8 499-707-19-51

Sales department

Russian manufacturer of confectionery and food equipment

E-mail: market@svcraft.ru

8 800-707-77-32

Call in Russia

Free

Mon-Fri: 9:00 to 18:00

Depositing machines

For cookies, sweets, bakery dough products manufacturing

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

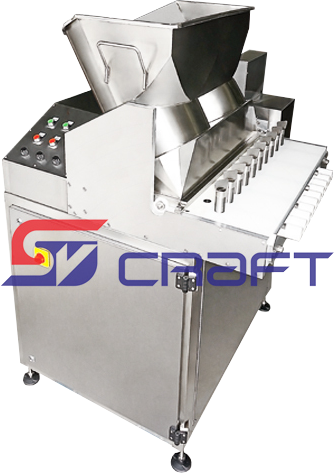

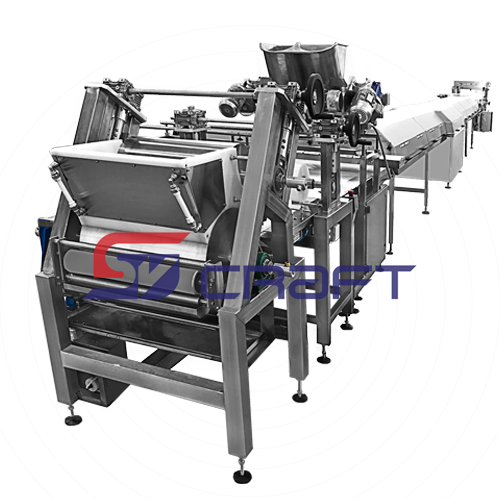

Extruding – forming machines

High-performance devices, allow to produce a variety of products made of choux paste, raw dough, cookie dough with fillings, sweets as pralines, candied roasted nuts, cream toffee and etc.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

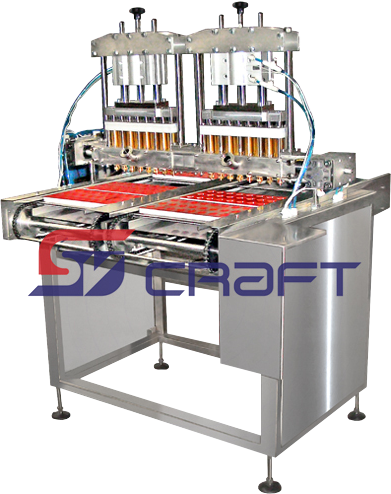

Pouring machines

For depositing or pouring out of liquid confectionery masses into the form

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Used equipment

Optional equipment

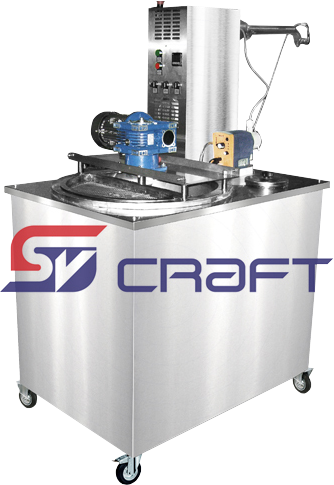

Glazing (icing) machines

For glazing of confectionery products. "RoboGlaze" allows you to cover the product from bottom ,top , completely, with decoration and so on.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

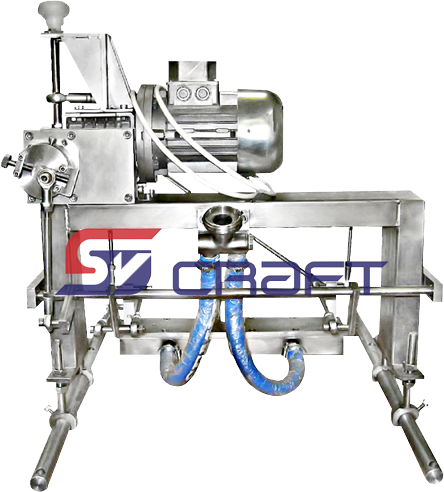

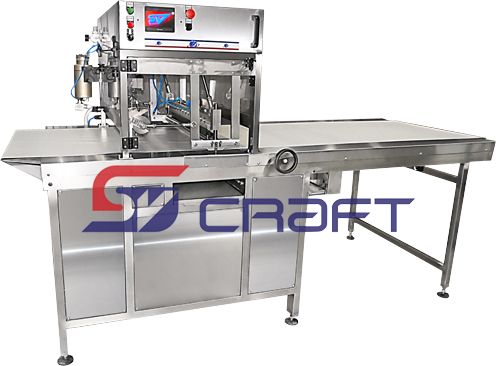

Filling machines

For the production and filling of confectionery products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cooling and drying

For cooling of glazed and decorated confectionery products deposited on the belt

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Cutting machines

Guillotine and disc cutting for transversal or longitudinal cutting of continuous bundles (straps) or continuous layer of confectionery mass

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Curd cheese snacks line

For forming, glazing (icing)and packaging of ready products

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Confectionary lines

For production of cookies, sweets, gingerbread cookies, «muesli» bars, waffle tubes и cones with fillings, curd cheese snacks and many others.

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Granola (Muesli) bars line

The line is designed for forming and production of granola (muesli) bars

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Optional equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Used equipment

Depositing machines

Extruding –forming machines

Pouring machines

Glazing (icing) machines

Filling machines

Cooling and drying

Cutting machines

Curd cheese snacks line

Confectionary lines

Granola (Muesli) line

Optional equipment

Used equipment

Leave a request

Privacy policy

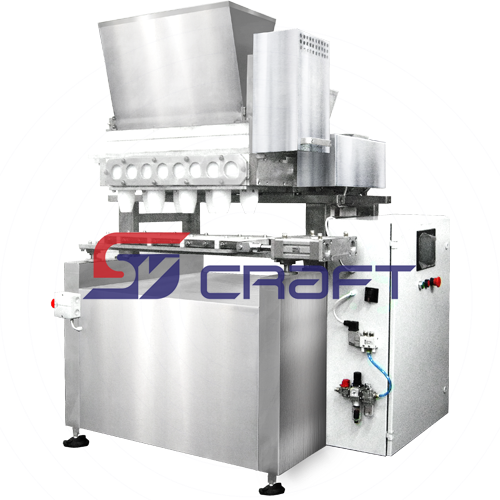

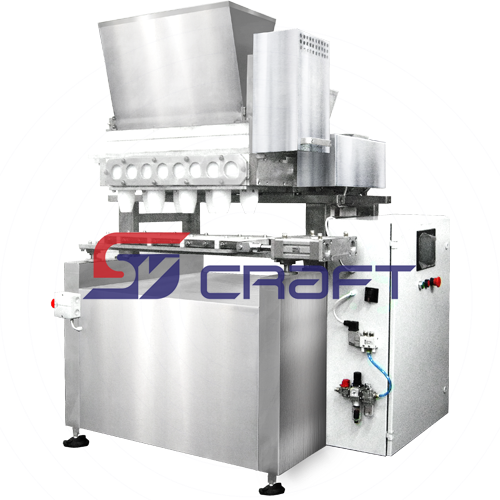

Equipment for the production of gingerbread RoboExtruder

Equipment for the production of gingerbread RoboExtruder

Примечание

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

Комплектация поставки согласовывается при заказе оборудования. Комплектующие изделия могут так же поставляться отдельно, по желанию Заказчика.

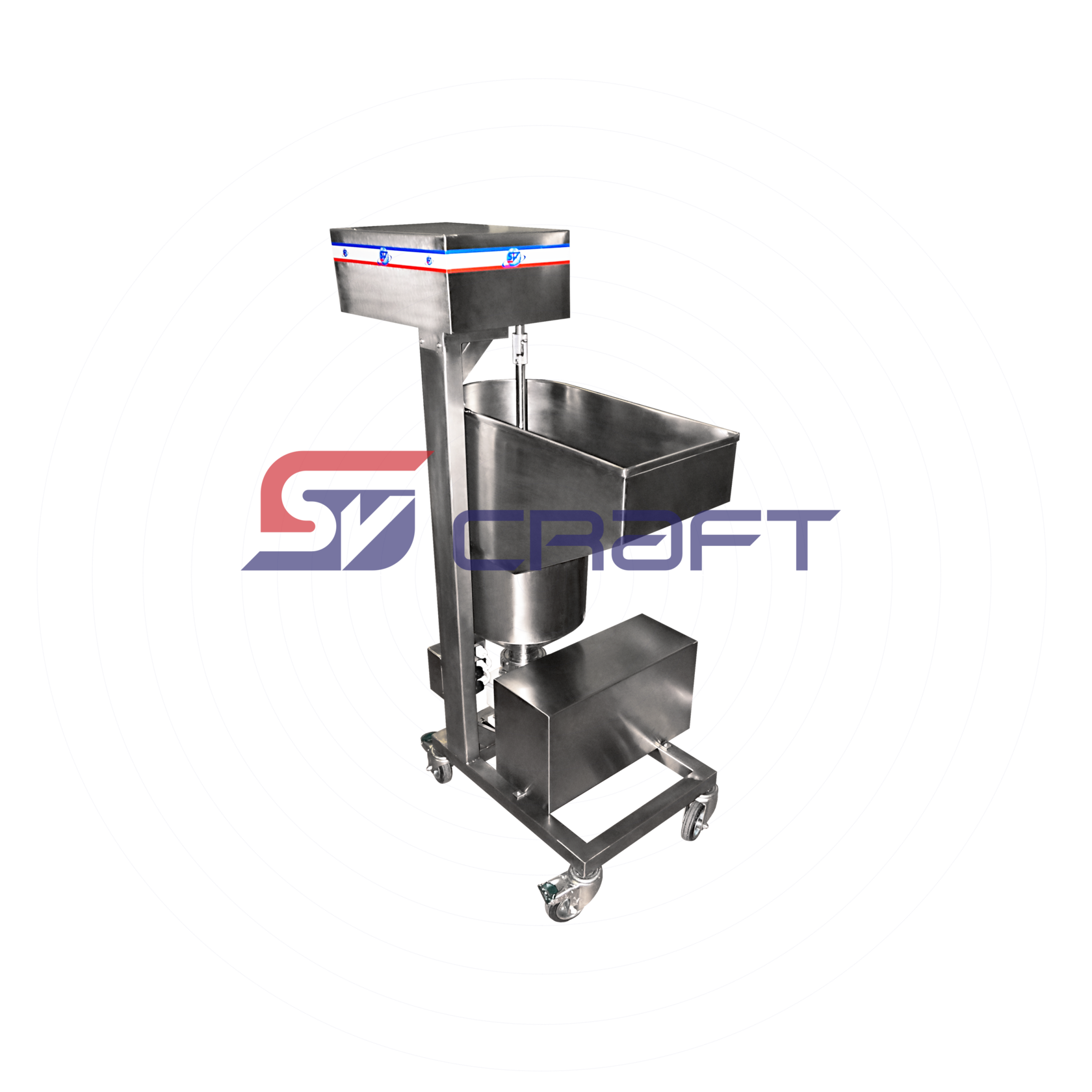

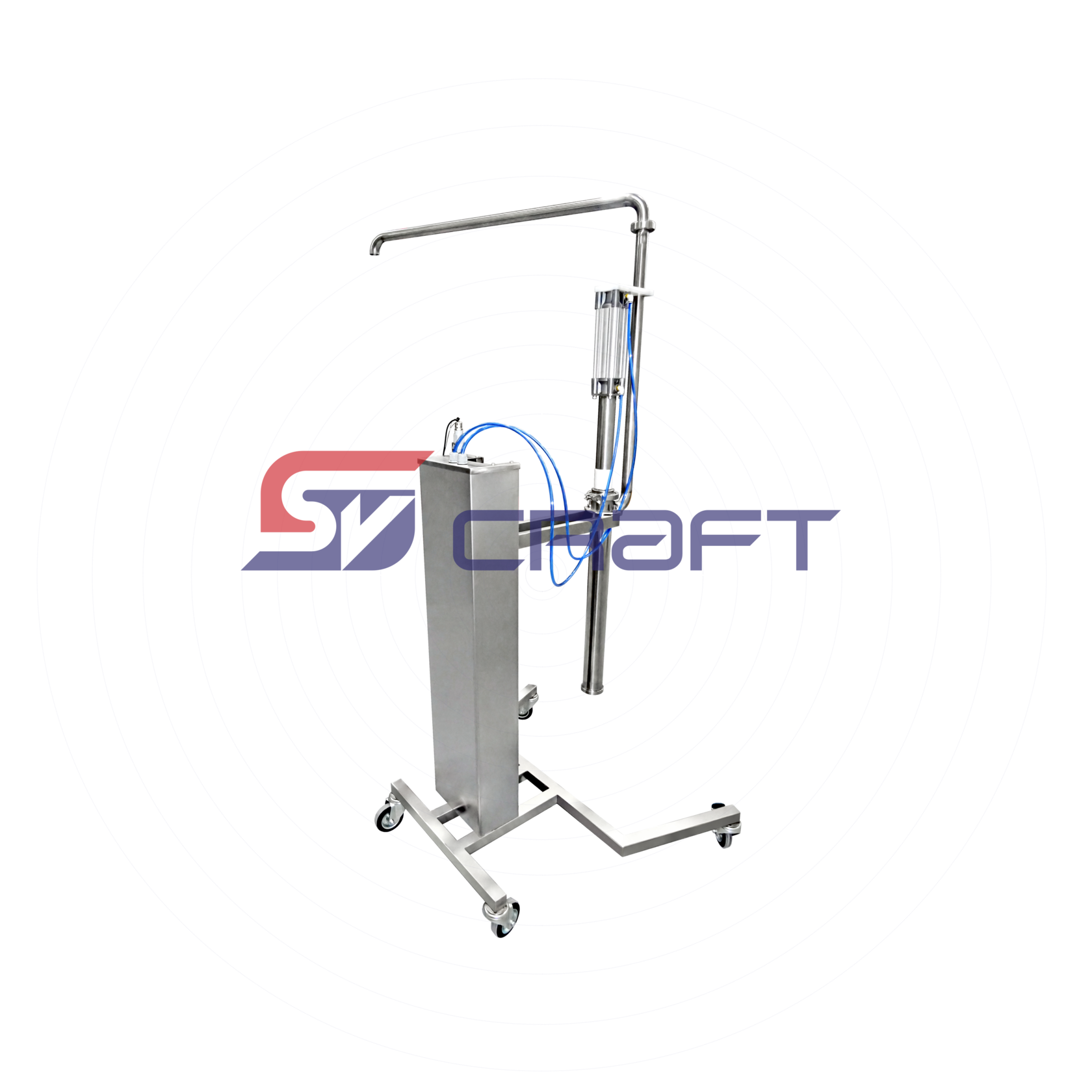

A universal screw extruder with a gear-type filling dispenser is available as a complete set, both on the oven floor and embedded on the cooling tunnel belt. Productivity from 200 to 500 kg / hour (depending on the size and shape of the product) and an extensive range of products created on such a machine will optimize production processes, facilitate the work of personnel and reduce production costs.

In the configuration of the oven "RoboExtruder" forms: oatmeal cookies, custard gingerbread with filling, two-color gingerbread with and without filling, raw gingerbread with filling.

Built-in feed cooling tunnel "RoboExtruder" forms: products masses of the type of Hematogen, domed candy products with liquid fillings, products with szufladami fillings, products made from assorted chocolates mass products type of nougat, theater fondant, items of crushed fruit mass. As well as sweets from dried fruits in glaze: prunes, dried apricots, figs, dates, etc.

In the configuration of the oven "RoboExtruder" forms: oatmeal cookies, custard gingerbread with filling, two-color gingerbread with and without filling, raw gingerbread with filling.

Built-in feed cooling tunnel "RoboExtruder" forms: products masses of the type of Hematogen, domed candy products with liquid fillings, products with szufladami fillings, products made from assorted chocolates mass products type of nougat, theater fondant, items of crushed fruit mass. As well as sweets from dried fruits in glaze: prunes, dried apricots, figs, dates, etc.

Price on request

In stock

RoboExtruder extrusion molding machine

Additional options

Hopper heating

String cutting

Screw chamber heating

Diaphragm

cutting

cutting

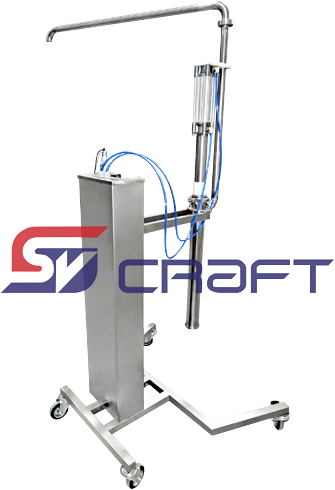

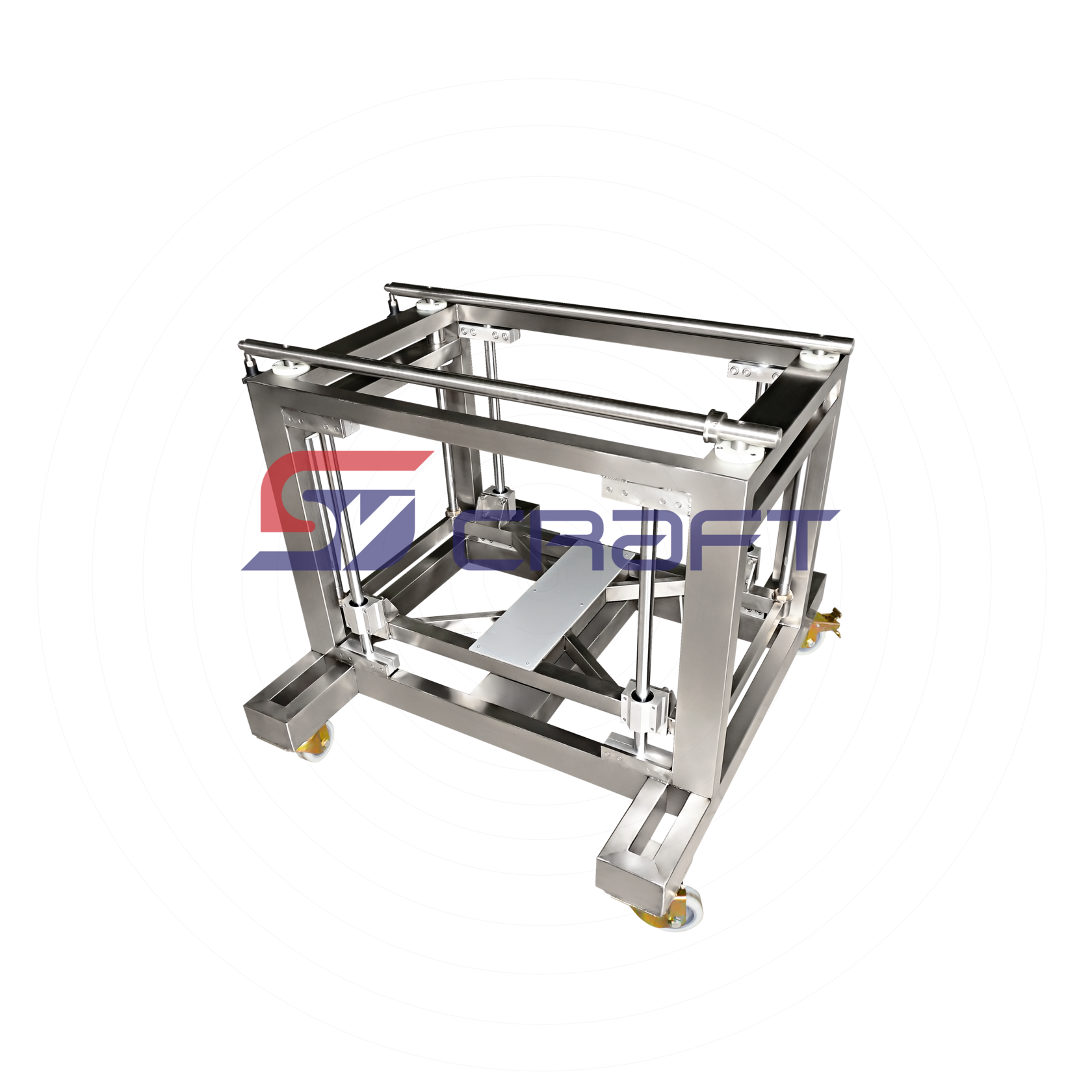

Trolley for

removing the head

removing the head

A universal screw extruder with a roller-gear type filling dispenser is available as a complete set, both on the furnace floor and embedded on the cooling tunnel belt. Productivity from 200 to 500 kg / hour (depending on the size and shape of the product) and a wide range of products created on such a machine will optimize production processes, facilitate the work of personnel and reduce production costs.

In the configuration of the oven "RoboExtruder" forms: oatmeal cookies, custard gingerbread with filling, two-color gingerbread with and without filling, raw gingerbread with filling.

Built-in feed cooling tunnel "RoboExtruder" forms: products masses of the type of Hematogen, domed candy products with liquid fillings, products with szufladami fillings, products made from assorted chocolates mass products type of nougat, theater fondant, items of crushed fruit mass. As well as sweets from dried fruits in glaze: prunes, dried apricots, figs, dates.

In the configuration of the oven "RoboExtruder" forms: oatmeal cookies, custard gingerbread with filling, two-color gingerbread with and without filling, raw gingerbread with filling.

Built-in feed cooling tunnel "RoboExtruder" forms: products masses of the type of Hematogen, domed candy products with liquid fillings, products with szufladami fillings, products made from assorted chocolates mass products type of nougat, theater fondant, items of crushed fruit mass. As well as sweets from dried fruits in glaze: prunes, dried apricots, figs, dates.

Price on request

In stock

RoboExtruder extrusion molding machine

Additional options

Hopper heating

String cutting

Screw chamber heating

Diaphragm

cutting

cutting

Trolley for

removing the head

removing the head

Оставьте заявку

PRODUCTS PRODUCED ON THIS EQUIPMENT

PRODUCTS PRODUCED ON THIS EQUIPMENT

Video

Video

Basic features of RoboExtruder

Basic features of RoboExtruder

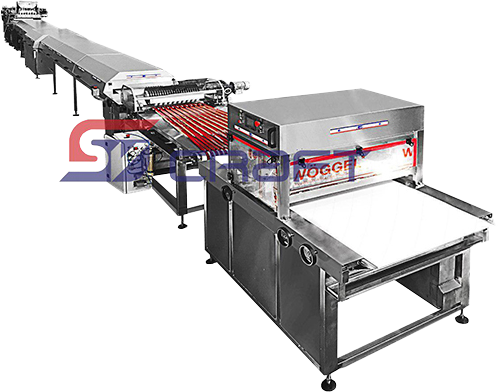

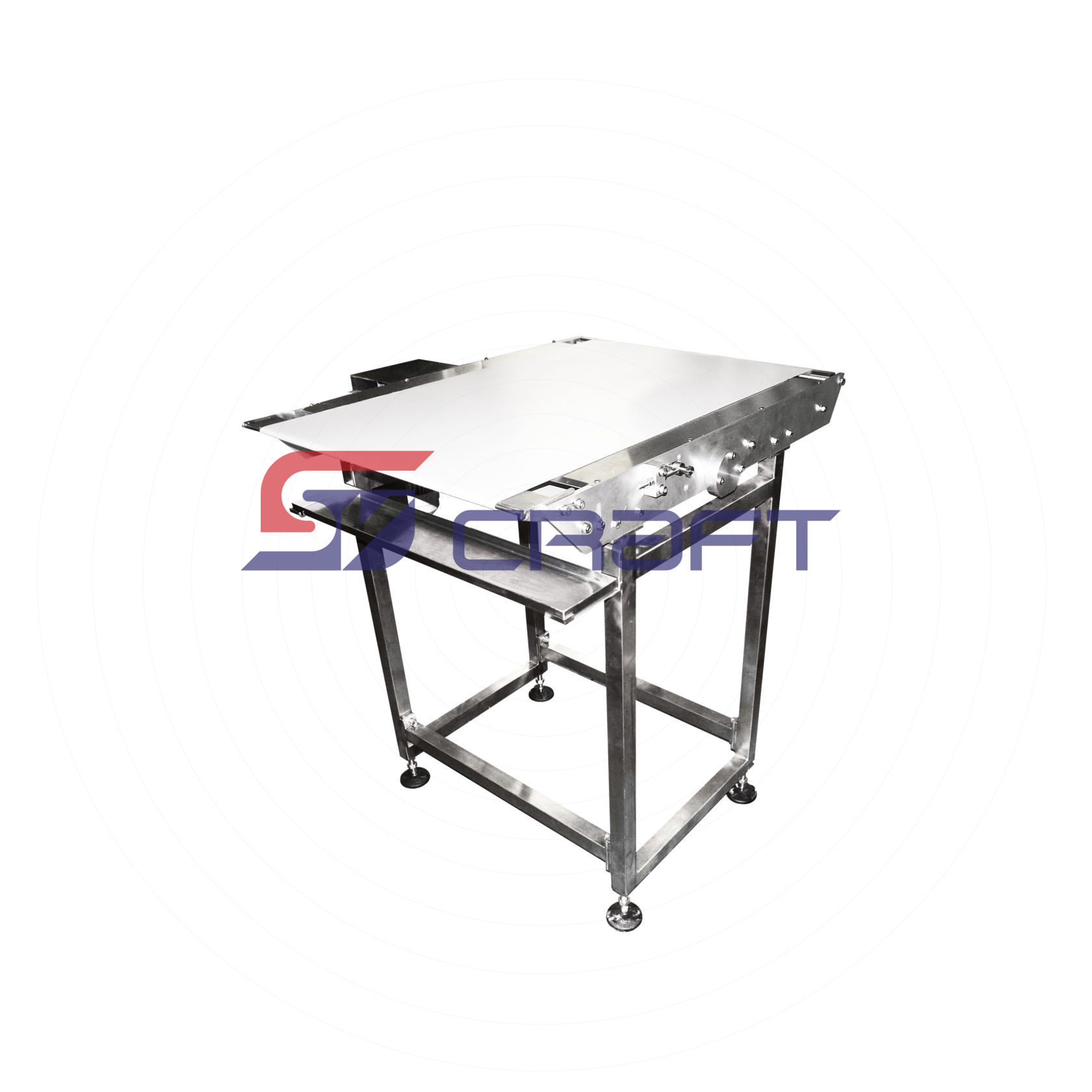

The principle of operation of the "RoboExtruder" extrusion molding machine is based on screw injection. Augers work with a diaphragm cutting mechanism, which in turn expands the range of work with the mass. The filling is fed by a gear pump with separated chambers. This equipment for confectionery production is installed at the entrance of the oven for the production of cookies and gingerbread, or at the entrance of the cooling tunnel for the production of sweets and bars. To produce various flat products, the machine is equipped with a string cutting device. To obtain products by laying out the harness on the tape, the machine is equipped with a guillotine cutting device.

1

Reinforced screw block for mass delivery

2

Pressure device

3

Possibility to refill the hopper in the extruder using a conveyor

4

The extruder can be installed either at the end of the cooling tunnel or above the cooling tunnel belt

5

The machine is controlled from the touch screen

5

Heating of the screw chamber hopper

The principle of operation of the "RoboExtruder" extrusion molding machine is based on screw injection. Augers work with a diaphragm cutting mechanism, which in turn expands the range of work with the mass. The filling is fed by a gear pump with separated chambers. This equipment for confectionery production is installed at the entrance of the oven for the production of cookies and gingerbread, or at the entrance of the cooling tunnel for the production of sweets and bars. To produce various flat products, the machine is equipped with a string cutting device. To obtain products by laying out the harness on the tape, the machine is equipped with a guillotine cutting device.

1

Reinforced screw block for mass delivery

2

Pressure device

3

Possibility to refill the hopper in the extruder using a conveyor

4

The extruder can be installed either at the end of the cooling tunnel or above the cooling tunnel belt

5

The machine is controlled from the touch screen

6

Heating of the hopper and screw chamber

Technical parameters

Technical parameters

*Specified after filling in the customer's technical specification