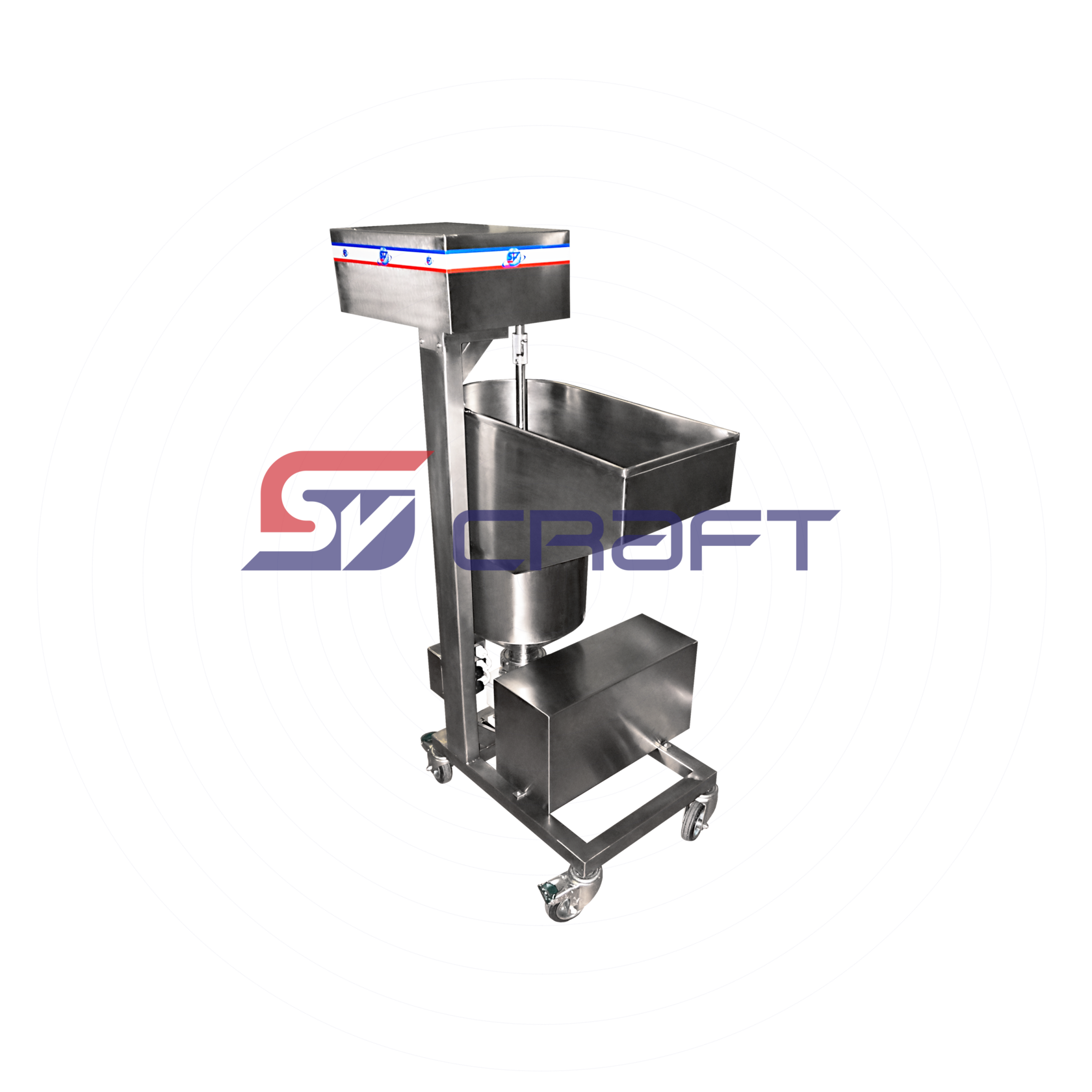

Roll-tested filling feed unit

1

The guillotine cutting mechanism is installed at the end of the cooling tunnel

2

Heating of bins and screw chamber

3

Roll-tested filling feed unit

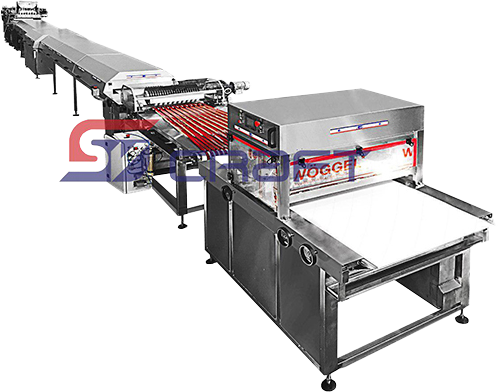

RoboExtruderBar is embedded in lines

RoboExtruderBar is embedded in lines

Muesli line

The line is designed for the formation and production of granola bars , as well as bars such as "Snickers", "Mars", products consisting of bulk components (cereals, nuts, candied fruits , etc. ), and sugar-treacle syrup.

Line of fruit candies and bars

Designed for the production of candy cases from ground dried fruits with filling.

Line of protein bars

The line is designed for the formation and production of protein bars of different shapes (rectangle, hemisphere, square), bars with filling, two- color bars.

Technical parameters

Technical parameters

*Уточняются после заполнения ТЗ заказчика